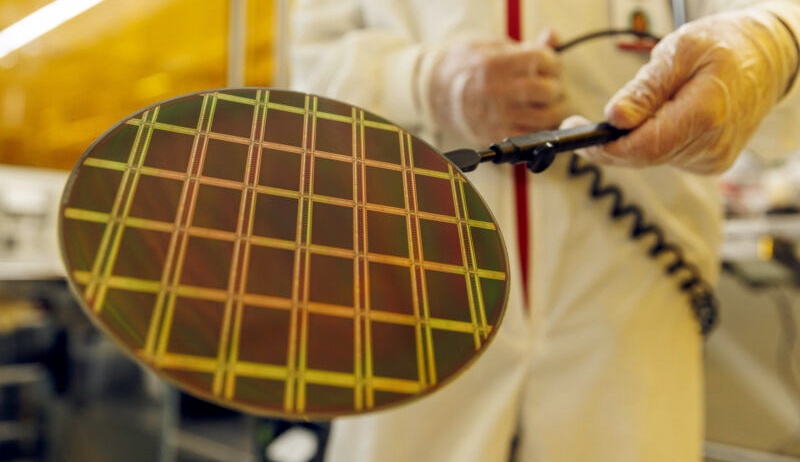

¿Por qué los gases especiales utilizados en los procesos de fabricación de semiconductores requieren refrigeradores?

If you have any questions, please contact us

When using special gases in semiconductor manufacturing processes, a chiller is required, mainly due to the following reasons:

- Gas purity control: Special gases are used as raw materials in semiconductor manufacturing, and their purity is crucial to the performance of the final semiconductor device. Some special gases are prone to decomposition or react with impurities such as oxygen and water vapor at high temperatures, reducing their purity. The low-temperature environment provided by the chiller helps maintain the purity of gas during storage and transportation.

- Gas transportation and storage: Some special gases are easy to store in a liquefied state

Transportation, chillers can be used to cool gases to low temperatures, liquefy them, and facilitate storage and metering. Meanwhile, a low-temperature environment is beneficial for slowing down the natural evaporation rate of gases and reducing losses.

3. Process requirements: In semiconductor manufacturing processes such as chemical vapor deposition (CVD), physical vapor deposition (PVD), atomic layer deposition (ALD), etc., gas needs to go through a pre-treatment system, including a cooling system, before entering the reaction chamber to maintain gas transport at a specific temperature and prevent gas preheating or premature reaction in the pipeline.

4. Equipment cooling: Semiconductor production equipment generates a large amount of heat during operation, and requires a chiller to provide cooling for its internal gas delivery pipelines, reaction chambers, and other components to ensure that the gas maintains a stable temperature when entering and leaving the chamber. This is crucial for precise process control and product quality.

5. Safety considerations: Some special gases may become unstable or flammable and explosive at high temperatures. Using a chiller can reduce the risk of gas leakage accidents and ensure the safety of the entire process.

Therefore, the chiller is crucial for the storage, treatment, and use of special gases in the semiconductor manufacturing process, and is one of the key equipment to ensure the smooth progress of the semiconductor manufacturing process.

Solicitar un presupuesto

Proporcionar 7 * 24 consulta gratuita y soluciones integrales

Recomendaciones relacionadas

-

How to use industrial water chiller to reduce environmental pollution

785With the continuous development of chemicaland pharmaceutical industries, environmental pollution is put on the agendaearlier. As an manufacturer of which is the industrial water chiller, I can saythat except for corresponding to the environmen...

Ver detalles -

Motor test chiller compressor causes wear

1064Motor testing chiller oil quality may be one of the main reasons affecting crankshaft wear. If the engine oil is used in the chiller refrigeration system, the engine oil that does not meet the requirements and is of poor quality may cause cranksha...

Ver detalles -

5L glass reactor thermal oil heating system

7265L glass reactor is a common laboratory equipment used for various chemical reactions. In order to ensure that the reaction is carried out at the required temperature, it is usually necessary to equip it with a heating system. Thermal oil (a...

Ver detalles -

ISG/TM Motor Test Cooling System High Voltage Failure and Treatment Measures

1208The ISG/TM motor test cooling system is divided into two types in the industry: air-cooled and water-cooled. The working principle is to first inject a certain amount of water into the water tank in the machine, and then pass the ISG/TM motor test...

Ver detalles

LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor

Someter a consulta

Le responderemos en 24 horas