Conocimientos sobre seguridad del sistema de circulación secundaria de aceite térmico

The thermal oil secondary circulation system is equipped with various instruments and equipment for temperature control. After market research, carefully research and production of temperature-controlled products, when using, you need to pay attention to its safety knowledge, safer use of thermal oil secondary circulation system.

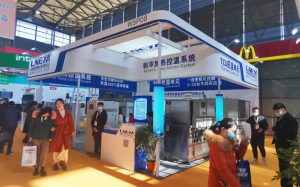

LNEYA heat transfer oil secondary circulation system uses branded fully enclosed compressors with advanced performance and reliable quality. The relay, protector and capacitor used in the refrigeration unit of the heat transfer oil secondary circulation system are all original high-quality equipment, ensuring reliable performance and long service life. It integrates cooling, heating and circulation, and the power is reasonable and saves space.

Liquid medium should be added in the tank before use. Generally, the liquid level is 30mm-50mm below the working surface to prevent the heater from being burnt. The power supply is 220VAC/50Hz, and the equipment must have good grounding. The circulating pump of the heat transfer oil secondary circulation system is automatically opened when the equipment starts to operate, and the refrigeration compressor will make corresponding start or stop command operation according to the temperature of the equipment unless there is a special need.

LNEYA heat transfer oil secondary circulation system adopts the automatic control function of circulating pump, that is, when the equipment is running, the circulation pump runs automatically. When the equipment is running, because of the function of the self-contained circulation pump, the liquid surface will show a flowing pattern if running. When there is no obvious flow state at the liquid tank interface, it means that there may be a helium state, and it should be exhausted in time. With its own cooling function, the cooling function can automatically issue a running or stop command according to the temperature of the device, or it can artificially prohibit the compressor from running through the system parameters. When the device prohibits the compressor from running, the compressor needs to be set again to restore normal cooling. run.

The secondary circulation system of the heat transfer oil shall be placed in a ventilated and dry place, and the back and sides shall be separated from the obstacle by more than 300 mm. The secondary circulation system of the heat transfer oil is used, the power switch is turned off, and the power plug is unplugged. If it is not used for a long time, the liquid in the tank should be drained and scrubbed clean.

When the heat transfer oil secondary circulation system is used, it is necessary to pay more attention to the above problems in order to achieve more efficient operation efficiency.

Recomendaciones relacionadas

-

Semiconductor refrigeration temperature control system accessories

1758In the evaporator, since the liquid evaporates in the evaporator of the semiconductor refrigeration temperature control system, the process from liquid to gas, due to the change of the load, some of the refrigerant may not be completely evaporated...

Ver detalles -

-

-

Precautions for installing reactor refrigeration and heating cycle equipment

2248reactor temperature control unit installing

Ver detalles

LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor