Product features of explosion-proof high and low temperature machine

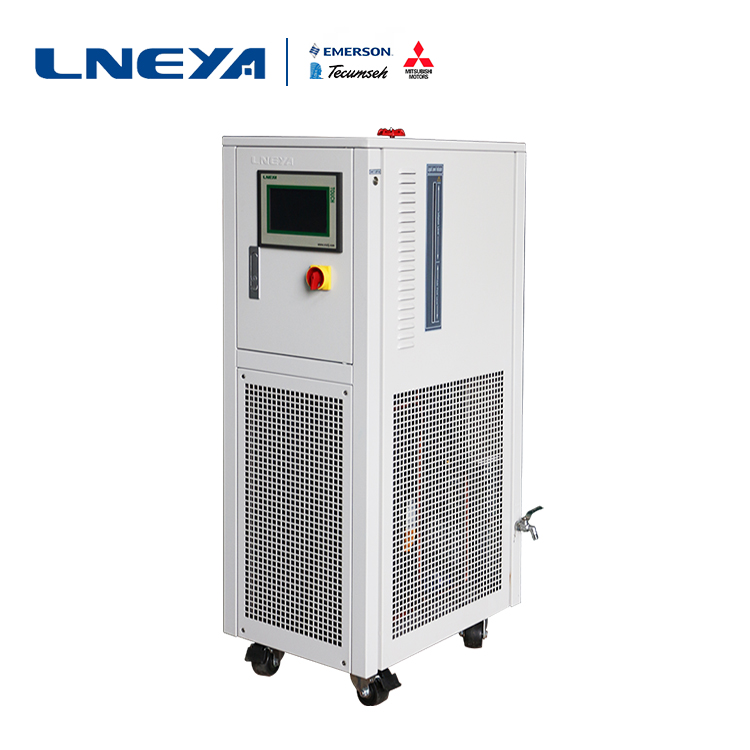

LNEYA explosion-proof high and low temperature machine is a relatively temperature control equipment that can be used in the current heating and cooling system. It can be used for simultaneous cooling and heating. It can be combined with various reactors for stable performance and reliable quality.

Explosion-proof high and low temperature integrated machine special relays, protectors, capacitors, refrigeration components, for the brand original high-quality devices, digital display temperature display, microcomputer temperature control, simple operation, eye-catching. The circulatory system is made of anti-corrosion material and has the functions of anti-rust, anti-corrosion and anti-cold liquid pollution. Explosion-proof high and low temperature integrated machine has energy saving. It can prevent circulating water scaling and anti-pollution when it is lack of water source, water quality and water pressure. It can effectively protect the normal operation of equipment under the bad working environment conditions in high temperature areas.

The explosion-proof high and low temperature integrated machine can meet the dynamic constant temperature control of the cold heat source of the high pressure reactor, the dynamic constant temperature control of the cold and hot source of the double glass reactor, the dynamic constant temperature control of the cold heat source of the double reactor, and the constant temperature control of the cold and heat source of the microchannel reactor. Small thermostat control system, temperature control of steaming system, low temperature and high temperature aging test of materials, combined chemical source cold source heat source constant temperature control, semiconductor equipment cooling and heating, vacuum chamber refrigeration heating constant temperature control and other temperature control needs. The equipment is especially suitable for the chemical, biological, physical laboratory, chemical industry metallurgical industry, colleges and universities, scientific research, genetic engineering, polymer engineering and other laboratories that need to maintain low temperature and work under normal temperature conditions.

No heat transfer medium evaporates at high temperature, and can achieve -80~190 degrees, -70~220 degrees, -88~170 degrees, -55~250 degrees, -30~300 degrees continuous control without pressure temperature. Ultra-high temperature cooling technology can directly cool down from 300 degrees high temperature. This principle and function have many advantages for the user: because only the heat transfer medium in the expansion chamber is in contact with the oxygen in the air (and the temperature of the expansion tank) At room temperature to 60 degrees, the risk of the heat transfer medium being oxidized and absorbing moisture in the air can be reduced.

LNEYA’s temperature control equipment adopts a fully enclosed pipeline design and uses a high-efficiency plate heat exchanger to reduce the demand for thermal fluid while improving the heat utilization rate of the system and achieving rapid rise and fall temperatures.

Recomendaciones relacionadas

-

Descripción de la temperatura de evaporación

1235In the current new energy vehicle battery test equipment, the use of more batteries to test the chiller evaporation temperature has a certain impact on the equipment, then what is the specific impact? When the battery test chiller heat load increa...

Ver detalles -

The Main Application Areas of Air Cooled Chillers

917In the domestic and international industrial water chiller market, our most common industrial water chiller equipment can be roughly divided into two different types, one type is industrial air cooled chiller, the other type is industrial water co...

Ver detalles -

Microscopio electrónico de barrido Sistema de circulación de agua de refrigeración

1055El microscopio electrónico de barrido (SEM) es un microscopio de alta resolución muy utilizado en la ciencia de materiales, la biología, la nanotecnología y otros campos. El SEM genera una cierta cantidad de calor durante su funcionamiento. Para garantizar un funcionamiento estable y...

Ver detalles -

Working Principle and Process of Chiller Temperature Control and Pressure Controller

1563Air cooled chiller temperature controller is a two - position regulator, also known as chiller temperature control relay.According to the change of adjusted temperature,the chiller temperature control makes the contact on or off, thus controlling ...

Ver detalles

LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor