How to solve the fault of the ultra-low temperature refrigerator pressure controller?

If the industrial ultra-low temperature refrigerator encounters a controller-related failure during operation, if it is not resolved in time, the pressure controller may be unavailable.

The pressure controller plays a very important role in the ultra-low temperature refrigerator group. Because of the pressure exerted between each accessory under the high-efficiency working state, the range is different.

In order to reduce the impact of pressure on the ultra-low temperature refrigerator group, the company should regularly check the pressure controller carefully. Only careful inspection can ensure that the equipment operates within a stable and safe pressure range, and the pressure is stable. The problem will be reduced accordingly.

So, where is the pressure controller? The pressure control unit is installed in different positions and there will be different pressures. The range of settings is different, and the effect on the ultra-low temperature refrigerator group is also different. The principle of high pressure and low pressure is different, and the scope of protection for intelligent ultra-low temperature refrigerators is also different. In actual use, there may be excessive pressure, or the pressure is too small. Naturally, there are some internal causes. If you let it develop, it will have a bad influence on the machinery. At this time, the equipment will be It will be a self-protection method by powering off. By reducing this gap, you can try to make the equipment less problematic and the life will increase accordingly. Therefore, it needs to operate within a very safe pressure range. The technology will run steadily.

For ultra-low temperature refrigerator users, the company should ask technicians to train these personnel to let them know the maintenance expertise, what should be checked, and which conditions should be taken care of.

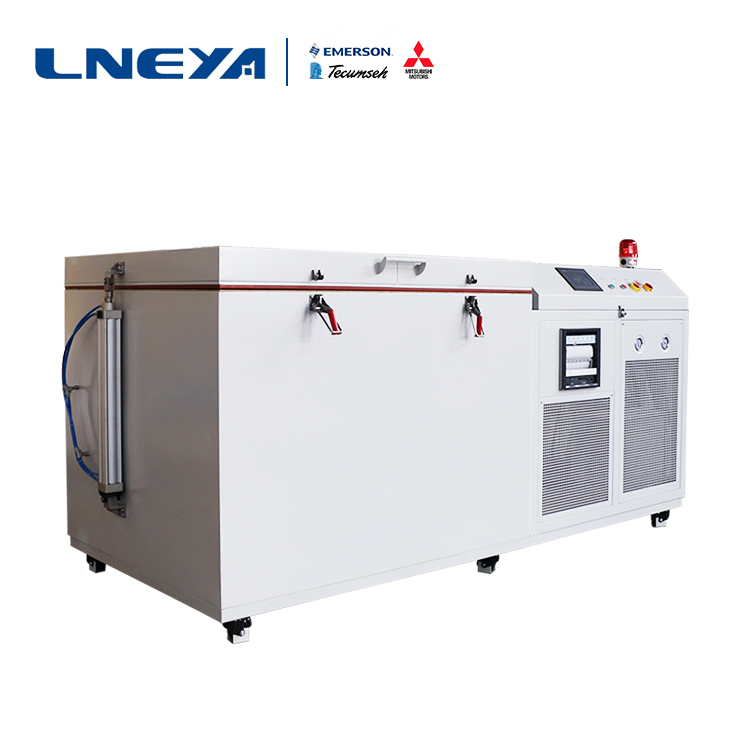

If the relevant configuration of the ultra-low temperature refrigerator is relatively high, the pressure controller failure is relatively small, so it is recommended to choose a reliable manufacturer to purchase.

Recomendaciones relacionadas

-

-

Explosion-proof high and low temperature one machine evaporator use note

1705Each accessory in the explosion-proof high and low temperature integrated machine is more important. Among them, the evaporator has one of the four major accessories, and the refrigeration effect has a certain degree. What are the main choices of ...

Ver detalles -

¿A qué se debe el consumo energético de las unidades de refrigeración de gran tamaño?

1558Durante el funcionamiento de las unidades de refrigeración de gran tamaño, la capacidad de refrigeración y las condiciones de trabajo son los principales problemas de consumo de energía, pero para evitar algunos consumos innecesarios de energía, tenemos que entender claramente. Cuando la ...

Ver detalles -

The Following Works Should Be Done Before Starting Industrial Chillers

16062. For the compressor unit with water system, carefully check whether the cooling water system and chilled water system have water, and whether the water pressure is normal, whether the pipeline system of cooling water and chilled water is unblock...

Ver detalles

LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor