Semiconductor FAB Process Temperature Control

LNEYA has rich experience in temperature control of semiconductor industry products, and its products cover various process temperature control such as lithography, etching, thin film deposition, polishing, etc.

Products include: high-precision chiller heater, low-temperature Chiller, compressor-free heat exchange unit, etc., with temperature control accuracy up to ±0.05℃

SOLUCIÓN

Semiconductor manufacturing is an extremely environmentally demanding process, and many process steps are very sensitive to temperature.

For example, in the photolithography process, the optical system of the photolithography machine needs to work in a stable temperature environment, because a slight change in temperature may cause deviations in the optical path, which in turn affects the accuracy of the photolithography. In processes such as chemical vapor deposition (CVD) and physical vapor deposition (PVD), the reaction temperature directly affects the quality and performance of the film. Accurate temperature control can ensure that the deposited film has uniform thickness and accurate composition, thereby improving the performance and yield of the chip.

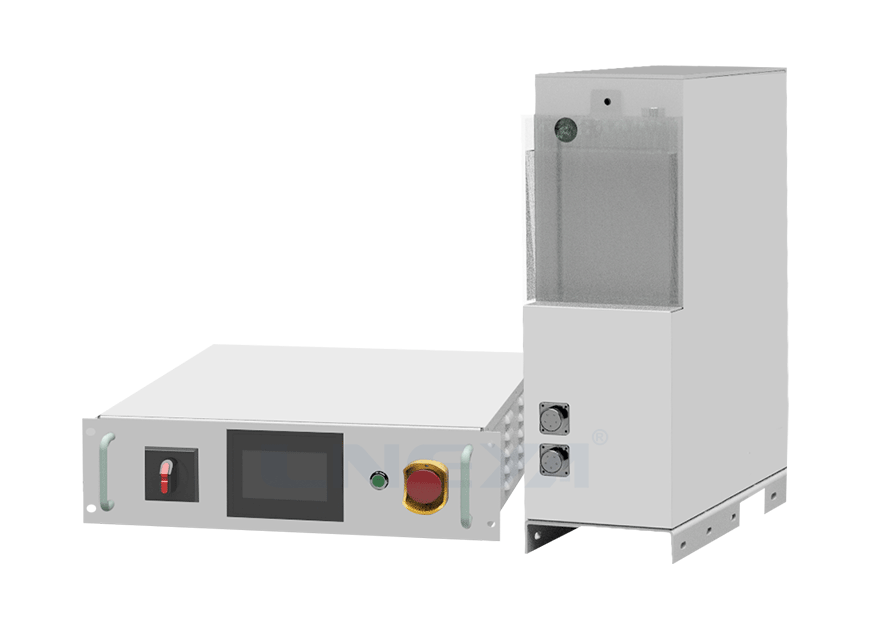

FLTZ Variable Frequency Enfriador

—Temperature control accuracy ±0.05℃ (Outlet temperature steady state)

-90~+100℃, utilizado principalmente para el control preciso de la temperatura en los procesos de producción y ensayo de semiconductores. La empresa aplica diversos algoritmos en el sistema para lograr una respuesta rápida del sistema y una gran precisión de control.

Enfriadores de doble canal

—Precise temperature control for multiple fluid channels

FLTZ series dual-channel Chillers are mainly used for precise control of reaction chamber temperature in semiconductor manufacturing processes. The company applies multiple algorithms (PID, feedforward PID, model-free self-building tree algorithm) in the system to significantly improve the system’s response speed, control accuracy and stability.

Three channel chillers

—Triple channel chiller independent intelligent control

FLTZ series three-channel chillers are primarily used for precise temperature control during semiconductor production and testing. The system supports independent temperature control of three channels, each with its own temperature range, cooling and heating capabilities, and thermal medium flow rate.

Thermoelectric Enfriador Peltier

—PRECISIÓN DE TEMPERATURA ±0.1℃

Dynamic temperature control of the electrostatic chuck (ESC) enables its application in all types of etching processes.

Fast and precise temperature control meets the most demanding process requirements.

Chiller Heat Exchange Series

—No compressor is used

ETCU sistema de intercambio de calor sin compresor, el sistema puede ser universal tanque de expansión, condensador, sistema de agua de refrigeración, etc, que puede reducir eficazmente el tamaño de los equipos y reducir el número de pasos de funcionamiento.

Aire acondicionado de precisión

—Constant temperature and humidity unit

The equipment, production processes, inspection procedures, and spaces used in manufacturing facilities for semiconductors, liquid crystal displays, and solar panels require highly accurate and stable air handling. LWM series precision air conditioning units eliminate the high costs of area-wide air handling and maintenance.

LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor