Todos los modelos de enfriadores automotrices

KRY -40℃~100℃

Enfriadores de baterías

Refrigeración por agua y aire

Capacidad de calefacción 2,5 kW~60 kW

Capacidad de enfriamiento 1,2 kW~60 kW

Precisión de temperatura ±0,3℃

KRYZ -40℃~100℃

Enfriador de anticongelante

Refrigeración por agua y aire

Capacidad de calefacción 2,5 kW~38 kW

Capacidad de enfriamiento 1,8 kW~60 kW

Precisión de temperatura ±0,3℃

KRY -40℃~100℃ Multicanal

Chiller de enfriamiento líquido

Refrigeración por agua y aire

Capacidad de calefacción 7,5 kW~25 kW

Capacidad de enfriamiento 1,8 kW~25 kW

Precisión de temperatura ±0,1℃

KRYZ -40℃~50℃

Sistema de refrigeración de paquete de baterías

Capacidad de enfriamiento 0.5kW~10kW

Capacidad de calefacción 0.5kW~10kW

Precisión de temperatura ±0.5℃

KRYO 0℃~160℃

enfriador de aceite

Potencia de calefacción 15 kW~38 kW

Capacidad de enfriamiento 12 kW~38 kW

Precisión del caudal ±0,2 L/min

Precisión de temperatura ±0,3℃

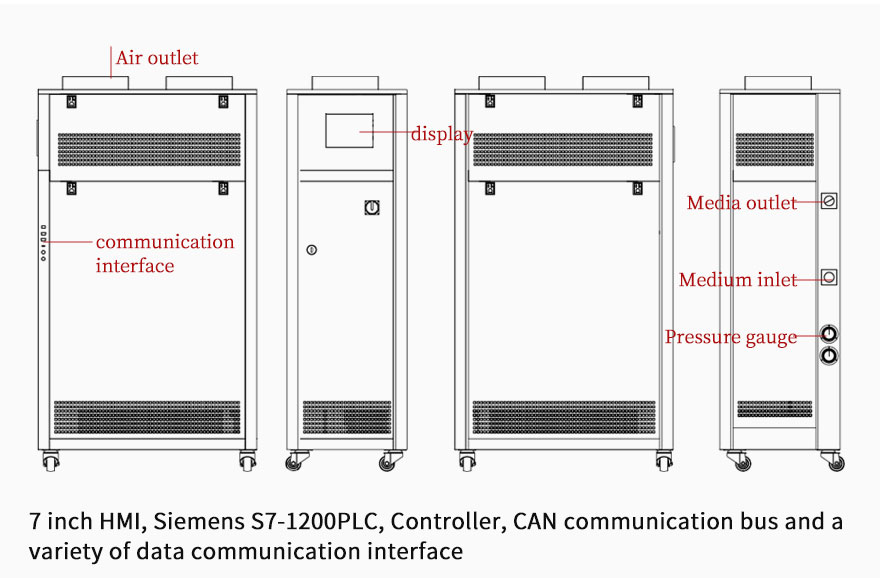

LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor