Precautions for installation of special chiller for new energy testing

The installation of the special chiller for new energy testing is an important link before operation. The quality of the installation is directly related to the operation and operation status of the special chiller for new energy testing. So, what should be paid attention to in the installation of the special chiller for new energy testing?

If the special chiller for new energy test adopts semi-hermetic or fully-hermetic compressor, an oil separator should be installed, and an appropriate amount of oil should be added to the installed oil separator. When the evaporation temperature is lower than -15 degrees, a gas-liquid should be installed. Separator and add appropriate amount of refrigeration oil. Secondly, the compressor base should be installed with a shock-absorbing rubber seat, and the installation of the special chiller for new energy testing should leave a maintenance space to facilitate the observation of the adjustment of instruments and valves.

The high pressure gauge of the special chiller for new energy testing should be installed at the tee of the liquid storage and filling valve. The overall layout of the special chiller for new energy testing is reasonable and the color is the same. The installation structure of each type of unit should be consistent.

When debugging the special chiller for new energy test, it is necessary to pay attention to measuring the power supply voltage, measuring the resistance value of the three windings of the compressor and the insulation of the motor, checking the opening and closing of each valve of the refrigeration system, and pouring the refrigerant into the storage liquid to the standard charge after evacuation. 70%-80% of the filling volume, and then run the compressor, add air from low pressure to enough volume.

After the special chiller for new energy test is turned on, first listen to whether the sound of the compressor is normal, check whether the condenser and air cooler are running normally, and whether the three-phase current of the compressor is stable. After the special chiller for new energy test cools down smoothly, check the exhaust pressure, suction pressure, exhaust temperature, suction temperature, motor temperature, crankcase temperature, and expansion valve temperature in the refrigeration system, and observe the frosting of the evaporator and expansion valve. , observe the oil level and color change of the oil glass. Check whether the sound of the special chiller for new energy testing is abnormal.

Another point is that the special chiller for new energy testing needs to pay more attention to its maintenance knowledge and carry out a lot of related maintenance work.

Recomendaciones relacionadas

-

¿Cuáles son los componentes del sistema de varios dispositivos de destilación?

8131. A complete set of short-path distillation equipment: including short-path evaporator, heating system, feeding system, cooling system, vacuum system, material collection unit, etc.; 2. A complete set of thin film distillation equipment: includin...

Ver detalles -

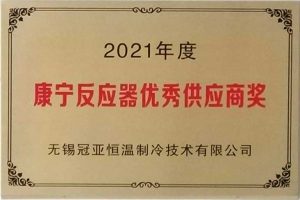

Ganador del premio "Proveedor excelente de equipos de control de temperatura de reactores en 2021"

3032LNEYA fue galardonada con el premio "2021 Proveedor Excelente de Tecnología de Reactores" por Corning, una empresa de la lista Fortune 500 de Estados Unidos. Desde 2015, LNEYA ha ganado este premio durante 7 años consecutivos. Por lo tanto, en la industria de fabricación de reactores, hemos...

Ver detalles -

Importance of refrigerants in new energy vehicle battery test systems

1245If the flow rate of the refrigerant in the new energy vehicle battery test system is extremely small, the refrigerant will start to expand from the first expandable space at the rear end of the throttle valve. Most of the see-up of the rear end of...

Ver detalles -

Brief introduction of explosion-proof curve heating and cooling thermostat

971The explosion-proof curve heating and cooling thermostat SUNDI series adopts compressor refrigeration and linkage heating technology, an integrated piping system, and a plate heat exchanger. It is suitable for equipment connecting reactors for ref...

Ver detalles

LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor