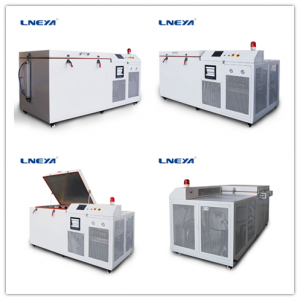

Maintenance and maintenance of battery pack test temperature simulation chiller

The battery pack test temperature simulation chiller is more and more widely used in enterprises, but the subsequent maintenance and maintenance are also more important. Here is a brief introduction to some maintenance and maintenance methods.

1. The temperature of the battery pack that does not need to be opened is not closed before the start-up to simulate the water inlet valve of the condenser on the chiller, resulting in water leakage. Part of the cooling return water flows away from the condenser of the non-starting unit, reducing the cooling water flow in the condenser of the operating unit, causing the condensation pressure to rise, the operating current of the main engine to increase, and the cooling capacity of the unit to decrease. Stopping the operation not only wastes electricity, but also reduces the cooling effect, and is easy to damage the equipment.

2. Before starting up, close the water inlet valve of the condenser of the unit that does not need to be operated to prevent water leakage. Open the water inlet and outlet valves on the condenser of the unit to be operated (generally the outlet valve is normally open, the water inlet valve is opened and closed according to needs. The condenser and the evaporator are the same) and turn on the corresponding cooling water pump to adjust the water inlet and outlet pressure of the condenser.

3. If the pointer of the pressure gauge of the water inlet and outlet of the condenser swings too much, it means that there is air in the equipment system, and the air needs to be exhausted to continue to the next step after the pressure gauge indicates normal.

4. It adopts an intelligent main control board, and the LED display is stable and durable, with multiple settings and fault display functions; it is equipped with a water outlet pressure gauge, which is convenient for observing pressure and flow.

Recomendaciones relacionadas

-

Precautions for customers installing Lneya’s cryogenic industrial chillers

1824One. When installing low-temperature industrial chillers, you need to pay attention to some installation requirements. 1. The cryogenic industrial chiller should be installed directly in a horizontal position, do not install it upside down or dia...

Ver detalles -

¿Cómo resolver el fenómeno del cilindro de tarjeta de congelación a temperatura ultrabaja?

2210Si el congelador de ultra baja temperatura falla durante el funcionamiento, es necesario resolverlo a tiempo. Si es similar al fenómeno relacionado, puede ser que el aceite congelado no salga, y el operador necesita resolverlo a tiempo. Temperatura ultrabaja...

Ver detalles -

Descripción del método de mantenimiento de la máquina de temperatura de un molde frío y caliente

1858In the process of using the hot and cold integrated mold temperature machine, it is necessary to carry out regular maintenance and repair. Then, LNEYA will share with you the maintenance method of the hot and cold integrated mold temperature machi...

Ver detalles -

Micro-channel reactor thermostatically controlled air-cooled chiller compressor troubleshooting meth

1780The air-cooled chiller is a temperaturecontrol device that is widely used in the microchannel reactor industry. WuxiGuanya LNEYA has produced a cold and heat source thermostatically controlledair-cooled chiller for the microchannel reactor indu...

Ver detalles

LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor