Maintenance method of minus 17 ° C ultra-low temperature refrigerator

After the long-term use of the ultra-low temperature refrigerator of minus 17 °C, it is necessary to carry out certain maintenance work. If the user does not know how to carry out the maintenance work, you can contact the manufacturer to obtain the relevant maintenance methods.

The sub-17°C ultra-low temperature refrigerator compressor unit must change the refrigerating oil once a year, or decide whether to change the oil in advance according to the actual situation or the analysis of the oil product. Replace the oil filter when the oil pressure drops by 30% or the unit is running for half a year. Also check the presence of metal shavings in the filter to confirm the internal wear of the unit. Check and tighten the pipe connection of the spool and check the solenoid valve coil of the spool. Also check the insulation of the motor, add grease or lubricant to the motor bearings, check the contacts of the motor starter, and check the contactors of the motor starter.

The zero-low temperature system of the ultra-low temperature refrigerator of 17 °C needs to replace the drying filter of the oil returning system in time, clean the nozzle of the oil ejector, clean the accumulation in the sedimentation elbow, check the solenoid valve of the ejector loop to operate normally, and check the entire oil return. The connection line of the system is unobstructed.

The evaporator and condenser of the ultra-low temperature refrigerator with a temperature of minus 17 °C should check the water flow of the chilled water and the cooling water, check the water flow switch of the chilled water and the cooling water, check the charge of the refrigerant, check the water chamber and the end cover of the evaporator and the condenser. Screws. Confirm that there is no water leakage.

The cryogenic refrigerator with a temperature of minus 17 °C needs to check the refrigerant charge. After the unit is stopped, the refrigerant charge should be checked and adjusted. After the compressor and pump are shut down for four hours or more, the condenser and evaporation are performed. The pressure and temperature of the device are balanced. At this point, the refrigerant level should be visible from the sight glass and the refrigerant level should be recorded. And according to the original record, judge the sealing condition of the unit.

The maintenance method is as shown above. It is recommended that the user do the maintenance work, which is more conducive to the operation of the ultra-low temperature refrigerator with a temperature of minus 17 °C.

Recomendaciones relacionadas

-

Practical application of different compressors in the industrial chiller industry

1464In the current refrigeration industry, the efficiency of the equipment is closely related to temperature. LNEYA tells you that the efficiency of the refrigeration equipment required under control has been improved. Then, the selection of the compr...

Ver detalles -

Los equipos profesionales de alta calidad ayudan al laboratorio a producir resultados sin fin

2881In recent years, China's economy has continued to grow. Under the development opportunity of professional high and low temperature integrated machines, laboratory scientific and technological achievements are also in sustainable development. LNEYA...

Ver detalles -

What is the connection between temperature and chemical reaction?

1395The chemical reaction can produce more stable products, and then as the temperature is released, the energy before the component reaction is released. On the other hand, the components of the reaction may produce different products, depending on t...

Ver detalles -

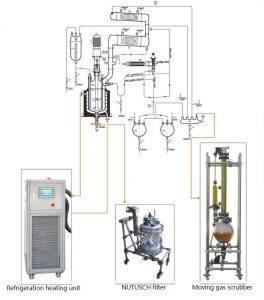

Aplicación del circulador de refrigeración y calefacción del reactor enchaquetado en las reacciones químicas

1716aplicación del sistema de refrigeración y calefacción del reactor enchaquetado

Ver detalles

LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor