Description of the action of the filter in the ultra-low temperature compressor unit

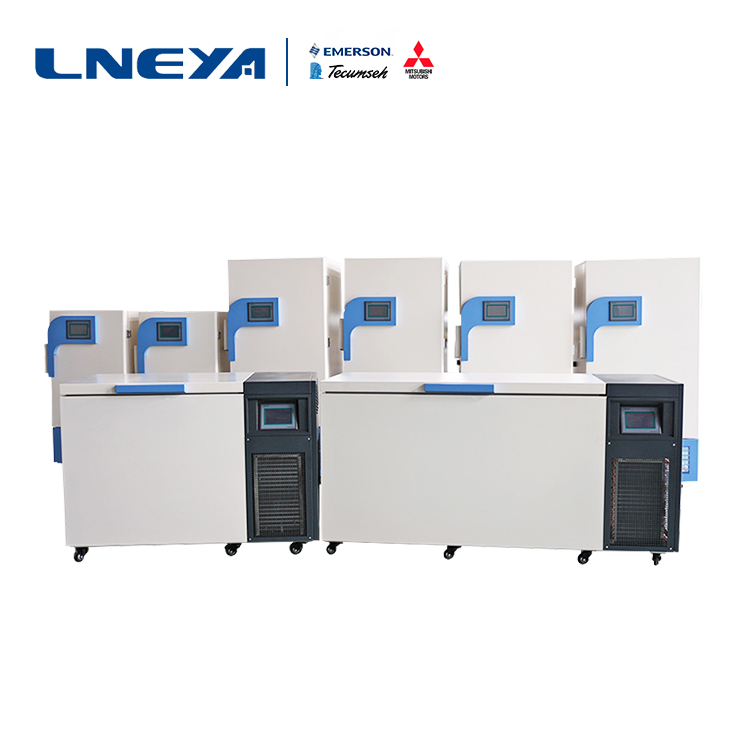

In order to stabilize the operation of the ultra-low temperature compressor unit, the performance of the compressor is very important, and in addition to the compressor, the filter is also important.

In order to maintain normal operation, it is necessary to ensure the normal use of the refrigerant. In the entire ultra-low temperature compressor cycle system, the refrigerant cannot be completely unaffected. During the normal cycle operation, the refrigerant will contain more and more. Metal scraps, as well as other magazines, are inevitable in normal operation.

However, if the refrigerant contains these impurities, it will definitely affect its normal operation, which will seriously affect the overall refrigeration quality of the ultra-low temperature compressor unit. At the same time, it will cause damage to the compressor and other components. Therefore, the refrigerant needs to be filtered. This is the filter. Play a role.

Ultra-low temperature compressor set filter refers to the device that provides filtration service for the refrigerant. Usually it is put together with the dryer. It is two-in-one, but the filter itself can be cleaned, cleaned and replaced separately. In general, in industrial ultra-low temperature compressor units, there must be a filter device. The filter does not have any deep design, that is, through the extremely dense mesh device, the metal debris and other materials in the refrigerant. Impurities are filtered.

The function of the filter is simply to clean the refrigerant and allow the refrigerant to be recycled many times. If there is no filter, the refrigerant can not be recycled normally. It may be a few days later. The maintenance of the filter also requires a snack. The frequency and various aspects of the filter in the ultra-low temperature compressor group under different environments and different operating intensities are also different. Secondly, if conditions permit, it is recommended to replace the filter once a month, or three months later, otherwise it will affect the use of the filter.

Of course, the different types of filter models of the ultra-low temperature compressor group are also different, and the user can select the corresponding condenser according to the specific working conditions.

Recomendaciones relacionadas

-

The Refrigeration System of a Cryogenic Chiller

1630In recent years, cryogenic chiller products are more and more common in the domestic industrial market. Many industrial productions need more help from cryogenic chiller products to achieve the ideal low-temperature environment. Therefore, cryogen...

Ver detalles -

Lneya Semiconductor High Precision Temperature Control System Description

2105Semiconductor high-precision temperature control systems are currently produced in the semiconductor industry with highly complex performance. Here is a description of the semiconductor high-precision temperature control system. Along with large-s...

Ver detalles -

Storage tank cooling refrigeration chiller

1408Tank cooling chiller is a device specifically used to cool materials in a tank to ensure that the materials in the tank are stored within a suitable temperature range to maintain the quality and performance of the materials. This type of c...

Ver detalles -

Cooling and heating of the reactor and the principle of use

1918Cooling and heating circulator thermostats are commonly used with glass reactors for biochemical instruments. They are widely used in modern fine chemicals, biopharmaceuticals, scientific research and experiment industries. They can be concentrate...

Ver detalles

LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor