Pequeño golpe para tratar el bloqueo por hielo de los enfriadores de circulación de líquido de alta y baja temperatura

En el funcionamiento de las enfriadoras por circulación de líquido de alta y baja temperatura, el atasco de hielo es un fallo relativamente común. Basándonos en la experiencia de los fabricantes pertinentes, hemos recopilado especialmente consejos relevantes para solucionar los atascos de hielo. En la tubería...

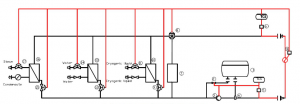

In the pipeline of the high and low temperature liquid circulating chiller, if ice blockage occurs, it is recommended to replace the damaged pipe section and repair the missing spot welding first, and redo and tighten the loose threaded joint. In order to ensure that there is no leakage in the high-pressure test of the high and low temperature liquid circulating water chiller pipeline. The high and low temperature liquid cycle chiller refrigeration cycle system pipeline is divided into high pressure section and low pressure section, flushed with four-recording carbon, and purged with nitrogen to seal for later use.

At the same time, the high and low temperature liquid circulating chiller compressor unit must be strictly processed in accordance with the steps, replacing the new filter of the high and low temperature liquid circulating water chiller, and then blown and sealed for use. The high and low temperature liquid circulating chiller refrigeration cycle system pipeline is unsealed and the compressor unit is quickly assembled After that, perform quantitative charging of the refrigerant, and wait for five minutes (waiting for the static equilibrium of the pressure in the high-pressure zone and low-pressure zone in the refrigeration cycle system pipeline) to power on and test the machine.

When the user usually faces the operation of high and low temperature liquid circulating chillers, they need to pay attention to moisture prevention and seal or seal the parts of the high and low temperature liquid circulating water coolers that are not being repaired. Maintenance is carried out in rainy weather.

However, there is always a case in case. For high and low temperature liquid circulating chillers with slight ice blockage after maintenance, the refrigerant can be recovered, replaced with new filters, or connected in series with a large cubic freezer filter at the high-pressure exhaust end, or even Refill the refrigerant quantitatively.

There are one or two ways to face the phenomenon of ice blockage in high and low temperature liquid circulating chillers. If the user does not know how to solve it, do not solve it blindly by himself. It is recommended to find a professional maintenance person to solve it.

Recomendaciones relacionadas

-

The necessity of temperature heating and cooling cycle in the process of catalytic hydrogenation

1750In recent years, with the rising price of oil, the demand for benzene obtained from coking benzene has increased, coupled with the country's increasing emphasis on environmental protection, the widespread application of coking benzene hydrogenatio...

Ver detalles -

Chemical synthesis process control system temperature control system TCU

1796Today, let's talk about our DCS integrated control system (temperature and other control of synthetic process). Scalability: the system is an open system, which provides standard TCP / P data communication interface protocol, interface software an...

Ver detalles -

Forma de configuración de la unidad de calefacción por circulación para laboratorio

1536El modelo estándar de la unidad de calefacción de circulación para el laboratorio LNEYA es: SUNDI, el rango de temperatura es de temperatura ambiente a menos 120 grados Celsius, y la capacidad se puede dividir en 5L, 10L, 20L, 30L, 40L, 50L, 80L, 100L, mayor cap...

Ver detalles -

Características del sistema de control de temperatura para transferencia de calor de fluidos

1726El sistema de control de temperatura de transferencia de calor de fluidos es el dispositivo de refrigeración y calefacción del reactor de adaptación en la industria química farmacéutica. Por lo tanto, ¿cuáles son las características del sistema de control de temperatura...

Ver detalles

LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor