cámara de prueba de baterías

GD -40℃~+100℃

Se aplica principalmente en el campo de las baterías de nueva energía. La cámara de prueba de baterías proporciona un entorno de prueba con control de temperatura de alto a bajo, así como control del flujo y la presión para las muestras de baterías de nueva energía.

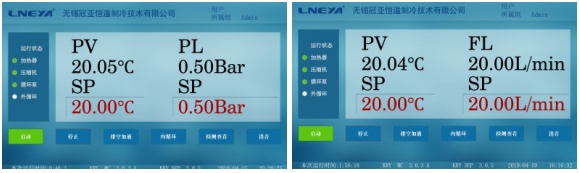

LNEYA’s battery test chamber adopts a double-layer design for high and low temperature control. Currently,The temperature control range of antifreeze and chamber is -40℃~+100℃. The environmental chamber for battery testing can provide a temperature range of -45℃~+100℃. The flow rate control range of antifreeze is 1L/min~25L/min.C

| Modelo | GD-9000-2-B1-KRYCH-4A15W | GD-9000-2-B1-KRYCH-475W | GD-9000-2-B1-KRYCH-4A10W | GD-1000-B1-KRYCH-475 | |||||

| Control del caudal de anticongelante | 1L/min~40L/min | 1L/min~25L/min | 1L/min~25L/min | 1L/min~10L/min | |||||

| ±0.2L/min | ±0.2L/min | ±0.2L/min | ±0.2L/min | ||||||

| Presión anticongelante | Medir y mostrar la presión de entrada y salida, así como la presión mostrada en la pantalla táctil | ||||||||

| Potencia calorífica | 15 kW | 14 kW | 7,5 kW | 14 kW | 10kW | 14 kW | 7,5 kW | 6kW | |

| Capacidad de enfriamiento del anticongelante | 135℃ | 15 kW | 7,5 kW | 10KW | 7,5 kW | ||||

| 20°℃ | 15 kW | 7,5 kW | 10KW | 7,5 kW | |||||

| 0℃ | 15 kW | 7,5 kW | 10KW | 7,5 kW | |||||

| -20℃ | 10kW | 4,5 kW | 6KW | 4,5 kW | |||||

| -35℃ | 4kW | 1,8 kW | 2,5 KW | 1,8 kW | |||||

| Precisión del control de temperatura del anticongelante | ±0.1℃ | ||||||||

| Uniformidad de temperatura | ≤±1℃(unloaded) | ||||||||

| Cooling water 20 ℃ | 25m³/H | 20m³/H | 20m³/H | 7m³/H | |||||

CAN/TCP/RS485

Bomba de accionamiento magnético

380V 50HZ

Ventajas de la cámara de prueba de baterías

Material de la tubería

El material de la tubería de la unidad industrial de chiller calefactor WTD es SUS304, que tiene mayor resistencia a la corrosión atmosférica, a la oxidación y al calor, proporcionando a su chiller una vida útil más larga y menores costos de mantenimiento.

Espacio en el suelo

El chiller calefactor recirculante WTD utiliza un intercambiador de calor de placas con una estructura compacta y una huella pequeña, lo que es adecuado para lugares con espacio limitado. La parte inferior está equipada con 4 ruedas, lo que facilita moverlo según sus necesidades.

Accesorios principales

Los accesorios del chiller calefactor industrial WTD son básicamente de marcas reconocidas internacionalmente. Por ejemplo, el compresor utiliza Secop, Emerson Copeland y Tecumseh de Francia; el filtro seco utiliza Danfoss; el contactor/disyuntor utiliza Schneider.

La bomba de frecuencia variable puede ajustar la presión hidráulica de circulación y el caudal para lograr un control de alta precisión del rango total de 5% a 100%.

(La presión de salida y el caudal del fluido circulante pueden ajustarse en el panel de control. Incluso bajo diversas condiciones de tuberías del cliente, sin ajuste de tuberías de derivación, la presión de salida establecida puede ser controlada automáticamente por la bomba de frecuencia variable. Esto puede reducir el consumo de energía de la bomba.)

TODAS las cámaras de pruebas ambientales modelo

GD -40℃~100℃

cámara de prueba de baterías

Potencia frigorífica 1,8 kW~15 kW

Potencia de calefacción 6KW~15KW

Temperature uniformity ±1℃

GD -80℃~150℃

cámara de pruebas climáticas

Heating rate (+20~+150℃)A:5℃/min

Cooling rate Carrying idler (+20~-40℃)5℃/min

GD -40℃~180℃

cámara de choque térmico

Low temperature -40~0℃

High temperature +60~+150℃

Temperature fluctuation ≤1℃

You can trust our cámara de prueba de baterías factory

Como líder en la industria de la refrigeración, LNEYA siempre concede gran importancia a la innovación tecnológica. LNEYA cuenta con más de 90 patentes de invención, y 20% de sus más de 400 empleados son técnicos. El proceso de producción adopta la plataforma de diseño PLM de Siemens para gestionar uniformemente todos los datos en todo el ciclo de vida del producto, desde el diseño, la venta, la producción, la posventa hasta el desguace, para maximizar la trazabilidad de la calidad del producto.

Servicio global

Atendido a más de 30,000 clientes.

Exportado a más de 20 países.

Patentes de certificación

Ha obtenido la certificación CE, la certificación SGS y la certificación ISO.

Servicio postventa

Proporcionar formación técnica integral.

Con soluciones 24/7.

Equipo profesional

Fundada en 2010, con 15 años de experiencia en la industria.

El 20% de los empleados son técnicos.

Control de calidad

Inspección visual.

Prueba de rendimiento.

Prueba de seguridad eléctrica.

Póngase en contacto con nuestros expertos en cámaras de prueba de baterías

Contacte con LNEYA

Envíenos su solicitud y nos pondremos en contacto con usted en un plazo de 24 horas

LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor