How to save energy in the vacuum chamber refrigeration heating thermostat control unit

In the environment of energy-saving and emission-reduction operation, how to operate the LNEYA vacuum chamber cooling and heating thermostat control unit is very important. Let’s take a look at a few tips to reduce the consumption and see how to use it.

The very important first step in the selection of the vacuum chamber cooling and heating thermostat control unit is that the cooling capacity is too small, which affects the production, and often loses more than the loss; however, the excessive cooling capacity will inevitably increase the cost of the enterprise and cause unnecessary waste. It is recommended that the manufacturer introduce the detailed process in the process of purchasing, and let the professional personnel calculate the appropriate model, the object to be cooled and the time required to reduce the required temperature.

In this process, we must pay attention to some manufacturers to do some small articles on the cooling capacity, often exaggerating the energy efficiency ratio, in fact, these things can pay attention to the greasy ones, there are related data showing the cooling capacity power theoretically. Data, in the actual production process, the cooling capacity will be lower than the theoretical value, according to the actual situation of the environment, the cooling capacity will fluctuate.

The vacuum chamber refrigeration heating constant temperature control unit increases the evaporation temperature under the premise of ensuring the production demand and meeting the safety of the equipment or the product, and appropriately reduces the condensation temperature and increases the flow rate of the cooling tower to ensure the cooling water effect;

Improve regular daily maintenance work, regularly clean the pipeline, reduce pipe resistance and prevent pipe fouling, increase flow, ensure that the evaporator and condenser fully replenish water, enhance heat transfer efficiency, and unclean water source during long-term use. Will produce calcium carbonate and magnesium carbonate deposition pipelines, affecting heat transfer efficiency, increase the power required for the operation of the equipment, so that the electricity costs increase significantly, invisibly increase the cost of the enterprise.

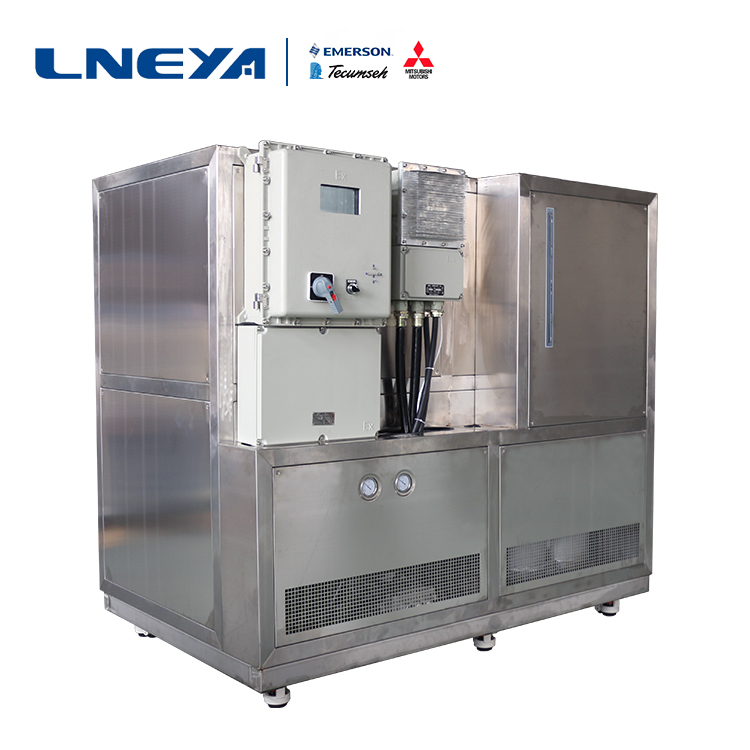

The LNEYA vacuum chamber refrigeration heating constant temperature control unit adopts a fully enclosed pipeline. In the process of operation, the energy consumption ratio can be reduced to a certain extent, so that the vacuum chamber refrigeration heating constant temperature control unit operates efficiently.

Recomendaciones relacionadas

-

Precauciones para adquirir un sistema de control de la temperatura del reactor

1732The reactor temperature control system is applied in the reaction tank for cooling, heating, and temperature control. It has the function of providing low and high temperatures, and can meet the different needs of different customers. Therefore, ...

Ver detalles -

Comprar TCU-Sistema de control de temperatura para refrigeración y calefacción de reactores múltiples

1963Researchers who do research work know that during the laboratory experiments, TCU-multiple reactors are often used for cooling and heating temperature control systems or high and low temperature all-in-one machines, so TCU-multiple reactions that ...

Ver detalles -

Invitation Letter | 10.17-19 Nanjing International Expo Center [5G18]

1934Our company will participate in the 81st APIChina China International Pharmaceutical Raw Material Intermediate Packaging Equipment Exhibition held at Nanjing International Expo Center from October 17-19, 2018. At that time, we will exhibit refrige...

Ver detalles -

Descripción de la temperatura del enfriador de glicol

1599For users and friends, it is necessary tohave a deep understanding of glycol chillers before use. It is recommended toknow the temperature in various equipment such as refrigeration system,evaporating temperature, condensing temperature, etc.If...

Ver detalles

LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor