Detalles del dispositivo de protección del dispositivo de control de la temperatura del fluido circulante

The circulating pump overload protection function is to cut off the main power of the circulating pump when the circulating liquid temperature adjustment device is too large. Press the green button when resetting; the red button is the stop button, which is used during the test. When frequent protection, please check whether the voltage is under voltage (undervoltage is less than 15%, the power protector is not working), undervoltage is increased into current, forming protection. At this time, a Phillips screwdriver can be used to adjust according to the “△” direction. Current.

Different circulating fluid temperature adjustment devices are equipped with different high and low voltage protectors. The high and low pressure protectors will protect the compressor with reference to the suction and exhaust pressure of the compressor to ensure the normal operation and operating life of the compressor. The high and low voltage protectors are divided into mechanical and electronic high and low voltage protectors. When the high and low voltage protectors are protected, manual reset is required. Press the red highlight button to reset. When the high and low voltage protectors generate protection, manual reset is required. Push the red arrow to reset. The electronic high and low voltage protector is automatically reset.

The circulating fluid temperature adjustment system provides a lot of accessories for equipment protection to ensure the safety and stability of the equipment. The over temperature protection has an independent high temperature temperature limit switch, which can set a relatively large temperature value through this temperature switch (please note) Meet the relatively large operating temperature range of the equipment and the temperature range of the heat transfer oil).

Inspiratory temperature protection with independent compressor suction temperature protector to protect the compressor from excessive suction temperature, ensure that it is within 65 °C (non-recycling liquid temperature adjustment device manufacturer authorization, do not modify, will directly affect the compressor Cooling capacity).

Circulating fluid temperature adjustment device The oil pressure difference protector is generally applied in large equipment. Depending on the equipment, the oil pressure difference protector is different. Press the upper ink green button when resetting. Other types of oil pressure difference protectors are similar. The reset button can be reset by itself. Other protections of the circulating fluid temperature adjustment device include phase protection, phase loss protection, overvoltage and undervoltage protection, leakage protection, and water shutoff protection.

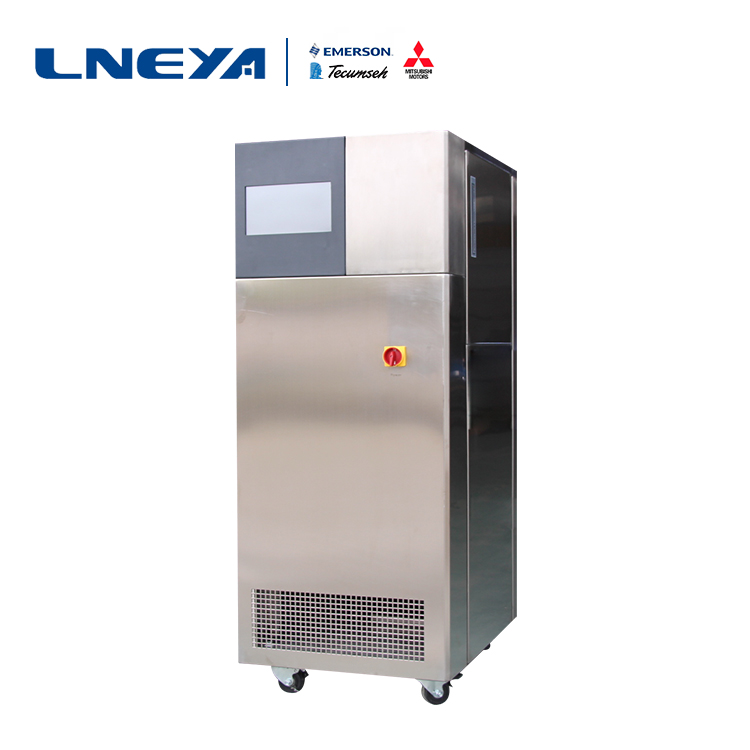

The protection devices of different circulating liquid temperature adjustment devices are different. No matter what brand, the safety devices are more important. We need to pay attention to them. We must carefully check before purchasing to ensure the operation of the equipment.

Recomendaciones relacionadas

-

There are usually three ways to control the temperature of laboratory reactors

9141. Manual control: Manually operate the knob on the front of the reactor controller.2. Control by PC: The PC and the controller are connected by a network cable, and the operation is carried out on the PC.3. Controlled by thermostat: Silicone oil...

Ver detalles -

Trouble shooting method for refrigeration device of air-cooled cold water mechanism chemical reactio

1119If air enters into the air-cooled coldwater mechanism refrigeration unit system of the chemical reaction kettle, theimpact will be many. Enter the air circulation system first, the pressure willrise, the heat dissipation effect of the condenser...

Ver detalles -

What are the applications of steam circulators in chemical industry?

964The steam circulator in the chemical industry is a temperature control equipment in the pharmaceutical and chemical industry. When users operate, they need to understand the performance and maintenance knowledge in order to operate the equipment e...

Ver detalles -

Component and component tester for special environments

1605With the continuous development of the semiconductor industry, component component testing has been widely used in components in the fields of industry, scientific research, pharmaceuticals, and chemical industry. At present, there are quite a few...

Ver detalles

LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor