What are the applications of Industrial temperature control machine chillers?

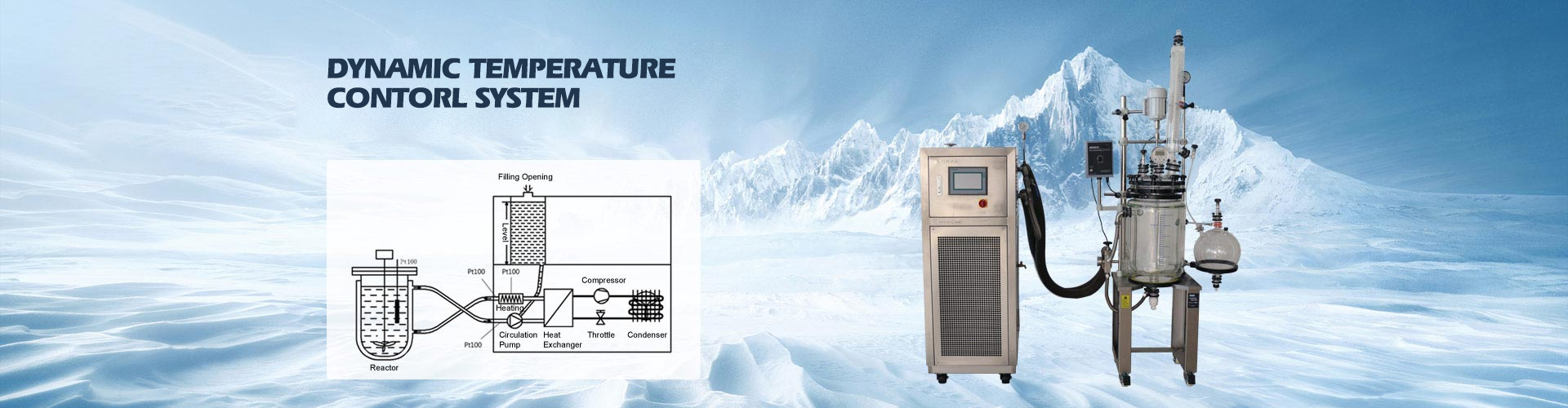

Industrial temperature control machine chillers are divided into oil-cooled and water-cooled according to the temperature and medium. The medium used is different for different temperatures, water can be selected for normal temperature, heat transfer oil for high temperature, and refrigerant for low temperature. According to the different cooling methods, it can be divided into air cooling and water cooling. Consider the ambient temperature of the industrial temperature control machine chiller, which affects the efficiency of the operation. If the temperature is higher, the effect of water cooling will be better; if the temperature is low, it is easy to freeze in winter, which has a great impact on the fluidity of water, so you can choose air cooling.

The two types of machines have certain requirements on the site. The water-cooled type requires water in the working environment, and uses water flow to exchange heat for cooling. If there is no water, it will not be able to work; the air-cooled type uses a fan to generate heat convection with the airflow outside the machine. . Good ventilation is required.

Industrial temperature control machine chillers can be used in multiple temperature test scenarios, such as in semiconductor production and testing of electronic devices, processes that require precise temperature control abound.

This includes, for example, the production of metal-organic compounds in the coating process of chemical vapor deposition for the production of LED wafers.

Two: The temperature control requirements of the new energy automobile industry are generally in the test bench and material testing links. All automotive components are subject to extreme temperature fluctuations.

Three: aviation heat sink experiment, component environment simulation test, evaporative cooling environment simulation test. Temperature simulation and temperature testing of materials are very important components in the aerospace field. Cyclic temperature change stress tests ensure that the components used do not have any failures, even under the extreme fluctuations of external conditions in space.

Recomendaciones relacionadas

-

enfriadoras hidráulicas enfriadoras industriales/de laboratorio?

807Los refrigeradores hidráulicos no son directamente equivalentes a los refrigeradores industriales o de laboratorio, pero tienen cierta relevancia y coinciden en su función. Todos ellos son dispositivos utilizados para proporcionar efectos de refrigeración. La principal diferencia radica en la ap...

Ver detalles -

Attention points for the use of rapid thermal cycle test airflow machine

1025The rapid thermal cycling test is a test equipment used in the metal, plastic, rubber, electronic and other material industries. It is used to test the material structure or composite material. It can be tolerated in a continuous environment of hi...

Ver detalles -

Características y aplicaciones de las enfriadoras de glicol

1115El enfriador de glicol se aplica al proceso de enfriamiento de máquinas rectificadoras, máquinas herramienta CNC y varias máquinas herramienta de precisión, que pueden reducir eficazmente la deformación térmica de las máquinas herramienta, mejorar la precisión de mecanizado de las máquinas herramienta y...

Ver detalles -

Necessity Of New Energy Electric Vehicle Battery Test System

882The battery performance of new energy vehicles directly determines the experience of new energy vehicle end users. The electric vehicle battery test system needs to test the performance reliability of new energy vehicle batteries. With the develop...

Ver detalles

LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor