What are the requirements for the cooling and heating temperature control equipment of the 500-liter

The 500-liter reaction kettle cooling and heating temperature control equipment is a dynamic temperature control system, a fully closed circulation pipeline, which can be automatically heated or cooled according to the process requirements.

1. A series of exothermic and endothermic reactions will occur during the polymerization reaction of the 500-liter reactor with cooling, heating and temperature-controlling equipment.

2. It can control one or more reactors at the same time. It is a large system device with integrated temperature control, which can be produced according to the requirements of working conditions.

3. During the chemical reaction, it is recommended that the surrounding operators do not get too close to avoid some troubles. During the reaction process, if the heat is not removed in time, the reaction pressure will be affected. If the pressure is too high, the whole reaction will be in some danger.

4. When selecting, it needs to be selected according to the size, weight, type of the reactor and the volume of the jacket or coil. The heat ratio and viscosity of the materials in the reactor are closely related.

5. The size of the jacket or coil needs to be calculated to estimate the time required for temperature control. Users can customize whether explosion-proof or isolation is required according to their needs.

6. It can be equipped with reactors of different volumes for refrigeration, heating and temperature control. Since reactors of different sizes bring different heat capacities, their endothermic or exothermic capacities are also different.

7. Parameter configuration After the user provides the manufacturer with accurate operating data, the corresponding cooling and heating temperature control scheme will be provided after calculation, and the corresponding cooling and heating control scheme will be provided after calculation. In the scheme, the specific model and parameter configuration will be selected, and the user can see the brand of each accessory in the parameter configuration.

8. Improper selection of the model will slightly affect the running time of the equipment, resulting in an increase in the cost of use, and in severe cases, the equipment will not be able to run and use.

Therefore, the 500-liter reactor cooling and temperature control equipment needs to provide accurate working conditions such as reactor size, temperature requirements, materials, etc., so as to avoid the selection of large or small equipment that cannot meet the expected temperature requirements.

Recomendaciones relacionadas

-

How to Maintain Low Temp Chillers

989Low temp chiller is a kind of refrigeration mechanical equipment which needs to be used in many industrial production operations. It can provide very good refrigeration technology for different production operations and ensure the smooth progress ...

Ver detalles -

Compressor key protection of reactor temperature control system

1250In the operation of the reactor temperature control system, the compressor is the core part, and its performance is more important. Therefore, it is necessary to protect the compressor. Under normal working conditions, the compressor of the temper...

Ver detalles -

Cooling simulation system for battery pack extreme performance test

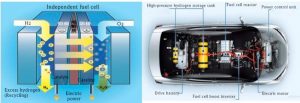

1132With the development of technology, pure electric vehicles are becoming more and more common, but pure electric vehicles are difficult to get a better solution in terms of cruising range, charging speed, and pollution after battery waste. This mak...

Ver detalles -

How to deal with the cooling problem of large quick-freezer compressors?

1376There are many types of compressors in large-scale quick-freezers, and the brands and models of compressors are different according to different models. Once the compressor temperature is too high, it may cause some failures, so cooling is also an...

Ver detalles

LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor