Unidad de control térmico de reactores y soluciones para productos químicos

El control de la temperatura es un proceso en el que se mide o detecta la temperatura de una sustancia o un cambio de temperatura, y se ajusta la transferencia de energía térmica hacia o desde el espacio o la sustancia para alcanzar la temperatura deseada....

When dealing with pharmaceutical production, maintaining accurate temperature control is critical. Starting with research throughout production, precise temperature control is required at every stage of the process. We fully understand the importance of process cooling, and simple temperature fluctuations (positive and negative) can ruin research or production.

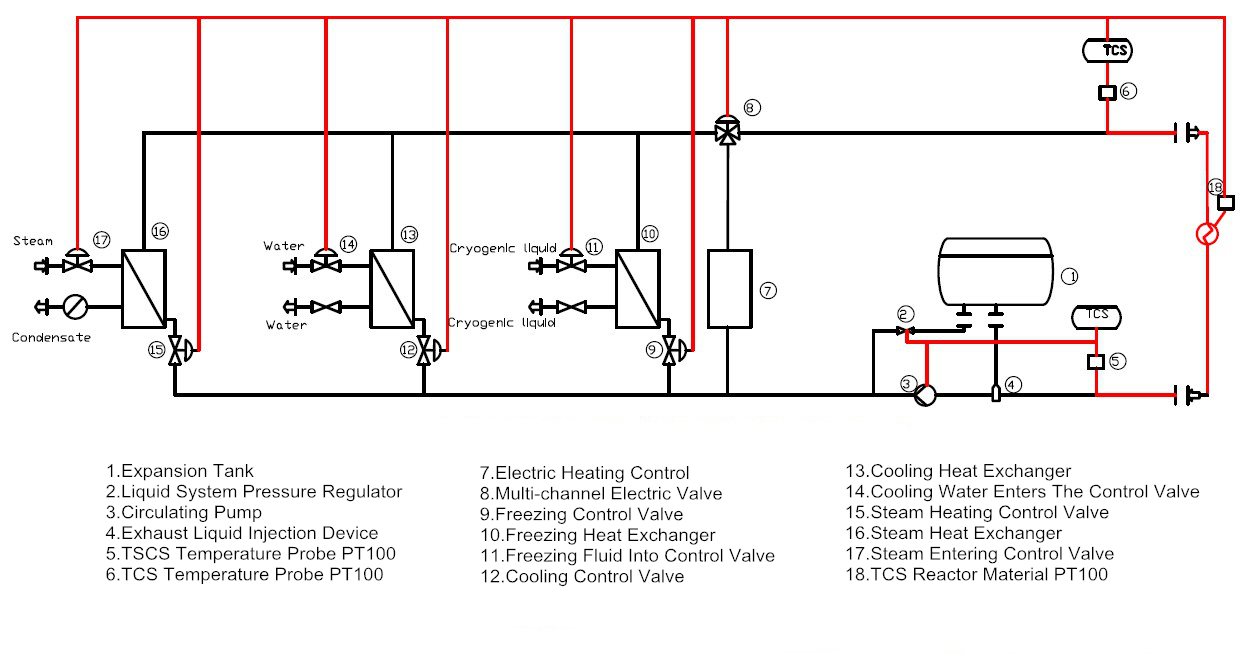

Our TCU can meet all your heating, cooling and temperature control needs for your chemical or pharmaceutical reactor. The LNEYA-TCU temperature control system can utilize existing thermal energy (such as steam, cooling water and ultra-low temperature liquids-the “primary system”) infrastructure integration to achieve dynamic temperature control of the equipment temperature in a single fluid system or a secondary circuit. This only completes the flow of a heat transfer liquid into the jacket of the reaction vessel (rather than directly into the steam, cooling water or cryogenic liquid), and the temperature of the entire reaction process is controlled by calculation.

From -120°C for cryogenic pharmaceutical applications to 300°C for chemical applications, the maximum temperature can be set according to the supplier’s heating or cooling source. The maximum temperature range can be set using a glycol water formula. Through three-point sampling (material temperature point, outlet temperature of temperature control system, inlet temperature of temperature control system), and our own model-free self-building algorithm and general anti-lag cascade algorithm, the problem of large drug delays is solved. Chemical temperature control . Our SR series and ZLF series are completely suitable for low temperature reaction, synthesis, separation process, pilot plant, reactor system, autoclave, combinatorial chemistry, etc.

This will increase product profitability and reactor utilization, and reduce energy and plant operating costs. Our TCU is fully automated and easy to operate. The temperature control accuracy of the product is ± 0.5 ° C, and the cooling power can be provided from 0.5 kW to 1200 kW.

The picture below shows the TCU thermal control unit customized by domestic customers

Recomendaciones relacionadas

-

¿Cuáles son las características de refrigeración de las enfriadoras industriales?

1167If there is a high temperature difference between the inlet and outlet water, then a large external tank will be used to store cold water. In this case, the cooling water will not be directly from the cooler application. Deep into the outside of t...

Ver detalles -

What is the function of high temperature heat transfer fluid system?

999The high temperature heat transfer fluid system adopts a fully closed circulation system, so that there is no oil mist during high temperature operation, and high temperature refrigeration can be realized. It is the temperature control equipment u...

Ver detalles -

The importance of car cooling water cycle maintenance

1078Even if the overall running quality of the car cooling water circulation machine is high, if there is no maintenance and maintenance in the specified time, the car cooling water circulation machine may have different degrees of failure. Especially...

Ver detalles -

Precautions for the use of cooling and heating circulation device for lithium battery testing

983As a professional experimental test auxiliary instrument, the cooling and heating circulation device for lithium battery testing is the circulating supply end of the cold source and the heat source, with a wide operating range. It is used in pharm...

Ver detalles

LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor