Puntos de mantenimiento rutinario de unidades de refrigeración especiales para instrumentos de laboratorio

Industrial refrigeration units dedicated to laboratory instruments are used more in the pharmaceutical and chemical industries, and care must be taken when using them.

The daily maintenance of the industrial refrigeration unit dedicated to experimental instruments is mainly reflected in the following aspects:

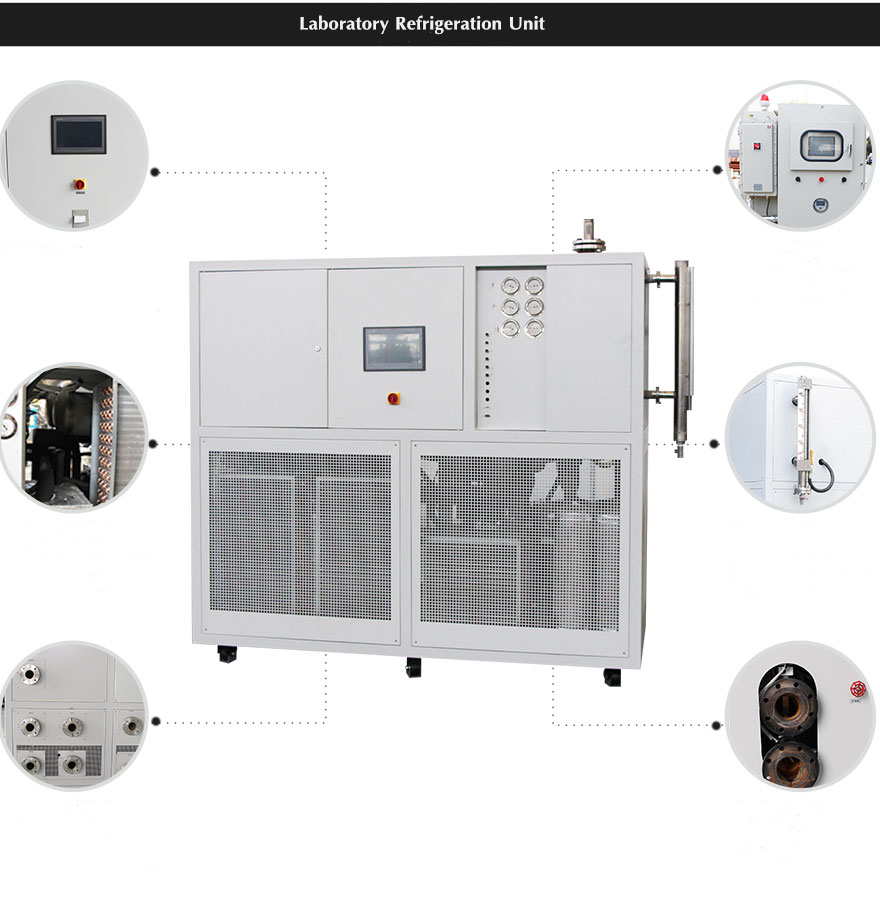

1. Condenser

The high-temperature and high-pressure Freon of the refrigeration system of the industrial refrigeration unit dedicated to the experimental instrument comes out of the compressor and enters the condenser, releasing a large amount of heat to the cooling medium and being liquefied by the cooling.

If the industrial refrigeration unit dedicated for laboratory instruments has been used for more than half a year, or the high and low pressure engines frequently fail, or the cooling capacity is reduced, please arrange a technician to clean the condenser. The fin condenser is generally cleaned with a high-pressure water gun. Be careful not to clean it sideways, which can easily cause the fin to fall over. Shell-and-tube condensers are generally immersed and circulated with descaling chemicals, and then the end cover is opened, and the pipes are cleaned one by one with a gun gun. Cleaning the condenser can significantly improve the refrigeration efficiency of the industrial refrigeration unit dedicated to laboratory instruments.

2. Compressor

Every time the compressor operating time of the industrial refrigeration unit dedicated to the experimental instrument exceeds one thousand hours, all details of the compression equipment should be checked. For example: whether the lubricating oil is normal; whether the running current of the compressor is normal; whether there is any abnormality when the compressor is running. Of course, the current refrigeration technology is quite mature, there are many sensors and protectors. When the unit alarms the fault, it should be repaired according to the fault location. When the compressor makes abnormal noise when it is running, it should be shut down for maintenance, mostly due to insufficient lubricant.

3. Refrigerant

The industrial refrigeration unit dedicated to experimental instruments is an indispensable equipment for industrial production now, and each unit is inseparable from the participation of refrigerant, so the lack of refrigerant will affect the normal operation of the machine and will appear The cooling capacity of the industrial refrigeration unit dedicated to the experimental instrument is insufficient, or the cooling temperature is very slow.

Routine maintenance cannot be ignored. Effective maintenance can keep the industrial refrigeration unit dedicated to laboratory instruments in an effective state of operation.

Recomendaciones relacionadas

-

Aplicación y ventajas de los equipos de prueba de motores de automoción de nueva energía

1577LNEYA's new energy motor test equipment is used in HEV (Hybrid Electric Vehicle), BEV (Electric Vehicle), Hydrogen Power Vehicle, Fuel Cell Electric Vehicle, EREV (Extended Range Electric Vehicle) and other new energy vehicles. LNEYA's equipment a...

Ver detalles -

Where do you need low temperature chiller and introduction

1444Even though water is one of the most precious and scarce resources, it is still used as a coolant in many laboratories. Unfortunately, most of the water used as a coolant is not recycled, resulting in higher and higher laboratory costs and wasted ...

Ver detalles -

Typical application of refrigeration heating temperature control system

1388LNEYA Dynamic thermostatic control of cold and heat source of high pressure reaction kettle, dynamic thermostatic control of double layer glass reaction kettle, and dynamic thermostatic control of cold and hot source of double-layer reactor. Micro...

Ver detalles -

¿Cómo elegir el modelo del dispositivo de control de temperatura de la máquina de litografía?

1461¿Cómo elegir un refrigerador industrial adecuado y a qué aspectos hay que prestar atención en el diseño de la unidad?1. Elija un dispositivo de control de temperatura refrigerado por aire o por agua para la máquina litográficaLos métodos de condensación de los...

Ver detalles

LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor