Advantages of bearing cryogenic treatment equipment

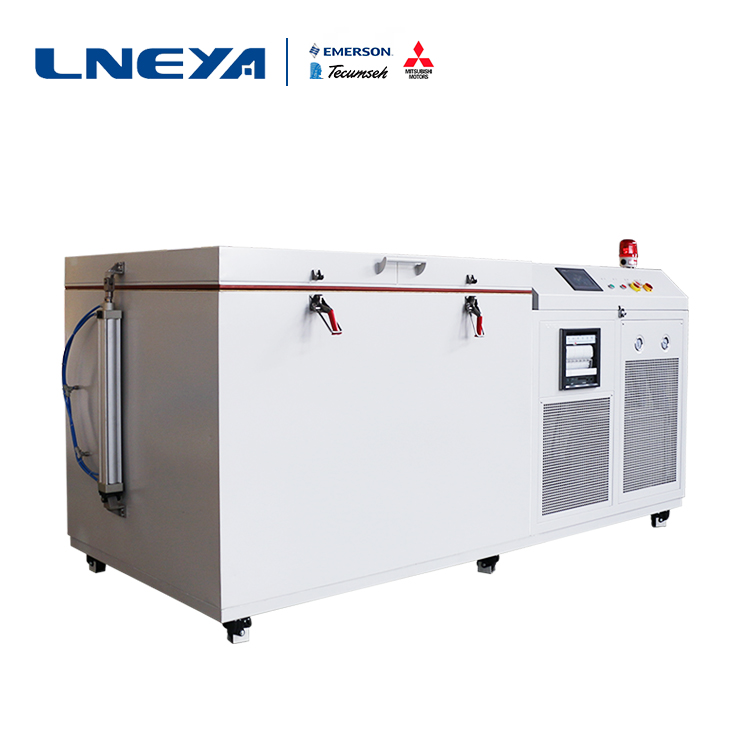

One of the names of the ultra-low temperature freezer is the bearing cryogenic treatment equipment. Wuxi Guanya LNEYA’s ultra-low temperature freezer is designed for large volume ratio; large capacity bearing capacity design; can set the temperature difference between turning on the compressor and turning off the compressor;

A variety of fault alarms (over temperature alarm, sensor alarm, high pressure alarm, compressor overheat alarm).

Cryogenic treatment is a continuation of the workpiece cooling process after quenching. The application in the mold industry is mainly reflected in the application of cryogenic technology in cold work die steel and high speed steel, bearing steel, cold work die and mold parts.

The advantages of cryogenic treatment are as follows:

1. Improve the hardness and strength of the workpiece

2. Guarantee the dimensional accuracy of the workpiece

3. Improve the wear resistance of the workpiece

4. Improve the impact toughness of the workpiece

5. Improve the stress distribution inside the workpiece and improve the fatigue strength

6. Improve the corrosion resistance of the workpiece.

Bearing cryogenic treatment equipment product structure:

The bearing cryogenic treatment equipment adopts 7-inch color touch screen (display set temperature, measurement temperature), temperature curve record, U disk data export, format is excel table, fault record, real-time monitoring temperature change inside the box, with manual and automatic double operation function . The equipment uses liquid nitrogen as the cooling medium, and the stainless steel cabinet is beautiful and durable, and is insulated by high-quality high-density polyurethane foam insulation layer. The system structure is reasonable, the manufacturing process is standardized, the components are arranged compactly, the operation is simple and powerful, and the humanized communication interface; the low temperature can reach -150 ° C, and the cooling speed is fast. The ultra-low temperature cryogenic test chamber adopts (developed by itself) Guanya company mixed refrigerant, which makes the process of constant temperature and temperature drop of the product even and stable.

Application range:

It is mainly used in industrial cold treatment to precipitate uniform, fine and dispersed carbides generated on the metal structure matrix. The appearance of such a carbide will bring about a significant increase in the wear resistance and friction properties of the metal, and the hardness will also increase, and will directly increase the life of the wear member. The ideal product to replace liquid nitrogen.

It is used for shrinkage of copper sleeves, bearings, etc., and is widely used in precision mechanical assembly. It is used in ultra-low temperature testing of large equipment (automobiles, large construction machinery, aircraft components, aerospace equipment components, military equipment components).

Recomendaciones relacionadas

-

Working Principle and Process of Chiller Temperature Control and Pressure Controller

1557Air cooled chiller temperature controller is a two - position regulator, also known as chiller temperature control relay.According to the change of adjusted temperature,the chiller temperature control makes the contact on or off, thus controlling ...

Ver detalles -

Small hot and cold shock test box use note

1046Small thermal shock test chamber is non-explosion-proof product (explosion-proof needs to be customized), please do not use it in the environment with flammable or explosive gas. In order to avoid small thermal shock, the test box is faulty, pleas...

Ver detalles -

Varios aspectos de atención del ultracongelador

1224El rendimiento del congelador de ultra baja temperatura se reducirá naturalmente debido a la aplicación de largo período en todos los campos. Por lo tanto, Guanya Refrigeration Technology Co., Ltd, líder en fabricantes de congeladores de temperatura ultra baja tiene que recordar a todos los usuarios...

Ver detalles -

LNEYA es una empresa de élite que produce sistemas profesionales de detección de motores de vehículos de nueva energía.

1563In the development of modern automobiles, new energy vehicles have become the mainstream era of contemporary automobile development. Among them, the drive motor system is one of the main components of new energy vehicles, and its performance is ...

Ver detalles

LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor