How to Choose Chiller and Injection Moulding Machine?

A. First way:

The 1HP water-cooled chiller can be equipped with 80 tons locking force injection moulding machine, and the temperature can be controlled at 5-10 degrees.

The 1HP water-cooled chiller can be equipped with 100 tons mould-locking force injection machine, and the temperature can be controlled at 10-15 degrees.

The 1HP water-cooled chiller can be equipped with 120 tons mould-locking force injection moulding machine, and the temperature can be controlled at 15-20 degrees.

(The matching of air-cooled chiller is 0.8 times that of water-cooled chiller, that is, the temperature of injection moulding machine of 1HP air-cooled chiller with 64 tons of clamping force is controlled at 5-10 degrees.)

B. The second way:

1HP water-cooled chiller can be equipped with injection moulding machine with a single injection volume of 10 QZ, and the temperature can be controlled at 5-10 degrees.

Injection Mold Quantity 1QZ=28.5g

The above formulas are the results summarized by the classics. In addition to the above formulas, the salesman should filter the actual situation and select the appropriate chiller.

C. Matching of chillers and cooling towers:

According to experience, 1HP chiller needs a cooling tower of 1.2 tons to take away the heat generated by the chiller.

We are a top chiller manufacturer. Welcome to buy our products.

Recomendaciones relacionadas

-

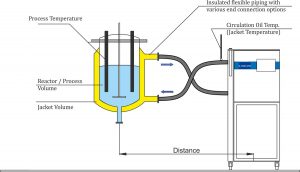

Puntos a los que prestar atención al elegir una máquina de control del ciclo de temperatura del reactor

1569La máquina de control de circulación de temperatura del reactor siempre ha sido un equipo indispensable para las empresas farmacéuticas y químicas. Como un equipo experimental de refrigeración y calefacción, si la temperatura del reactor comprado...

Ver detalles -

The cooling circulation system is used to collect the non-condensable tail gas in the distillation s

1602Most rectification towers are two-stage condensation. The first stage uses cooling water, mainly condensing the top steam, and the second stage uses chilled water or ethylene glycol, which is mainly used to treat tail gas and remove a small amount...

Ver detalles -

High precision semiconductor incubator maintenance instructions

1932The high-precision semiconductor incubator is in the state of the evaporator as a gas refrigerant; after the adiabatic shrinkage of the shrinking machine, it becomes a high-temperature and high-pressure state, and the contracted gas refrigerant is...

Ver detalles -

Ultra Low Temp Chiller Features

1676The ultra low temp chiller is controlled by microcomputer, and the refrigeration compressor and its system components are energy-saving products, which greatly improves the reliability of the whole machine. The unit can realize multi-stage energy ...

Ver detalles

LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor