Mantenimiento del condensador en enfriadoras de baja temperatura

En los últimos años, con la mejora del nivel de producción industrial de China, muchas máquinas y equipos industriales profesionales proporcionan una mayor ayuda para diferentes producciones industriales. Como un equipo de refrigeración industrial muy práctico, Los refrigeradores de baja temperatura pueden proporcionar el mejor entorno de trabajo criogénico para diferentes tipos de producción industrial. Para los refrigeradores de baja temperatura, el condensador es un componente muy importante del equipo. ¿Cómo mantener el condensador en buen estado? baja temperatura refrigeradores?

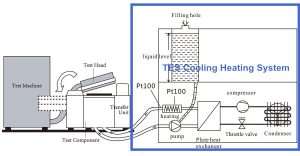

El condensador de los refrigeradores de baja temperatura es un importante componente de refrigeración. Es muy importante mantener el entorno de funcionamiento criogénico de los refrigeradores de baja temperatura. A veces, en el funcionamiento real, si a menudo se produce una sobrecarga de alta presión, limpie el condensador lo antes posible. El refrigerador de baja temperatura es un gas refrigerante que sale del evaporador. Después de la compresión adiabática por el compresor, se convierte en un estado de alta temperatura y presión. Este es el estado inicial de funcionamiento del condensador.

El condensador del refrigerador de baja temperatura normalmente tiene que ser operado y operado completamente para lograr el mejor efecto de refrigeración, asegurando así el mejor ambiente criogénico. En el condensador del refrigerador de baja temperatura, la refrigeración isobárica y la condensación cambian a refrigerante líquido después de la condensación, y luego se expanden a baja presión a través de la válvula de mariposa para convertirse en una mezcla de gas y líquido. El refrigerante líquido a baja temperatura y baja presión absorbe el calor del material refrigerado en el evaporador. Este es todo el proceso del ciclo de refrigeración.

Recomendaciones relacionadas

-

Control de la temperatura durante la prueba de baterías de vehículos de nueva energía

1843With the continuous implementation of energy saving and emission reduction policies, new energy power batteries are also continuously encouraged to develop, and liquid cooling systems have become an inevitable trend for new energy vehicles. The or...

Ver detalles -

How is the electric vehicle battery test driver grounded?

1508If the electric vehicle battery test is not isolated between the AC power source and the drive DC bus (such as a transformer), do not connect the non-isolated port of the DC bus or the ground of the non-isolated signal to the ground, which may res...

Ver detalles -

Chiller for heat deflection temperature instrument

1646Temperature range: The temperature of the cooling water is usually required to be between 6 ℃ and 18 ℃.Temperature difference requirement: The temperature difference of the cooling water should be controlled wit...

Ver detalles -

The significance of temperature in IC testing

2549Every integrated circuit (IC) goes through two type of tests before it can be sold and used to build a product: the first is called a wafer test; the second is called final test. With the improvement of integrated circuit electrical test technolog...

Ver detalles

LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor