KRYO 0℃~160℃

Oil Cooling Chiller- Precisión de la temperatura±0.3℃

- Flow Accuracy±0.2L/min

- Capacidad de refrigeración12kW~38kW

- Heating Capacity15kW~38kW

- Salida de caudal1~40 L/min

- RefrigeranteAceite

Cooling and heating temperature and flow control

The object under test is connected to a test platform adapter

The component is cooled and heated by ethylene glycol water solution

-40’C~100°C (expandable to 150°C)

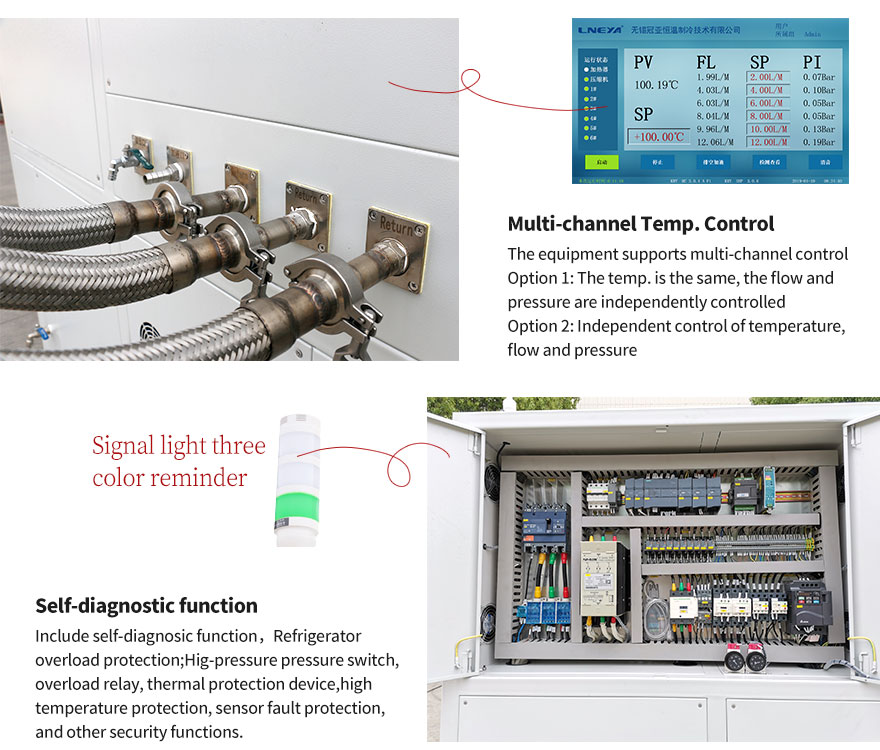

- Pantalla táctil a color

- Equipment power switch

- Liquid level light

- High and low pressure gauges

- Communication interface

- Four-way casters

- Circulation pipeline

- Electrical cabinet

- Compressor circulation pump

| KRYO SERIES | A15W | A25W | A38W | A15W2S | A25W2S | A38W2S | |

| Rango de temperatura | 0℃ ~ +160℃ Different viscosity oils have different temperature ranges | ||||||

| Control de la temperatura precisión | ±0.3℃ | ||||||

| Retroalimentación de temperatura | PT100 | ||||||

| Control del caudal | 2L/min~20L/min, one in and one out, in and out control linkage | 2L/min~15L/min Two outputs, one input Flow control linkage | |||||

| Flow accuracy | ±0.2L/min | ||||||

| Control de la presión | 0.2bar~2.5bar | ||||||

| Potencia de calefacción kW | 15 | 25 | 38 | 15 | 25 | 38 | |

| Potencia frigorífica kW | 125℃ | 15 | 25 | 38 | 15 | 25 | 38 |

| 20℃ | 12 | 20 | 30 | 12 | 20 | 30 | |

| Compresor | Emerson Copeland Scroll Flexible Compressor/Japanese Scroll Flexible Compressor | ||||||

| Método de estrangulamiento | Válvula de expansión electrónica | ||||||

| Evaporador | Intercambiador de calor de placas | ||||||

| Bomba de circulación | Gear Pumps | ||||||

| Flow regulation | Inverter vector control | ||||||

| Entrada, Pantalla | 7-inch color touch screen/PLC controller | ||||||

| Comunicaciones | CAN communication | ||||||

| Refrigerante | R410A | ||||||

| Refrigerante | Aceite | ||||||

| Liquid inlet and outlet | G3/4 | ||||||

| Cooling water @20℃ | 3000L/H | 4200L/H | 6200L/H | 3000L/H | 4200L/H | 6200L/H | |

| Conexión de agua de refrigeración | G3/4 | G3/4 | G1 | G3/4 | G3/4 | G1 | |

| power supply | 380V 50HZ three-phase five-wire | ||||||

| Interruptor | 50A | 80A | 125A | 50A | 80A | 125A | |

| External tooling | External oil return tooling size 600×850×600 | ||||||

| If the external oil return fixture is selected, the fixture needs to be installed under the test motor. | |||||||

Descriptions

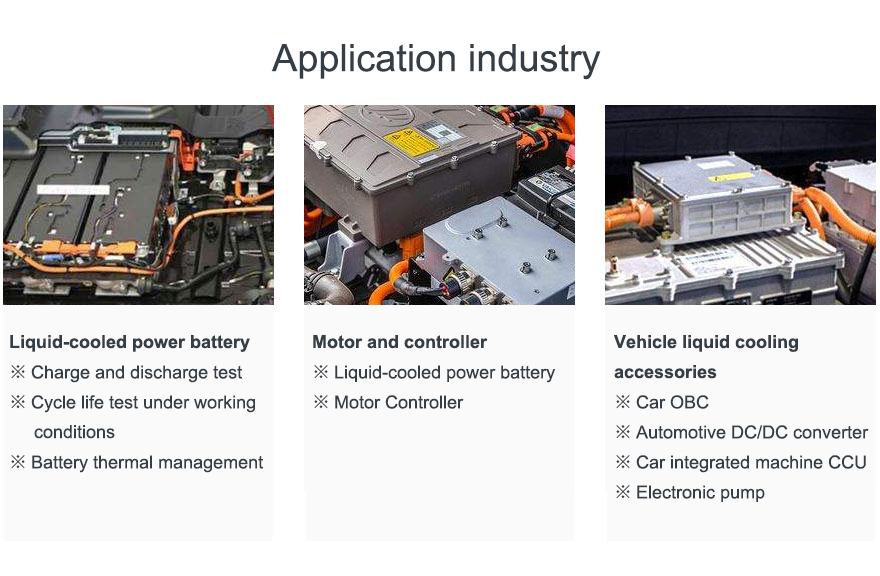

Para la gestión de carga de la batería de potencia, el dispositivo de control de temperatura de precisión para probar el motor síncrono de imanes permanentes, el motor de reluctancia conmutada, el motor asíncrono y su controlador pueden realizar el modo de control local + remoto a través del panel controlador de cristal líquido;

Con función de protección automática contra fallos, puede emitir las señales correspondientes para garantizar la seguridad del equipo. Las piezas principales son todas las marcas internacionales, garantía de calidad, tratamiento de pulverización electrostática de alta presión en la superficie, y el equipo auxiliar se puede añadir de acuerdo a las necesidades específicas.

recomendar productos

KRY -40℃~+100℃ (1to6)

KRY -40℃~+100℃ (1to6)

The components are cooled and heated internally through ethylene glycol aqueous solution for testing -40 ° C~100 ° C (expandable to 150 ° C) For the power battery charging management, the precision …

KRY -40℃~+100℃ (1to1)

KRY -40℃~+100℃ (1to1)

Refrigeration, heating, temperature control, flow control Connect the tested object to a testing platform adapterThe components are cooled and heated internally through ethylene glycol aqueous solution for testing. …

KRY -40℃~+100℃ (1to2)

KRY -40℃~+100℃ (1to2)

Temperature range is -40℃~+100℃, which can be extended to +135℃ according to the actual situation, and the temperature control accuracy is plus or minus 0.5℃. Theequipment can control the flow and pressure independently while c…

KRY -40℃~+100℃ (1to3)

KRY -40℃~+100℃ (1to3)

Dimension(A) cm Temperature range is -40℃~+100℃, which can be extended to +135℃ according to the actual situation, and the temperature control accuracy is plus or minus 0.5℃. Theequipment can control the flow and…

loading…

已经是到最后一篇内容了!

LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor