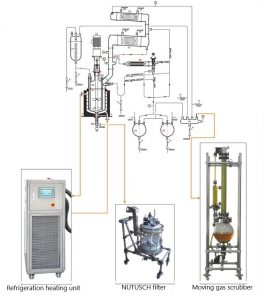

The Role of Chemical Refrigeration Temperature Control Unit

In pharmaceutical and chemical plants, the raw materials inside the reactors involved in industrial production require rapid cooling and cooling. In order to achieve this goal, the reactor undergoes direct refrigeration and cooling, thereby indirectly reducing the temperature of the materials inside the reactor.

1. There should be operational records that record the operation status of the unit, and maintenance technical files should be created. Detailed records are conducive to identifying common faults and hidden dangers, and taking effective measures as soon as possible to prevent faults from occurring.

2. Adopting a compressor, matched with a condenser and evaporator, with high efficiency, stable performance, low noise, and long service life. The centralized control of the PLC unit, equipped with an energy ratio of a compressor, can timely and accurately control the matching of the refrigeration capacity and cooling load of the unit, ensuring efficient operation of the unit and reducing operating costs.

3. The internal integration has multiple protection and processing functions, such as water cut-off, low temperature and high temperature, low voltage anti freezing, phase loss delay start reverse phase, overload motor overheating, and oil pressure difference.

3. Full Chinese operation interface, menu style prompts, and the operation status of the unit can be set arbitrarily. The operating environment is home appliances, and the capacity control can adopt four section or three section and no section control systems.

4. The built-in oil pressure system ensures that the compressor maintains lubrication without the need for an oil pump. The oil separator adopts a double-layer filtration method, which has excellent oil filtering effect. The heat converter can fully utilize its capacity

5. The selection of steel pipes makes the contact between the steel pipes and the fins closer, with higher heat transfer efficiency, small volume, light weight, and more compact and reasonable structure.

Recomendaciones relacionadas

-

Consejos de mantenimiento diario para enfriadoras de recirculación a temperatura ultrabaja?

1504Para garantizar el funcionamiento normal de los enfriadores de recirculación a temperatura ultrabaja después de la puesta en marcha, es necesario asegurarse de que el condensador del enfriador de recirculación a temperatura ultrabaja tenga una buena disipación de calor, de lo contrario la protecci...

Ver detalles -

How to solve the problem of refrigeration pump circulator pump failure?

1724Cooling heating devices are required in many chemical pharmaceutical and laboratory applications. Then how to solve the failure of the refrigeration heating device is also concerned about how to solve it? 1. Circulating pump failure The circulatin...

Ver detalles -

Inspección de compresores y mantenimiento rutinario de enfriadoras de agua pequeñas

1681When people are hungry, they have to eat, and when the machine is broken, of course, it has to be repaired. In daily use, small water cooled chiller requires regular maintenance and other operations. Today, I would like to share with you how to ju...

Ver detalles -

Why do mechanical factories need chillers?

1286There are many reasons why mechanical factories need chillers, and chillers play a very important role in the mechanical processing process, which can improve production efficiency, ensure stable operation of equipment, and extend equipment ...

Ver detalles

LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor