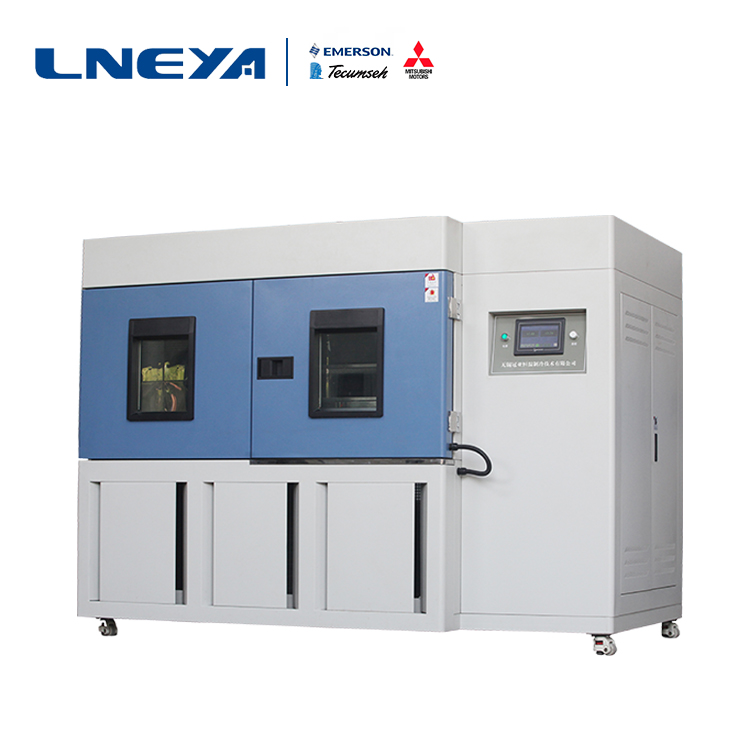

Aceite de refrigeración para cajas de impacto en frío y caliente de material de ultra alta temperatura

The ultra-high temperature material impact test chamber test device has too much frozen oil in the evaporator, which can also cause insufficient cooling and cause slow cooling. The oil stored in the evaporator of the ultra-high temperature material impact test chamber test device can be directly judged by the hot and cold boundary line of the oil surface. If the oil level is too high, it should be released in time.

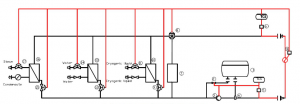

Some Freon and refrigerating machine oil dissolve each other. Therefore, when the refrigerant in the refrigeration system of the ultra-high temperature material impact test chamber test device is circulating, it is inevitable that the refrigerating machine oil will remain in the various components, and the residual oil in the heat exchanger will affect Heat transfer coefficient. Especially when the refrigerating machine oil enters the evaporator of the test device, if the structural design or installation is unreasonable, the ultra-high temperature material impact test device will only enter or reduce the refrigerating machine oil, so that the residual refrigerating machine oil in the evaporator is more The more you come, the more serious the heat absorption effect, and the lack of cooling capacity. If you don’t handle it at this point, the temperature will not drop. Therefore, you must carry out the oil draining work.

How to judge that the ultra-high temperature material impact test chamber test device has more refrigeration oil in the evaporation tube and affects the refrigeration is a difficult thing. In the case of the ultra-high temperature material impact test device, there is a significant anomaly, that is, the hoarfrost on the evaporation tube is sparsely pulled, incompletely formed, and is defrosted, if there is no other fault, then It is likely that there is too much residual refrigeration oil in the evaporator tube. To remove the freezer oil in the evaporator of the ultra-high temperature material impact test chamber test device, it must be removed, purged and dried. For the tube type evaporator, it is inconvenient to disassemble, the inlet of the test device evaporator can be blown with compressed air, and then the tube is baked with a blowtorch.

There are also many types of evaporators for the ultra-high temperature material impact test chamber test device. Once there are more refrigeration oils, we need to solve them in time.

Recomendaciones relacionadas

-

Chemical synthesis process control system temperature control system TCU

1795Today, let's talk about our DCS integrated control system (temperature and other control of synthetic process). Scalability: the system is an open system, which provides standard TCP / P data communication interface protocol, interface software an...

Ver detalles -

Analysis of the causes of noise generated by the operation of low temperature chillers

1591Noise is common in the operation of industrial equipment. There are many reasons for noise, which may be caused by some environmental problems in the installation. When noise is generated, we must first confirm the cause and whether it is an inter...

Ver detalles -

Precautions for the use of LNEYA chillers in industrial processes

18011. Installation (check the machine for damage, choose the right location for installation and maintenance) 2. The location of the installation unit must be the floor, mounting mat or foundation, the level is within 6.4mm, and can withstand the wor...

Ver detalles -

What are the effects of oil level and oil difference in low temperature chillers?

1881LNEYA tells you that in addition to the refrigeration system, the lubricating oil system is also an important part, with its own oil storage and special oil cooler. Oil level It refers to the level of the lubricant in the oil storage container. Th...

Ver detalles

LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor