How To Reduce Operating Costs For Electric Vehicle Power Battery Testing Equipment?

Since many harsh environments easily affect the operating power of electric vehicle power battery testing equipment, in order to ensure the safety of equipment operation, enterprises need to choose a suitable safety environment when installing electric vehicle power battery testing equipment. The installation environment is good, and regular maintenance can extend the life of the electric vehicle power battery testing equipment, and provide conditions for reducing the cost of using the electric vehicle power battery testing equipment.

After completing the compressor maintenance task, the company is required to carefully check the condenser and evaporator. Usually, there is a fault in the condenser and the evaporator, which may cause the performance of the cooling test of the electric vehicle power battery detection device to be poor, which cannot meet the needs of the enterprise for the low temperature environment. If a large amount of energy is consumed, the electric vehicle power battery testing equipment of Wuxi Guanya(LNEYA)Constant Temperature Refrigeration Technology Co., Ltd. still cannot quickly reduce the ambient temperature. Therefore, the operating efficiency of the electric vehicle power battery testing equipment is low, and the condenser and the evaporator need to be repaired in time. In order to get a better cooling effect.

When the electric vehicle power battery testing equipment is regularly maintained, it is necessary to conduct comprehensive testing and maintenance on the compressor. Since the compressor belongs to the core component of the electric vehicle power battery testing equipment, if there is a fault, the equipment will not operate normally. Maintenance of electric vehicle power battery testing equipment requires the failure detection and elimination of the compressor as the main test content, which can ensure the stability of the compressor operation, improve the running performance of the compressor, and achieve the goal of rapidly reducing the ambient temperature.

Because the electric vehicle power battery testing equipment is widely used in the testing of new energy batteries, the necessary maintenance can reduce the operating cost of the electric vehicle power battery testing equipment and improve the operating efficiency of the electric vehicle power battery testing equipment.

Recomendaciones relacionadas

-

The cooling circulation system is used to collect the non-condensable tail gas in the distillation s

1605Most rectification towers are two-stage condensation. The first stage uses cooling water, mainly condensing the top steam, and the second stage uses chilled water or ethylene glycol, which is mainly used to treat tail gas and remove a small amount...

Ver detalles -

How to Choose Water Chiller Units in Small Factories

1837Professional water chiller factory said that the quality of equipment can be seen from the three main components of small water chiller units. The most important one is the compressor, which is the heart of the unit and the most critical component...

Ver detalles -

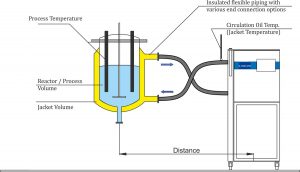

How to choose the cooling and heating temperature control system?

1762The price of the refrigeration heating temperature control system is not the main factor. The main purpose is to implement the temperature control technology through the temperature control function. However, it is not the temperature control syst...

Ver detalles -

¿Cómo elegir la enfriadora para refrigerar el tanque de mezcla?

1952Los tanques de mezcla se utilizan en revestimientos, medicina, materiales de construcción, productos químicos, pigmentos, resinas, alimentos, investigación científica y otras industrias para remover, mezclar, combinar y homogeneizar materiales. El tanque de mezcla genera calor durante el proceso...

Ver detalles

LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor