What should do if the equipment of the thermal shock test chamber does not reach the set temperature

The choice of the manufacturer of the thermal shock test chamber is related to the quality of the thermal shock test chamber. Once the quality is set, the temperature setting of the equipment will not be closed. What should I do if I encounter the temperature setting problem?

The temperature set by the thermal shock test chamber is not up to the possibility that the heat exchange humidification tube is broken. You can either repair the factory or replace the new thermal shock test chamber directly. In the high temperature test, if the temperature does not change. When testing the temperature value, the electrical system can be inspected to eliminate the fault one by one, or the temperature probe may be broken, causing the device to not work when the water temperature is lower than the set standard temperature or 37 degrees.

The temperature and temperature of the thermal shock test chamber is too long or the heating tube is aging and damaged. When the actual water temperature is far below 37 degrees, the equipment has not worked, or the work is not working. If the temperature rises directly to cause over-temperature protection, the controller fails and the control instrument must be replaced. If the temperature is too high, you need to set the PID setting parameters first.

If the temperature rises very slowly, it is necessary to check the air circulation system to see if the regulating baffle of the air circulation is normally turned on. If the temperature of the thermal shock test box rises very quickly, check whether the motor of the air circulation is running normally. Because there is a time limit for use, so the running time is too long, it is inevitable that there will be some kinds of various faults, usually pay attention to regular maintenance and maintenance, generally can be largely avoided. If you encounter a large technical problem, you should seek solutions in time with the manufacturer.

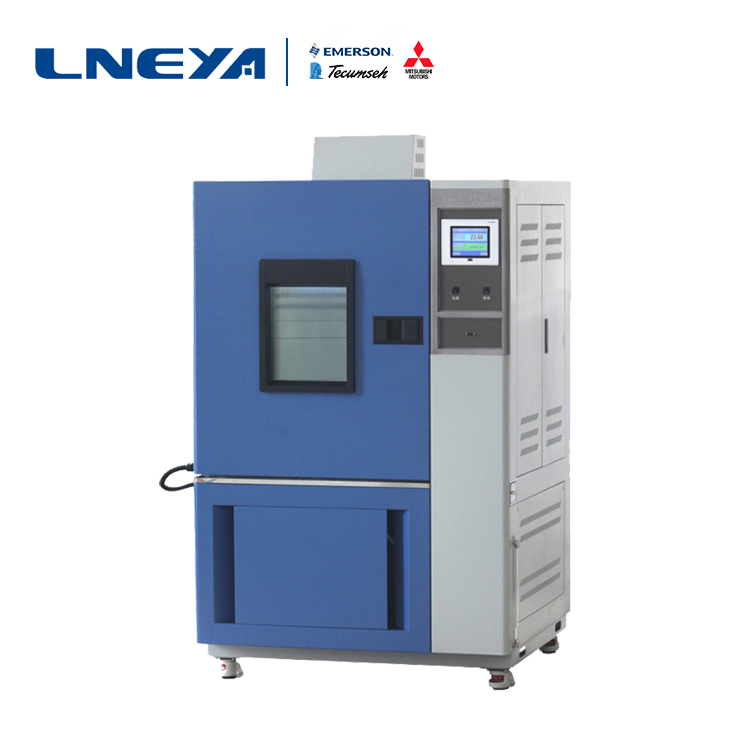

LNEYA thermal shock test box manufacturer is a professional hot and cold impact test box manufacturer integrating R&D, production and sales. It has more than ten years of experience in refrigeration and heating equipment production, and has reached cooperation with many domestic enterprises.

Recomendaciones relacionadas

-

What are the common connection methods for industrial chillers?

1050There are several connection methods for industrial chillers, which are suitable for pipe connection under different conditions. First, welding connectionWelding is the most important and widely used connection method in pipeline engineering. Weld...

Ver detalles -

How to clean the battery cooling system of new energy vehicles?

870The battery cooling system of the new energy model first unscrews the three screws on the upper part of the wet curtain, holds the louvers on the upper part of the wet curtain, gently pulls the wet curtain outward and then lifts it up slightly to ...

Ver detalles -

¿Dónde se utilizará el reactor? ¿Y el sistema de control de la temperatura del reactor?

858Generalmente, los no profesionales deben confundirse sobre el reactor. El reactor está compuesto por el cuerpo del reactor, la cubierta del reactor, la camisa, el agitador, el dispositivo de transmisión, el dispositivo de sellado del eje, el soporte, etc. Generalmente se entiende como un contenedor con fisi...

Ver detalles -

LNEYA jet cooling heating temperature control device application note

936The jet cooling heating temperature control device is applied to components to provide accurate and rapid ambient temperature for chips, modules, integrated circuit boards, electronic components, etc., and is indispensable for product electrical p...

Ver detalles

LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor