Qué hacer si el equipo de la cámara de pruebas de choque térmico no alcanza la temperatura fijada

The choice of the manufacturer of the thermal shock test chamber is related to the quality of the thermal shock test chamber. Once the quality is set, the temperature setting of the equipment will not be closed. What should I do if I encounter the temperature setting problem?

The temperature set by the thermal shock test chamber is not up to the possibility that the heat exchange humidification tube is broken. You can either repair the factory or replace the new thermal shock test chamber directly. In the high temperature test, if the temperature does not change. When testing the temperature value, the electrical system can be inspected to eliminate the fault one by one, or the temperature probe may be broken, causing the device to not work when the water temperature is lower than the set standard temperature or 37 degrees.

The temperature and temperature of the thermal shock test chamber is too long or the heating tube is aging and damaged. When the actual water temperature is far below 37 degrees, the equipment has not worked, or the work is not working. If the temperature rises directly to cause over-temperature protection, the controller fails and the control instrument must be replaced. If the temperature is too high, you need to set the PID setting parameters first.

If the temperature rises very slowly, it is necessary to check the air circulation system to see if the regulating baffle of the air circulation is normally turned on. If the temperature of the thermal shock test box rises very quickly, check whether the motor of the air circulation is running normally. Because there is a time limit for use, so the running time is too long, it is inevitable that there will be some kinds of various faults, usually pay attention to regular maintenance and maintenance, generally can be largely avoided. If you encounter a large technical problem, you should seek solutions in time with the manufacturer.

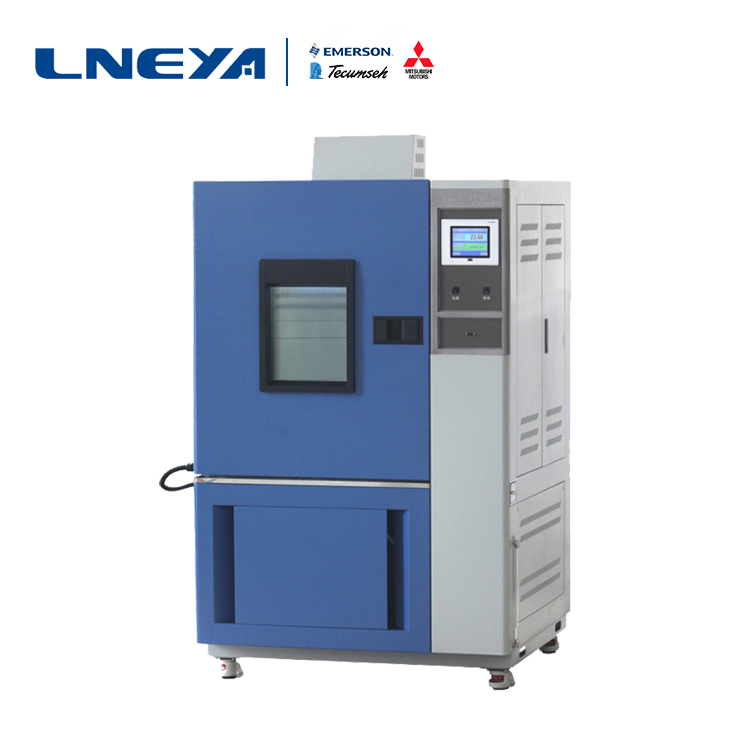

LNEYA thermal shock test box manufacturer is a professional hot and cold impact test box manufacturer integrating R&D, production and sales. It has more than ten years of experience in refrigeration and heating equipment production, and has reached cooperation with many domestic enterprises.

Recomendaciones relacionadas

-

High-power industrial refrigerator evaporator maintenance precautions

1762High-power industrial refrigerators are used in industrial cold processing. Evaporators in high-power industrial refrigerators are one of the most important components and one of the factors affecting the cooling effect of high-power industrial re...

Ver detalles -

Funcionamiento eficaz de la máquina integrada de alta y baja temperatura

1835Para garantizar un funcionamiento más eficaz de la máquina integrada de alta y baja temperatura, debe seleccionar el tipo de equipo adecuado y resolver el problema a tiempo. La selección de máquinas integradas de alta y baja temperatura requiere unos p...

Ver detalles -

Varios aspectos de atención del ultracongelador

1799El rendimiento del congelador de ultra baja temperatura se reducirá naturalmente debido a la aplicación de largo período en todos los campos. Por lo tanto, Guanya Refrigeration Technology Co., Ltd, líder en fabricantes de congeladores de temperatura ultra baja tiene que recordar a todos los usuarios...

Ver detalles -

Maintenance knowledge of high and low temperature constant temperature circulation device

1993The high and low temperature constant temperature circulation device is one of the more common equipments in the temperature control system. A good equipment is inseparable from daily maintenance. So how much do you know about maintenance? High an...

Ver detalles

LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor