Rapid temperature change test chamber temperature control instructions

The selection of the humidity range of the rapid temperature change test chamber should be noted that the corresponding temperature range should be indicated after the humidity index or the dew point temperature should be given. Because relative humidity is directly related to temperature, for the same moisture content, the higher the temperature, the lower the relative humidity. To achieve high temperature and high humidity, it is only necessary to spray water vapor or atomized water droplets into the air of the cabinet to humidify. Low temperature and low humidity are relatively difficult to control, because the moisture content at this time is very low, and sometimes it is much lower than the moisture content in the atmosphere, and it is necessary to dehumidify the air flowing in the tank to make the air dry.

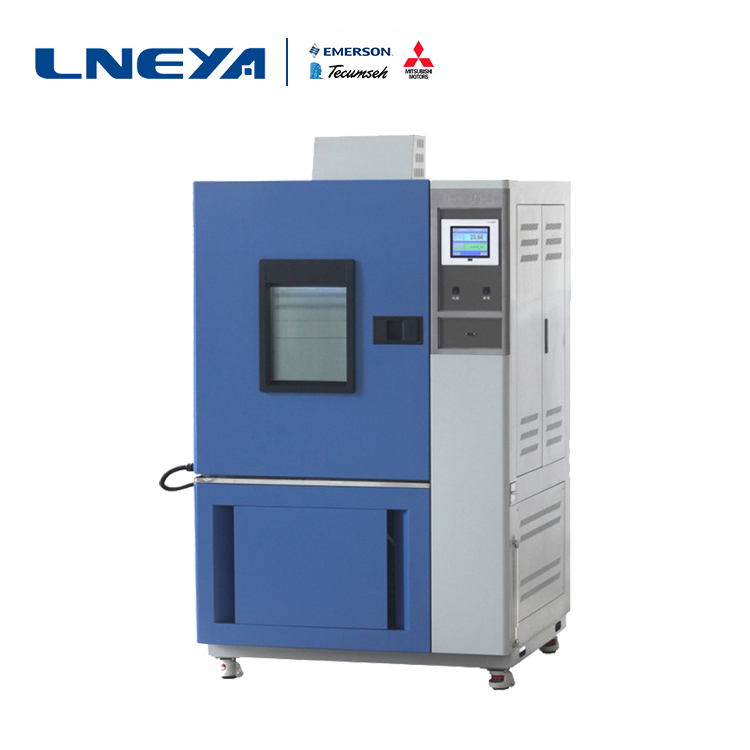

The common rapid temperature change test chamber generally refers to a constant rapid temperature change test chamber, which is controlled by setting a target temperature and the test chamber has the ability to automatically thermostat to the target temperature point. The control method of the constant temperature and humidity test chamber is similar. Set a target temperature and humidity point. The test chamber has the ability to automatically adjust the temperature to the target temperature and humidity point. The high and low temperature alternating test chamber has the program of setting one or more high and low temperature changes and circulations. The test chamber has the ability to complete the test process according to the preset curve, and can control the temperature rise within the range of heating and cooling rate capability. The rate of temperature drop, that is, the temperature rise and temperature drop rate can be controlled according to the slope of the set curve.

Similarly, the high and low temperature alternating heat and humidity test chamber also has a preset temperature and humidity curve, and the ability to control according to presets. Of course, the alternating test chambers all have the function of a constant test chamber, but the manufacturing cost of the alternating test chamber is higher, because the alternating test chamber needs to be equipped with a curve automatic recording device, a program control device, and the test chamber must be solved in the working chamber. When the temperature is high, the refrigerator is turned on. Therefore, the price of the alternating test chamber is generally 20% higher than the price of the constant test chamber. Therefore, we should be realistic and take the test method as the starting point, choose a constant test box or an alternating test chamber.

Different rapid temperature change test chamber manufacturers have different quality, so users need to understand the rapid temperature change test chamber and make more detailed choices.

Recomendaciones relacionadas

-

Explanation Protection for Air Cooled Precision Chiller

1656The places where need air-cooled precision chiller indicate they have high demanding for operating accuracy. Therefore, the protection settings have to work out. Then, which kind of protection for air-cooled precision chiller should be done?Discha...

Ver detalles -

How to deal with the installation of the hot and cold integrated control machine?

1890Since the thermocouple's thermal inertia causes the meter's indicated value to lag behind the measured temperature, this effect is particularly pronounced when performing rapid measurements. Therefore, thermocouples with thinner thermal electrodes...

Ver detalles -

The Inevitable Development Of New Energy Vehicle Battery Test Cooling Device

1412New energy vehicle battery test cooling device The energy crisis and environmental pollution have spawned the development of new energy vehicles. The key to the technology of new energy vehicles is the performance of power batteries. There are man...

Ver detalles -

LED LCD display thermal test system operation process

1588The integrated semiconductor industry has developed rapidly in the past two years, which has driven other industries around it. The chip thermal test system is one of the products. In order to avoid machine failures in the LED liquid crystal displ...

Ver detalles

LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor