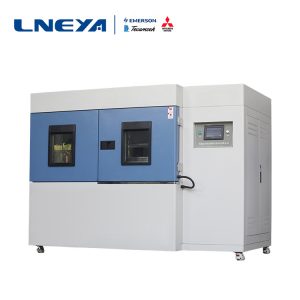

Refrigeration effect of water-cooled chiller at -15℃

The main configurations of water-cooled

chillers are: compressors, electrical components, water pumps, evaporators,

condensers, high/low pressure controllers, high/low pressure gauges, LCD

thermostats, expansion valves, antifreeze switches, hand valves , Fan. Screw

chillers and high-precision constant temperature circulating chillers are

trusted by well-known international and domestic vacuum instruments, analytical

instruments, and other manufacturers.

Water circulation system of water-cooled

chiller:

First inject a certain amount of water into

the water tank of the chiller, cool the water through the chiller refrigeration

system, and then send the low-temperature cooling water to the equipment that

needs to be cooled by the water pump. The chilled water will take away the heat

and increase the temperature before returning to The water tank achieves the

cooling effect. The cooling water temperature can be automatically adjusted

according to requirements, and long-term use can save water. Therefore, the chiller

is a standard environmentally friendly and energy-saving equipment.

Refrigerant circulation system of

water-cooled chiller:

The liquid refrigerant in the evaporator

absorbs the heat in the water and starts to evaporate. Eventually, a certain

temperature difference is formed between the refrigerant and the water. The

liquid refrigerant is also completely evaporated and becomes a gaseous state,

which is sucked by the compressor and compressed (pressure and temperature

increase) , The gaseous refrigerant absorbs heat through the condenser

(air-cooled/water-cooled), condenses into a liquid, and is throttled by a

thermal expansion valve (or capillary tube) to become a low-temperature and

low-pressure refrigerant to enter the evaporator, completing the refrigerant

cycle process.

Features of water-cooled chillers

1. Fully enclosed refrigeration system,

stable work and reliable performance;

2. Digital display and control, high

temperature control accuracy and uniform temperature;

3. Using ultra-quiet circulating water

pump, the whole machine works quietly and has low noise;

4. High-performance refrigeration system

and pump circulation system, suitable for long-term continuous work;

5. Closed water tank and pipeline structure

to avoid coolant pollution and oxidation;

6. Standard stainless steel water inlet and

outlet ports, can be equipped with a variety of joints or hoses, external

closed loop;

7. Real-time display of working status and

alarm status;

8. Microcomputer temperature controller,

temperature digital display, adjustment unit 0.1 degrees Celsius, temperature

range 5~50 adjustable

9. The role of the mechanical industrial

equipment of the chiller: control the pressure oil temperature of the oil

pressure system, stabilize the oil temperature and oil pressure, extend the oil

quality use time, improve the efficiency of mechanical lubrication, and reduce

wear.

Multiple protections for water-cooled

chillers: 1. Over-temperature protection; 2. Current protection; 3.

Self-diagnosis; 4. Intelligent antifreeze; 5. Water flow alarm; 6. Water level

alarm; 7. Pressure alarm; 8. Time switch machine

LNEYA’s water-cooled chillers,

refrigeration circulators and other equipment can be customized in terms of

power, size and temperature range. For details, please contact sales@lneya.com

Recomendaciones relacionadas

-

¿Cómo sustituir la válvula de cuatro vías de un equipo de refrigeración industrial?

882La válvula de cuatro vías del equipo de refrigeración industrial necesita ser reemplazada a tiempo después de un largo período de uso, así que ¿cómo reemplazarla? Para sustituir el equipo de refrigeración industrial, primero debe retirar el tubo de conexión ...

Ver detalles -

Treatment of insufficient exhaust gas in high and low temperature impact test chamber compressor

1183The efficiency of the high and low temperature impact test chamber during use is very important. If there is a shortage of high compressor exhaust, we need our LNEYA technicians to solve it in time. So, how to solve it better? The high and low tem...

Ver detalles -

Closed circulation cooling system debugging attention note

1078Closed circulation cooling system needs to pay attention to some common problems during commissioning. Do a good job in debugging work. LNEYA manufacturers remind users that only when they are ready to work can they be better debugged. The prepara...

Ver detalles -

Why do chemical raw materials require low-temperature chillers?

868The main reasons for using low-temperature chillers in the production process of chemical raw materials are as follows: Temperature control: Many chemical reactions are temperature sensitive and require precise temperature control to...

Ver detalles

LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor