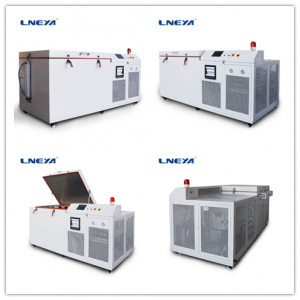

LNEYA Liquid High-Low Temp. Test Chamber

High and low temperature impact chamber is a necessary test equipment of material such as metal, plastic, rubber, electronics and so on, used for testing material structure or composite material. It can figure out the tolerance degree in the instantaneous continuous environment of extremely high temperature and extremely low temperature to know the chemical change or physical injury because of contraction principle at least time. It is divided into two sides and three sides. The difference lies between the test mode and the internal structure. The product meets the requirements of GB/T2423.1-2008 TESTA, GB/T2423.2-2008 TEST B, GB-T10592-2008, GJB150.3-198, GJB360A-96 METHOD 107.

The liquid impact test box (also called liquid tank impact test box) adopts stirring convection liquid medium instead of circulating air medium for heat transfer, which can meet the rigorous test requirements. The system structure can be divided into high temperature liquid tanks (preheating zones). The cryogenic liquid bath (precooling zone) consists of two parts, which are controlled by mechanical transmission components to alternately place test samples into high and low temperature baths to simulate the transient environment between high and low temperatures.

The liquid impact test chamber is suitable for the simulation evaluation of the reliability of the aviation industry, defense industry, automation components, auto parts, electronic and electrical instrument components, semi-conductor and other related products and materials under conditions of rapid changes in ambient temperature to determine the reliability of the product. Whether the parameters such as sex and stability can be qualified or not, the test provides the basis for predicting and improving the quality and reliability of the product.

Performance characteristics:

1. Forced stirring convection is used in high and low temperature liquid tanks.

2. The automatic upper, lower, left, and right displacement mechanism is used to move the sample basket to the preheating and pre-cooling tanks, and the way of the round-trip impact.

3. Use a single identical liquid in the high and low temperature tank to reduce the cost of frequently changing liquids.

4 using the original LCD integrated Chinese and English color LCD touch screen controller

5. The equipment can meet the needs of the site and can choose water cooling or air cooling

6. The thermal shock mechanism movement time is within 10 seconds

Recomendaciones relacionadas

-

Guidelines for Safe Use and Maintenance of Ultra-Low Temperature Freezer

15411. It is necessary to understand the influence of environment on refrigerators.2. Familiar with basic operation, maintenance and maintenance knowledge3. Develop good habitsLet the refrigerator breathe freely;Let the air around the refrigerator ci...

Ver detalles -

Description of LNEYA industrial ultra-low temperature freezer

1854LNEYA industrial ultra-low temperature freezer is mainly used in industrial cold treatment to precipitate uniform, fine and dispersed carbides on the metal structure matrix. The appearance of such a carbide will bring about a significant increase ...

Ver detalles -

Solutions to high-pressure failures of deep-circulation chillers

1548Deep-circulation chillers are process cold sources used in the production and processing of chemical and pharmaceutical intermediates, petrochemicals, machinery, medicine, electronics, new materials, aerospace, optoelectronic technology, and new e...

Ver detalles -

¿Cuáles son los refrigerantes del congelador de temperatura ultrabaja de 120 grados?

2087Los refrigerantes de los diferentes fabricantes de congeladores de ultra baja temperatura son diferentes. Los refrigerantes comúnmente utilizados en los equipos de refrigeración LNEYA son R404, R22, etc. Entonces, ¿cuál es la diferencia entre los dos?

Ver detalles

LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor