How to reduce the condensing pressure of the heating circulator unit?

During the operation of the heating circulator unit, the temperature change inside the equipment will cause the condensing pressure to change. Especially in summer when the condensing pressure is too high, the power consumption of the compressor will continue to increase, resulting in a gradual decrease in the cooling capacity, which indirectly makes the equipment cycle worse. It is necessary to appropriately reduce the condensing pressure.

1. Then, when the condensing pressure of the heating circulator unit is too low, the power supply of the throttle valve is insufficient, and the high-pressure liquid pipe is continuously affected by the heating factor, which will reduce the capacity of the throttle valve.

2. The pressure of the condenser can be controlled by adjusting the heat exchange capacity of the condenser. When the heat exchange of the condenser is large, the gas discharged from the compressor is fully condensed, and the condensing pressure gradually decreases; if the heat exchange performance of the condenser is weakened, the condensing pressure continues to rise.

3. The condenser can adjust the cooling water flow to control the condensation pressure. Install a regulating valve on the condenser cooling water outlet pipe. There are two modes for the water volume control valve: one is a temperature type water volume control valve that uses the temperature at the outlet of the cooling water of the condenser to indirectly send a letter. It has a temperature sensor that is inserted into the condensate outlet. When the water temperature rises, the valve opens large; when the water temperature decreases, the valve closes small. The other is a pressure-type water volume regulating valve that directly sends a signal from the condensing pressure, and the pressure signal is drawn from the condenser. When the condensing pressure gradually increases, the valve opens large; when the condensing pressure decreases, the valve closes small, thereby changing the cooling water flow of the condenser.

4. The self-contained cooling tower circulation system can be used. In order to prevent the condensation pressure from being too low, it can be adjusted by the water bypass valve, which makes part of the water from the condenser sent to the cooling tower for cooling, and the other part is returned to the bypass. water outlet.

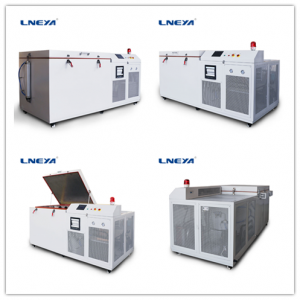

For the LNEYA heating circulator unit, if multiple pumps are used in parallel, the number of running pumps can be changed to adjust the flow rate according to the constant change of the condensing pressure.

Recomendaciones relacionadas

-

Análisis de los motivos de la no refrigeración de los equipos de refrigeración criogénica

1069Los equipos de refrigeración de temperatura ultra baja se utilizan principalmente en el procesamiento de frío industrial. A diferencia de algunos fabricantes de equipos de refrigeración de temperatura ultrabaja, los equipos de refrigeración de temperatura ultrabaja de LNEYA utilizan...

Ver detalles -

Cómo prolongar la vida útil del sistema de refrigeración por glicol?

991Para prolongar la vida útil de su enfriadora de glicol en aplicaciones industriales, preste atención a los siguientes puntos: 1. No utilice anticongelante para automóviles o anticongelante no cualificado. Debido a que este ...

Ver detalles -

¿Qué importancia tiene el aislamiento de la enfriadora?

1284Respuesta: Para el enfriador, si se opera a alta temperatura, una gran cantidad de aire frío en el enfriador industrial puede ser severamente perdido. Después de que el efecto de sellado del entorno de uso, a través de la preservación del calor oportuna y eficaz, la operati...

Ver detalles -

Price Analysis of High Low Temperature Test Chambers

1033As the saying goes, “ You get what you've paid. ” The price of the high low temperature test chamber is related to the quality of its configuration. The technology of Wuxi LNEYA itself is priceless. In the test chamber industry, the high low tempe...

Ver detalles

LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor