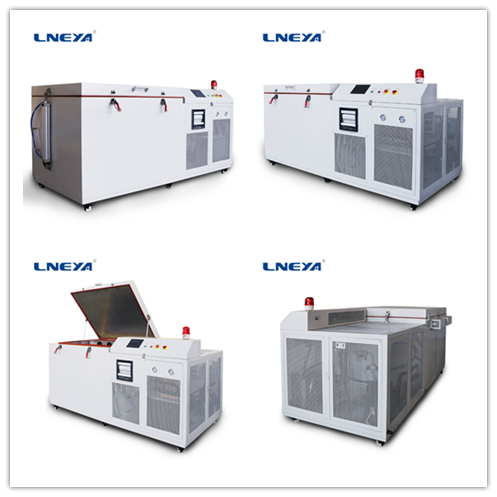

Instructions to Use Industrial Cryogenic Refrigerator

Industrial refrigerators are one of the cold water machines. It is classified according to the cooling mode of the cold water machine itself. It is divided into air cooling type refrigerators and water cooled refrigerators.

Structural features: a standard refrigerator freezer is composed of a compressor, condenser, evaporator, filter drier, expansion throttling valve of the five most series, note the amount of refrigerant inside (refrigerant), the electrical appliances (including controller) according to the requirement of the environment and control the operation of the compressor to achieve the purpose of heat transfer and refrigeration.

With the progress of the society, the industry has also been developed rapidly. Today, we will discuss the use of the laboratory refrigerator (industrial refrigerator).

1. Always check the sealing strip of the outer door.

2. Place it firmly and horizontally on the ground when carrying.

3. Clean the filter once a month (use a vacuum cleaner to suck, rinse it with water, finally dry and reset the filter), and suck the dust on the internal condenser with a vacuum cleaner in every two months.

4. When defrosting, you should cut off the power and open the door. When the ice and cream begin to melt, put in each layer of the refrigerator clean and bibulous cloth.

5. Clean it every month to make sure it is clean.

6. Remove the small amount of the dustin the fridge on the internal and external and accessories with dry cloth. If the fridge is too dirty, use neutral detergent and wash thoroughly with clean water after washing. Do not rinse the inside and upside of the refrigerator with water, otherwise, it will damage the insulation and cause failure.

7. Don’t put the lubricating oil to the compressor and other mechanical parts.

8. Take care when cleaning the fans in the back of the compressor.

9. The maintenance and maintenance of cryogenic refrigerator is particularly important to extend the life and the normal use. If the temperature control is not accurate, it often leads to damage the saved objects which will cause great influence to the experimental results, thus affecting the normal work.

Recomendaciones relacionadas

-

¿Qué es la falta de aceite en el frigorífico de temperatura ultrabaja de 120 grados?

1845The compressor of the -120 degree ultra-low temperature refrigerator is a complex component that runs at high speed. In order to ensure sufficient lubrication of the moving parts of the compressor crankshaft, bearings, connecting rods, pistons, et...

Ver detalles -

The reason for the high pressure alarm of the TCU integrated temperature control unit

1583When the TCU integrated temperature control unit is used, it needs to be used according to the instructions in detail. Once problems are encountered, they need to be dealt with in time. Generally speaking, if we encounter a high pressure alarm fro...

Ver detalles -

Características del refrigerador industrial de recirculación a temperatura constante

2224Puntos de atención en el uso del enfriador industrial de recirculación a temperatura constanteLos enfriadores industriales de recirculación a temperatura constante se utilizan ampliamente en los sectores farmacéutico, químico y de laboratorio. A continuación, vamos a introducir las características...

Ver detalles -

LNEYA se puso a la cabeza de las auditorías en línea en directo

2203Good products come from a strict manufacturing process. In March 2020, LNEYA took the lead in adopting the methods of cloud supervision and factory inspection, focusing on the display of LNEYA refrigeration heating temperature control device, TCU ...

Ver detalles

LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor