Prueba del motor del vehículo eléctrico Instrucciones del enfriador del sistema de refrigeración

With the continuous development of new energy vehicles, Chiller, the electric motor motor test cooling system, is also developing. The new chiller for motor testing of new energy vehicles can adaptively adjust the chiller according to the dynamic heat change during motor and controller testing. Cooling capacity to meet the cooling requirements of the motor and its controller test.

In order to improve the working efficiency of the engine and reduce the fuel consumption rate, the heat dissipation of the engine can be adjusted according to the real-time working conditions, and the operating temperature of the engine is maintained at a high fuel efficiency temperature, and an electronically controlled cooling system of the automobile engine is designed. The chip is used as a controller to jointly control the cooling fan and the water pump in the cooling system, and the rotation speed of the cooling fan and the water pump is adjusted according to the operating temperature required by the engine in real time. The electronically controlled cooling system Chiller has a simple design and a simple structure, which solves the problems that the traditional engine can not adjust the working temperature and noise of the engine as needed.

The electric vehicle motor test cooling system Chiller is aimed at the water temperature control problem of the passenger car engine cooling system. The simulation model of a certain type of cooling system is established. The model is verified by the bench test. The control strategy of PI feedback control and feedforward-feedback integrated control is designed based on the model.

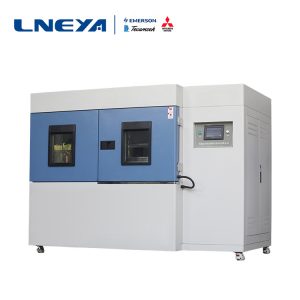

Electric vehicle motor test cooling system Chiller uses high-quality components to integrate technology in a designed way, so that the system can achieve matching results, and the unit performance is more and more. It adopts processing technology to manufacture and produce, and implements strict quality inspection standards. The system welding process uses nitrogen-filled protection welding, and the system is clean and free of debris. Electronically controlled cooling system Chiller control After years of research and development and practice, the unit realizes manual control, has fault self-diagnosis function, dynamically detects system load, maintains load dynamic matching, reserves remote control interface, and makes the operation interface humanized, simple and convenient.

How to choose Chiller for the electric vehicle motor test cooling system, first determine the cooling temperature range required for the refrigeration equipment supporting processing technology. According to the refrigerant medium, the type of chiller is generally divided into normal temperature type, low temperature type, medium low temperature type and ultra low temperature type. It is mainly judged according to the chiller cooling medium. Generally, the chiller is classified into water-cooled type and air-cooled type, which should be processed according to production. The needs of the process are selected. User selection needs to be selected according to its own working conditions, avoiding the selection error and making it unavailable.

Recomendaciones relacionadas

-

Influence of refrigeration factors on high temperature enclosed explosion-proof industrial chillers

1750Check whether the high and low temperature enclosed explosion-proof industrial chiller is the cause of its own failure. The selection must be accurate. If the model is not in place, the required refrigeration effect will also not be achieved. It i...

Ver detalles -

Instrucciones de estabilidad estructural para grandes congeladores industriales

1938En la industria actual se utilizan grandes frigoríficos industriales. Con el fin de mantener un funcionamiento sin problemas, la estructura relacionada también necesita mantener un estado estable con el fin de estabilizar y operar de manera eficiente. La estructura principal de Wuxi Guanya...

Ver detalles -

Precautions for chiller cooling system in low temperature operation test

1974There are certain differences in the use method, function, structure, etc. of different types of chiller cooling systems for low-temperature operation test. The chiller of the industrial low-temperature operation test requires heat to be generate...

Ver detalles -

Treatment of insufficient exhaust gas in high and low temperature impact test chamber compressor

1828The efficiency of the high and low temperature impact test chamber during use is very important. If there is a shortage of high compressor exhaust, we need our LNEYA technicians to solve it in time. So, how to solve it better? The high and low tem...

Ver detalles

LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor