¿Por qué los gases especiales utilizados en los procesos de fabricación de semiconductores requieren refrigeradores?

If you have any questions, please contact us

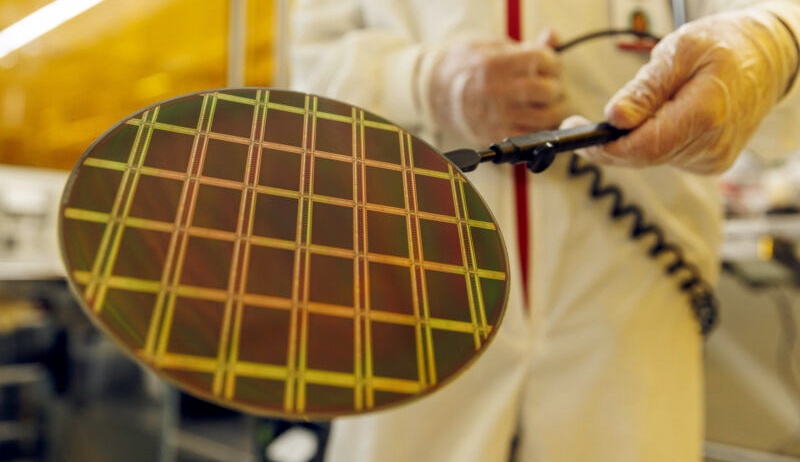

When using special gases in semiconductor manufacturing processes, a chiller is required, mainly due to the following reasons:

- Gas purity control: Special gases are used as raw materials in semiconductor manufacturing, and their purity is crucial to the performance of the final semiconductor device. Some special gases are prone to decomposition or react with impurities such as oxygen and water vapor at high temperatures, reducing their purity. The low-temperature environment provided by the chiller helps maintain the purity of gas during storage and transportation.

- Gas transportation and storage: Some special gases are easy to store in a liquefied state

Transportation, chillers can be used to cool gases to low temperatures, liquefy them, and facilitate storage and metering. Meanwhile, a low-temperature environment is beneficial for slowing down the natural evaporation rate of gases and reducing losses.

3. Process requirements: In semiconductor manufacturing processes such as chemical vapor deposition (CVD), physical vapor deposition (PVD), atomic layer deposition (ALD), etc., gas needs to go through a pre-treatment system, including a cooling system, before entering the reaction chamber to maintain gas transport at a specific temperature and prevent gas preheating or premature reaction in the pipeline.

4. Equipment cooling: Semiconductor production equipment generates a large amount of heat during operation, and requires a chiller to provide cooling for its internal gas delivery pipelines, reaction chambers, and other components to ensure that the gas maintains a stable temperature when entering and leaving the chamber. This is crucial for precise process control and product quality.

5. Safety considerations: Some special gases may become unstable or flammable and explosive at high temperatures. Using a chiller can reduce the risk of gas leakage accidents and ensure the safety of the entire process.

Therefore, the chiller is crucial for the storage, treatment, and use of special gases in the semiconductor manufacturing process, and is one of the key equipment to ensure the smooth progress of the semiconductor manufacturing process.

Solicitar un presupuesto

Proporcionar 7 * 24 consulta gratuita y soluciones integrales

Recomendaciones relacionadas

-

Cómo resolver el problema de la insuficiente capacidad de refrigeración del sistema de ciclo de refrigeración de semiconductores?

2002The semiconductor cooling cycle system is a device for cooling the semiconductor heating part. LushiA reminds that if the cooling capacity is insufficient during the operation, it is necessary to check in time to see if something has gone wrong. W...

Ver detalles -

Simulation control of temperature change in the cooling and heating temperature control system of th

1353Industrial cooling and heating temperature control system is a temperature control equipment used in the cooling and heating process of reaction kettle in the pharmaceutical and chemical industry. What are the characteristics of lneya's equipment?...

Ver detalles -

Principio del sistema de control de temperatura TCU

2099Área de uso: puede utilizarse en varias áreas a prueba de explosiones La unidad de control de temperatura (TCU) se utiliza principalmente en la calefacción de reactores, control de temperatura de refrigeración en química fina, química farmacéutica y procesos biofarmacéuticos. Puede realizar aut...

Ver detalles -

Inspección de mantenimiento de la unidad de refrigeración de baja temperatura

1751Low-temperature refrigeration units usually need to do a maintenance. After the maintenance is done, it is not easy to fail, and there will be more markets. If it is not easy to fail, it will not stop working, which is equivalent to saving the com...

Ver detalles

LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor

Someter a consulta

Le responderemos en 24 horas