Descripción medioambiental del condensador de un gran congelador industrial

En el procesamiento industrial del frío, los grandes congeladores industriales son uno de los equipos más utilizados. Entre ellos, el condensador es uno de los componentes principales, y su rendimiento es muy importante. Por lo tanto, al elegir, todo el mundo todavía tiene que entender.

Cuando el sistema de congelación industrial de gran tamaño está en funcionamiento, la razón del cambio de la temperatura de condensación es el cambio de la temperatura del medio refrigerante. La temperatura de condensación depende del área de transferencia de calor del condensador, de la temperatura del medio refrigerante, de la pureza y cantidad suficiente del refrigerante y del compresor. La temperatura y el desplazamiento del escape, etc. En funcionamiento normal, la temperatura y la presión de condensación son básicamente estables, y el espacio puede ajustarse. A menudo se debe a un fallo del sistema (como un corte repentino de agua o un número inadecuado de condensadores), que provoca el mal funcionamiento de la máquina. En funcionamiento, debe comprobarse con frecuencia y encontrarse. Cuando tenga un problema, debe encontrar la causa y solucionarlo a tiempo para evitar que la máquina sufra daños más graves.

La temperatura ambiente de los diferentes tipos de condensadores para grandes congeladores industriales es diferente. La temperatura de condensación de los condensadores verticales, horizontales de carcasa y de ducha es de 4 a 6 °C más alta que la del agua de refrigeración, y la condensación de los condensadores evaporativos La temperatura es de 5 a 10 ° C más alta que la temperatura de bulbo húmedo del aire exterior en verano, y la temperatura del condensador refrigerado por aire es de 8 a 12 ° C más alta que la temperatura del aire.

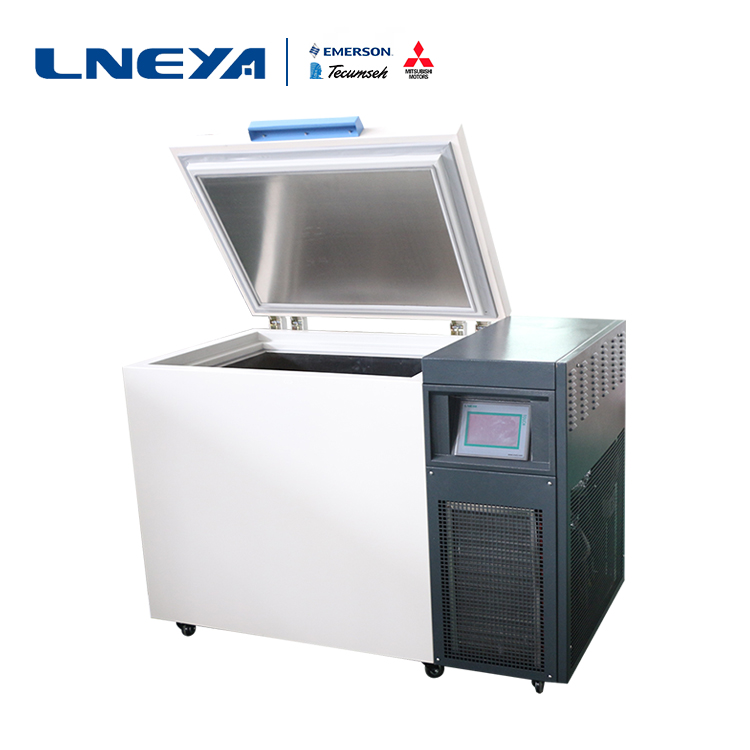

En el sistema de refrigeración del congelador industrial grande Wuxi Guanya LNEYA, la liberación de calor externo del refrigerante es el funcionamiento normal del condensador. Después de que el gas a alta temperatura descargado por el compresor entra en el condensador, el calor se transfiere al medio (agua o aire), el refrigerante. El vapor se enfría y se condensa en un líquido, y el refrigerante licuado entra en el evaporador a través de la estrangulación, logrando así el propósito de la refrigeración de ciclo repetido del refrigerador industrial a prueba de explosiones a gran escala. Si el acumulador y el condensador se instalan en el gran congelador industrial a la misma altura, el tubo de salida en la parte inferior del condensador debe doblarse hacia arriba hasta la parte superior del acumulador. Esto puede provocar la aparición de la junta líquida en la tubería. La función de escape del compresor, una vez que hay un cierto nivel de líquido en el acumulador, reducirá el área de condensación del condensador, aumentará la temperatura y la presión de condensación, aumentará el consumo de energía, y hará que las condiciones de funcionamiento del sistema de refrigeración del congelador sean malas.

El condensador y el acumulador en el gran congelador industrial son uno de los accesorios más importantes. El conocimiento de los accesorios anteriores espera que todo el mundo puede entender con claridad.

Recomendaciones relacionadas

-

Maintenance knowledge of high and low temperature constant temperature circulation device

1994The high and low temperature constant temperature circulation device is one of the more common equipments in the temperature control system. A good equipment is inseparable from daily maintenance. So how much do you know about maintenance? High an...

Ver detalles -

What are the main hazards of the reaction kettle in the reactor intelligent temperature control syst

1779The intelligent temperature control system of the reactor is used in various chemical fines. With the constant attention of the industry safety issues, some risk factors of the intelligent temperature control system of the reactor should be avoide...

Ver detalles -

¿Cómo elegir un refrigerador láser?

2019The term laser is an acronym for light amplification by stimulated radiation. When the electrons in the atoms of optical materials (such as glass, crystal or gas) absorb the energy of the current, a laser is generated. The increased energy excite...

Ver detalles -

Explanation Protection for Air Cooled Precision Chiller

1657The places where need air-cooled precision chiller indicate they have high demanding for operating accuracy. Therefore, the protection settings have to work out. Then, which kind of protection for air-cooled precision chiller should be done?Discha...

Ver detalles

LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor