Thermal Chillers for Semiconductor ATE & Process

Advanced liquid temperature control technology, actively exploring and researching component test systems, mainly used for temperature test simulation in pharmaceutical chemicals, new energy, semiconductors, and aerospace testing, with wide temperature direction and high temperature rise and fall, temperature range: -80°C~+90°C, temperature control accuracy up to: ±0.05℃, suitable for various test requirements.

Aplicaciones

Temperature control system for production process and testing links.

Applied in semiconductors, LEDs, LCDs, solar photovoltaics and other fields;

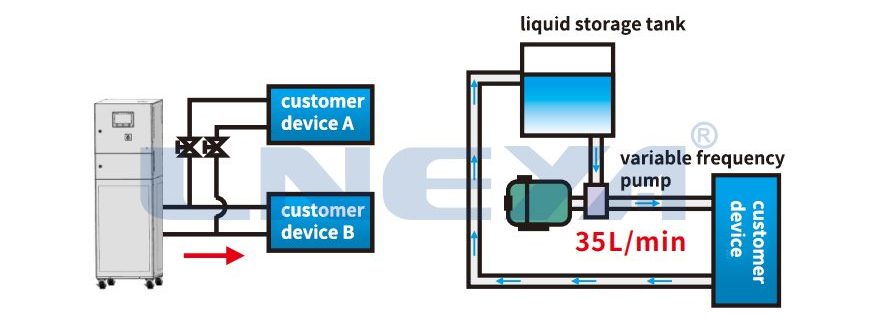

The variable frequency pump can adjust the circulating fluid pressure and flow, Circulation heating can be achieved without a heater;

Multi-channel independent temperature control, no mutual influence.

Such as chillers that control the processing temperature on the Fab equipments.

Cooling of CMOS/CCD sensors in semiconductor metrology systems.

Recirculating Chiller for semiconductor metering AOI system.

Refrigerador de un canal refrigerado por aire, diseñado principalmente para máquinas de grabado. Se utiliza para proporcionar un control independiente de la temperatura de las paredes laterales de la cámara.

Used for plasma bevel etch and deposition; Thermal Atomic Layer Etching of Metal Tungsten.

Serie de conversión de frecuencia FLTZ

Temperature control range: -45℃~+90℃

The chiller’s exhaust and suction temperature (pressure), condensing temperature, cooling water temperature (pressure), inlet and outlet liquid (gas) temperature (pressure), power consumption, current of each component, voltage, water tank level and other important information are all connected to the control system through sensors for comprehensive management, monitoring and recording.

| Modelo |

5℃~90℃ |

-25℃~90℃ |

-45℃~90℃ |

-80℃~+90℃ |

-100℃~+90℃ |

| Precisión del control de temperatura |

±0.05℃ |

±0.05℃ |

±0.05℃ |

±0.05℃ |

±0.05℃ |

| Capacidad de enfriamiento |

6KW~40KW @10℃ |

2KW~15KW @-15℃ |

1KW~8KW @-35℃ |

0.6KW~3KW @-70℃ |

1.5KW~3KW @-90℃ |

Rated test conditions for all equipment: Dry bulb temperature: 20℃; Wet bulb temperature: 16℃. Inlet water temperature: 20℃; Outlet water temperature: 25℃.

FLTZ Frequency Conversion Multi-channel Series

Temperature control range: -45℃~+100℃

Multi channel independent temperature control, which can have a separate temperature range, cooling and heating capacity, thermal conductivity medium flow rate, etc., adopts two independent systems.

The system can be used for universal expansion tanks, condensers, cooling water systems, etc., which can effectively reduce equipment size and operation steps.

| Modelo |

FLTZ-203W/2T sistema dual |

FLTZ-305W/2T sistema dual |

FLTZ-406W/2T sistema dual |

| Rango de temperatura |

-20℃~90℃ |

-30℃~90℃ |

-45℃~90℃ |

| Precisión del control de temperatura |

±0.1℃ |

| Caudal del medio conductor de calor |

15~45l/min 6bar max |

| Capacidad de calefacción |

2,5 kW |

2,5 kW |

2,5 kW |

2,5 kW |

3,5 kW |

3,5 kW |

| Capacidad de enfriamiento |

3kW @-15℃ |

3kW @-15℃ |

5kW @-15℃ |

5kW @-15℃ |

2.5kW @-35℃ |

2.5kW @-35℃ |

Rated test conditions for all equipment: dry bulb temperature: 20℃; wet bulb temperature: 16℃. Inlet water temperature: 20℃; outlet water temperature: 25℃.

ETCU Heat Exchange Chiller Series

Adopting compressor-free refrigeration system

temperature control range is: 5℃~+90℃

temperature control accuracy: ±0.05℃

| Modelo |

ETCU-005W |

ETCU-015W |

ETCU-030W |

ETCU-050W |

ETCU-100W |

ETCU-200W |

ETCU-300W |

| Rango de temperatura |

Cooling water temperature +5℃~90℃ |

| Precisión del control de temperatura |

±0.05℃(Temperatura de salida en estado estable) |

| Temperatura del agua de refrigeración |

7℃~30℃ Cooling water flow is controlled by Siemens/Honeywell regulating valves |

| Capacidad de enfriamiento |

5kW |

15 kW |

30 kW |

50 kW |

100 kW |

200 kW |

300 kW |

Rated test conditions for all equipment: dry bulb temperature: 20℃; wet bulb temperature: 16℃. Inlet water temperature: 20℃; outlet water temperature: 25℃.

AES Series Thermal Stream

Thermal Solutions for ATE testing

temperature control range is: -115℃~225℃

temperature control accuracy: ±0.1℃

| Modelo |

AES-4535

AES-4535W |

AES-6035

AES-6035W |

AES-8035

AES-8035W |

AES-A1035W |

AES-A1235W |

| Rango de temperatura |

-40℃~225℃ |

-60℃~225℃ |

-80℃~225℃ |

-100℃~225℃ |

-120℃~225℃ |

| Precisión de la temperatura |

±0.05℃(Temperatura de salida en estado estable) |

| Requisitos de aire |

Air filter < 5um air oil content < 0.1um air temp and humidity:5℃-32℃ 0-50%RH |

| Capacidad de tratamiento de aire |

10m³/h-m³/h pressure 5bar-7.6bar |

Contact LNEYA technical engineer for model selection

enfriadores que controlan la temperatura de procesamiento en los equipos Fab

advantages

- Resultados de estabilidad y repetibilidad de la producción eficientes;

- Utilización de intercambiadores de calor de placas y calentadores de tuberías para mejorar los índices de refrigeración y calefacción;

- Rango de temperatura muy amplio, sin necesidad de sustituir el medio líquido;

- Sistema totalmente cerrado que prolonga la vida útil de los líquidos conductores térmicos;

- Adoptando la bomba de accionamiento magnético, no hay problema de fugas del sello del eje;

- High temperature cooling technology, directly start the compressor to cool down at 300 ℃.

La bomba de frecuencia variable puede ajustar la presión hidráulica de circulación y el caudal

Heating function

Due to the use of heat generated during heating, circulating heating can be achieved without the need for a heater.

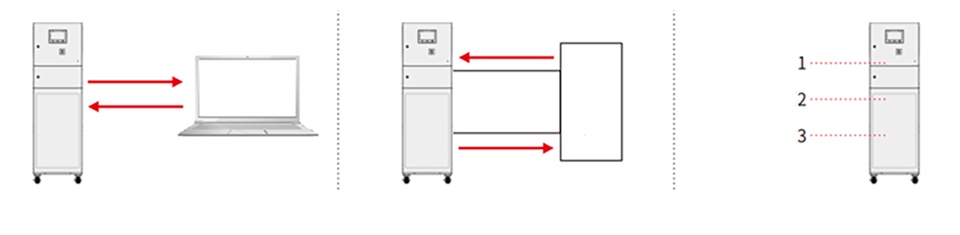

Función de comunicación

El equipo estándar incluye comunicación serial (RS232C, RS485) y entrada/salida de contacto. Puede comunicarse con dispositivos del cliente o sistemas de construcción.

client output signal

Customized Chiller Solutions

Productos recomendados

Temperature Control :-120℃~350℃

Temperature control for high pressure reactor;Double-layer glass reactor;Double-layer reactor;Microchannel Reactor;Distillation system;Material aging test;Vacuum chamber etc.

Temperature Control: -40℃~100℃

Simulación de temperatura para pruebas de calidad de vehículos: prueba de duración de la batería, banco de pruebas de inyectores/motores de combustible, prueba de airbags, banco de pruebas de componentes, etc. Puede simular las condiciones ambientales externas en la cámara climática o sustituir el sistema interno, lo que puede crear las condiciones de temperatura reales necesarias para el banco de pruebas.

Temperature Control: -85℃~250℃

Suitable for semiconductor process wet washing, photolithography, etching, chemical meteorological deposition, physical meteorological deposition, and the electronics industry (photolithography process)

Accept Customized Outdoor Chiller and Indoor Chiller

rovide 7 * 24 free consultation & comprehensive solutions

LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor