Description of industrial grade SUNDI heating and cooling temperature control system

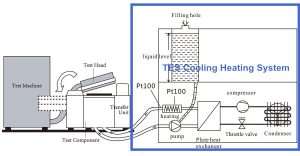

The industrial-grade heating and cooling temperature control system SUNDI series is a device developed and manufactured by LNEYA using its own advantages in the field of cooling, heating and temperature control, and supports customized services in the current technical range and temperature range.

If the industrial kettle heating and cooling temperature control system is used, the temperature can be quickly raised or lowered to reach our set value, and the set value and actual value will be displayed on the panel. The industrial heating and cooling temperature control system heats up very evenly. Generally, the temperature is adjusted using PID self-defined intelligent control, and the temperature control accuracy is 1 ℃, which can better meet the different needs of the product process!

LNEYA’s cooling and heating temperature control system UNDI series can reach 350 ℃, with good thermal stability, dedicated heat transfer oil is not easy to coke and carbon deposit oxidation, combined with the technical experience accumulated in production practice, research and solve the problem in development and design , Manufacturing, installation, operation and repair of theoretical and practical problems in various machinery.

The temperature control of each reactor and reactor requires industrial-grade heating and cooling temperature control systems. The heating system provides accurate temperature control. The SUNDI series uses brand temperature control instruments and uses PID self-tuning intelligent temperature control technology. The control accuracy can reach ± The temperature is around 1 ℃, which can accurately control the use temperature.

The hot oil cooling system can be designed according to user requirements to meet the production process requirements that require rapid cooling after heating. Continuously reduce energy consumption and low operating costs. The heat transfer oil heating system is a liquid-phase closed circuit. The difference between the oil output temperature and the oil return temperature is 20 ℃ -30 ℃, which means that only the temperature difference between 20 ℃ -30 ℃ can reach the operating temperature. It can be customized according to the requirements of different industries, strive to achieve customer-accurate temperature control accuracy, adopt reasonable technical design process, more accurate temperature control, faster heat conduction, high efficiency and energy saving.

Recomendaciones relacionadas

-

Cooling and heating of the reactor and the principle of use

1188Cooling and heating circulator thermostats are commonly used with glass reactors for biochemical instruments. They are widely used in modern fine chemicals, biopharmaceuticals, scientific research and experiment industries. They can be concentrate...

Ver detalles -

Manufacturers of temperature simulation systems for chip testing analyze why chip testing is necessa

1038When users run the chip test temperature simulation system, they need to understand the chip test clearly. For this reason, the manufacturer LNEYA analyzes the relevant knowledge of the chip test and provides you with more detailed knowledge. Func...

Ver detalles -

The significance of temperature in IC testing

1486Every integrated circuit (IC) goes through two type of tests before it can be sold and used to build a product: the first is called a wafer test; the second is called final test. With the improvement of integrated circuit electrical test technolog...

Ver detalles -

Summary of Maintenance Items of Glycol Chiller

1091During the daily operation of glycol chiller, if the maintenance is not in place, the cooling effect of glycol chiller will be reduced. Therefore, in order to improve the operation efficiency of glycol chiller, we suggest that you should carry out...

Ver detalles

LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor