The significance of temperature in IC testing

Every integrated circuit (IC) goes through two type of tests before it can be sold and used to build a product: the first is called a wafer test; the second is called final test.

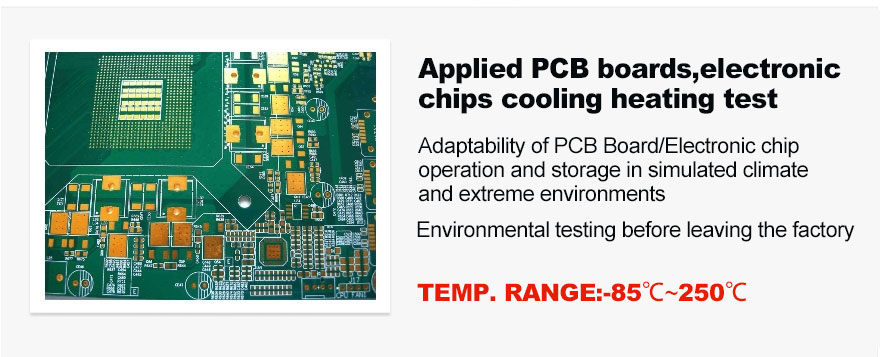

With the improvement of integrated circuit electrical test technology and requirements, some chip products have integrated temperature sensors, or through the voltage changes of some precision diodes linearly related to temperature changes, the current actual chip under test is calculated through a series of formulas temperature.

This means that if the temperature does not meet the standard, it will also be regarded as a defective product, which will also affect the yield of the final test, and due to the inaccuracy of the temperature, it will also cause some electrical test failures. Therefore, the temperature control problem in the final test of the semiconductor is beginning to be taken seriously.

Under normal circumstances, the low temperature test is -40 ℃, the upper and lower limits of the test program temperature test items are controlled at +/- 10 ℃, and more strictly +/- 5 ℃. In the manufacturing of semiconductors electronic components for harsh environments, the IC package assembly and test stages of engineering and production include burn-in, electronic hot and cold testing at temperature, and other environmental test simulations. These semiconductor devices and electronics, once put in real world applications, can get exposed to extreme environmental conditions.

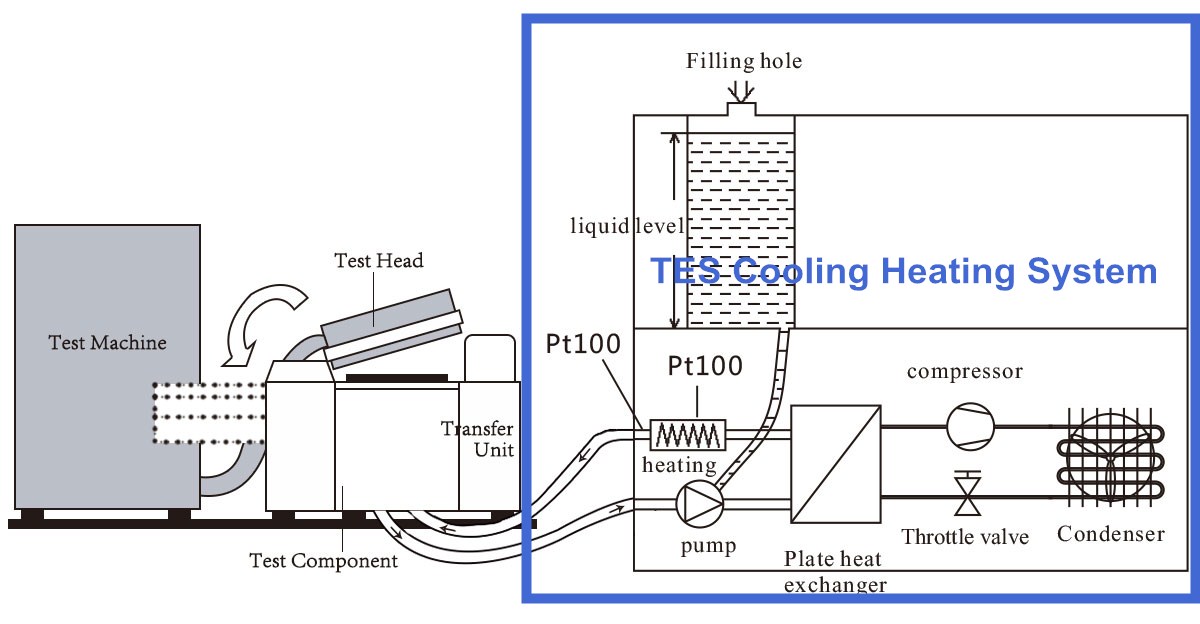

The LNEYA TES-85 has a temperature range from -80 ° C to + 225 ° C without the use of LN2 or CO2. Just connect the pipeline to the test area of the IC and other test benches, This lets you easily temperature test your electronic semiconductor IC devices.

Precision Temperature Forcing Systems use a direct temperature-controlled stream of hot or cold air to provide a precise thermal environment for temperature testing, conditioning and cycling of electronic and non-electronic assemblies and sub-systems. The ThermalAir Temperature System enables the test. This allows you to perform temperature simulation tests in situ, at a specific location, at your tester station, test bench or directly on the unit under test.

Bring temperature to your test for Semiconductor IC devices and other semiconductor packages. LNEYA TES series equipment temperature control range: -85 ° C ~ 200 ° C; power range: 2.5kW ~ 25kW; temperature control accuracy: ± 0.3 ° C. The pressure of the refrigeration system is realized by a pressure gauge (high pressure, low pressure); the pressure of the circulation system is detected by the pressure sensor and displayed on the touch operation screen. Refrigerant uses R404A R23 / R14 mixed refrigerant environmentally friendly refrigerant.

Recomendaciones relacionadas

-

Operation and Maintenance of Small Water Chiller Units

14302. Air-cooled module internal filter, in order to better filter impurities in the water system, the protective plate heat exchanger is generally more than 40 meshes, that is to say, its filter is more dense and finer than other brands. The advanta...

Ver detalles -

¿Cómo elegir un reactor de vidrio? Cómo ajustar el sistema de control de temperatura?

1566Glass kettle reactors are required for many laboratory equipment and are generally used with temperature control systems. In the chemical and pharmaceutical fields, the imported glass reactor is basically a necessity, and the refrigeration heatin...

Ver detalles -

Sistema de calefacción de la torre de destilación

1809Las torres de destilación y los procesos de las torres de destilación requieren, de hecho, enfriadores y sistemas de calefacción para mantener el control de la temperatura durante el proceso, garantizando la eficacia de las operaciones de separación y purificación. La temperatura superior de la ...

Ver detalles -

How to deal with the equipment failure alarm of the recirculation chiller

1503What to do if there is a failure and alarmduring the use of the recirculating chiller equipment? In order to ensureproduction, such problems need to be resolved quickly. We must first understand the causes offailures and alarms, and adopt dif...

Ver detalles

LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor