Importance of refrigerants in new energy vehicle battery test systems

If the flow rate of the refrigerant in the new energy vehicle battery test system is extremely small, the refrigerant will start to expand from the first expandable space at the rear end of the throttle valve. Most of the see-up of the rear end of the expansion valve is often due to lack of cooling. Or the expansion valve flow is not enough, too little refrigerant expansion will not use all the evaporator area, only the low temperature is formed locally in the evaporator, and some areas are rapidly expanded due to the small amount of refrigerant, causing the local temperature to be too low, and the evaporator appears. Frosting.

After local frosting, due to the formation of a thermal insulation layer on the surface of the evaporator, the heat exchange amount in the area is low, the expansion of the refrigerant is transferred to other areas, and the entire evaporator is frosted or frozen, and the entire evaporator is insulated. The layer, then the expansion spreads to the compressor return pipe causing the compressor to return to the air. Since the amount of refrigerant is too small, the evaporation pressure of the evaporator is low, resulting in low evaporation temperature, which will gradually lead to condensation of the evaporator to form a heat insulation layer and transfer the expansion point to the compressor return air to cause the compressor to return to the air. All of the above points will show the evaporator frosting before the compressor of the new energy vehicle battery test system returns to air.

If the new energy vehicle battery test system has a heat bypass valve, then just adjust the hot gas bypass valve. The specific method: open the rear end cover of the hot gas bypass valve, and then use the 8th hex wrench to turn the adjustment inside the clockwise Nut, the adjustment process should not be too fast, generally pause for about half a circle, let the system run for a period of time to see the frost condition and then decide whether to continue to adjust. After the operation is stable, the compressor frosting phenomenon disappears and the end cap is tightened. For models below 15 cubic meters, since there is no hot gas bypass valve, if the frosting phenomenon is serious, the take-off pressure of the pressure switch of the condensing fan can be appropriately adjusted.

Specific method: first find the pressure switch, remove the adjustment nut of the pressure switch to fix the small piece, and then use a Phillips screwdriver to rotate clockwise, the whole adjustment also needs to be carried out slowly, adjust a half circle to see the situation and then decide whether it needs adjustment.

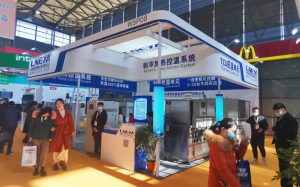

Therefore, the refrigerant in the new energy vehicle battery test system is very important. Secondly, the choice of refrigerant is also very important. The mixed refrigerants of professional manufacturers of production equipment have certain advantages in performance, so it is recommended that users choose according to their own needs.

Recomendaciones relacionadas

-

Efecto del separador de aceite en un frigorífico de temperatura ultrabaja

2054In ultra-low temperature chillers, oil separators are an important accessory. In most cryogenic refrigerators, there are oil separators. What are the effects of oil separators on cryogenic refrigerators? Needless to say, the position of the cryoge...

Ver detalles -

¿Cómo sustituir la válvula de cuatro vías de un equipo de refrigeración industrial?

1362La válvula de cuatro vías del equipo de refrigeración industrial necesita ser reemplazada a tiempo después de un largo período de uso, así que ¿cómo reemplazarla? Para sustituir el equipo de refrigeración industrial, primero debe retirar el tubo de conexión ...

Ver detalles -

-

Small desktop sealed chiller troubleshooting solution

1477Small desktop sealed chillers will have more or less failures after long-term use, so how can the compressor be solved if there are some faults? LNEYA specializes in the development and production of small desktop sealed chillers with a temperatur...

Ver detalles

LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor