Enfriadores de semiconductores en envases: Aumentar la fiabilidad y el rendimiento

Semiconductor packaging may look like the “final wrap” of the chip, but in reality, packaging is one of the critical steps that determines reliability, performance, and long-term yield.And here’s the catch—packaging is all about managing heat.

Tanto si se trata de pegar alambres como de curar material de relleno o moldear epoxi, el control de la temperatura puede ser decisivo en el proceso. Aquí es donde enfriadores de semiconductores entran en juego. Puede que no sean el centro de atención, pero sin ellos, la mayoría de las líneas de envasado modernas tendrían dificultades para mantener un rendimiento constante.

¿Qué es el envasado de semiconductores?

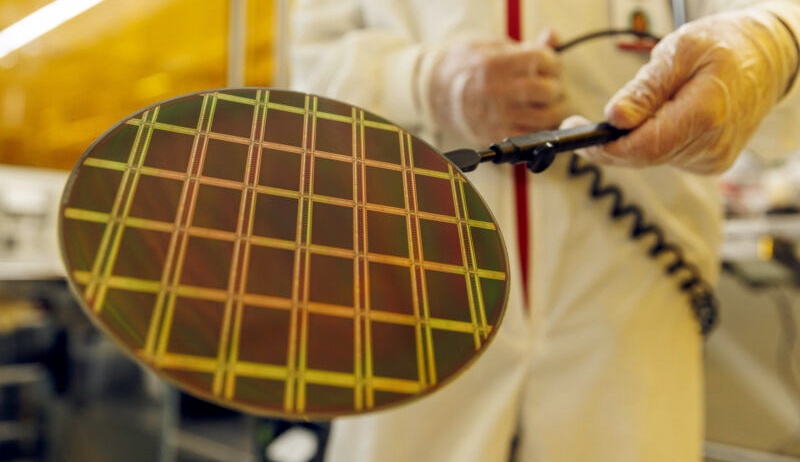

El empaquetado de semiconductores es el paso en el que un troquel de silicio desnudo se convierte en un chip funcional que puede montarse en una placa de circuitos. Es como construir una carcasa protectora al tiempo que se crean las conexiones eléctricas entre la oblea y el mundo exterior.

El envasado abarca una amplia gama de procesos, entre los que se incluyen:

• Die attach – mounting the chip onto a substrate with adhesive or solder.

• Wire bonding or flip chip – making the electrical connections.

• Encapsulation and molding – covering the chip with protective material.

• Final testing and burn-in – ensuring the device works under stress.

Every one of these steps relies on precise thermal conditions. A little too hot, and materials expand, warp, or crack. Too cold, and adhesives won’t cure properly, and bond strength drops. That’s why fabs invest so heavily in environmental control systems. Packaging is not just about “sealing” the chip—it’s about controlling energy transfer at microscopic levels.

Retos de temperatura en el envasado de semiconductores

If you ask any packaging engineer what keeps them up at night, chances are the answer is “thermal management.” El calor aparece de forma inesperada.

Fijación de troqueles

Por ejemplo, la fijación de chips. Fijar un chip con epoxi parece bastante sencillo, pero el adhesivo tiene un perfil de temperatura muy específico. Si el calentamiento es desigual, se forman pequeños huecos en el interior de la unión. Esos huecos se convierten más tarde en puntos de fallo cuando el chip se calienta durante el funcionamiento en el mundo real.

Unión de cables

La unión de cables es otro proceso delicado. Cuando se unen alambres de oro o cobre a almohadillas de aluminio, la interfaz necesita el calor justo para crear una unión fiable. Si se calienta demasiado, la almohadilla se despega. Demasiado poco, y la unión no se mantendrá durante los ciclos térmicos.

Embalaje de Flip Chip

El empaquetado de flip chips añade aún más complejidad. Los puntos de soldadura por reflujo son extremadamente sensibles a las velocidades de calentamiento y enfriamiento. Un enfriamiento demasiado rápido puede provocar tensiones en los cordones, mientras que un enfriamiento demasiado lento puede provocar uniones irregulares.

Moldeado y encapsulado

Y luego están el moldeo y el encapsulado. Las resinas epoxi se curan mediante reacciones exotérmicas. Al endurecerse, liberan calor. Si ese calor no se retira con la suficiente rapidez, la resina se endurece de forma desigual, lo que provoca tensiones internas y deformaciones en el envase. Incluso una ligera curvatura en un envase puede impedir que se monte correctamente en una placa de circuito.

Estos retos explican por qué las instalaciones de envasado necesitan algo mucho más preciso: herramientas que puedan mantener la temperatura de los líquidos en fracciones de grado, 24 horas al día, 7 días a la semana.

Why Semiconductor Chillers Are Essential in Packaging?

This is where semiconductor chillers prove their value. They don’t just “cool things down.” En proporcionan un control de la temperatura estricto, repetible y fiable en múltiples etapas de envasado.

Temperatura estable para la fijación de troqueles

Durante la fijación de troqueles, ya sea con epoxi de plata o soldadura, la fase de pegado requiere unas condiciones térmicas constantes. Un enfriador de semiconductores garantiza que el adhesivo se cure a la velocidad y con la uniformidad adecuadas.

Esto reduce el riesgo de huecos y mejora la fiabilidad del dispositivo a largo plazo. En el caso de los chips de alta potencia, en los que la calidad de la fijación de la matriz influye directamente en la resistencia térmica, el papel del refrigerador es aún más crítico.

Precisión en los procesos de wire bonding y flip chip

Las máquinas de encolado son sensibles a las más mínimas variaciones de temperatura. El husillo, el capilar de unión y la platina se dilatan cuando se calientan. Un refrigerador evita esta desviación manteniendo la chilled water o líquido escénico a una temperatura estable. En flip chip, los enfriadores de semiconductores regulan los perfiles de reflujo y mantienen rampas de enfriamiento que protegen las juntas de soldadura de las grietas.

Enfriamiento durante el moldeo y la encapsulación

En el moldeo, un enfriador elimina el exceso de calor generado por el curado del epoxi. Sin una refrigeración precisa, los envases pueden deformarse o presentar grietas internas. Los enfriadores permiten que las prensas de moldes funcionen de forma más rápida y uniforme, ya que la fase de enfriamiento se vuelve predecible y repetible. Esto no sólo ahorra tiempo de ciclo, sino que también mejora la planitud del envase.

Apoyo a las pruebas de fiabilidad

Tras el embalaje, los chips se someten a pruebas de fiabilidad, como ciclos térmicos, pruebas de quemado o pruebas de sesgo de humedad. Muchas de ellas requieren cambios rápidos de temperatura. Los refrigeradores se integran con las cámaras térmicas para proporcionar condiciones estables y repetibles, garantizando que los resultados de las pruebas reflejen el rendimiento real del producto.

Invertir en un enfriador de semiconductores fiable

Heat is both necessary and dangerous—it enables bonding and curing but threatens yield if uncontrolled. Refrigeradores de semiconductores dan a las fábricas la estabilidad necesaria para gestionar este equilibrio.

Estabilizan la fijación de las matrices, mantienen la precisión de la unión, extraen el calor de los procesos de moldeo y soportan pruebas de fiabilidad críticas. Además, ayudan a las fábricas a proteger su inversión en obleas y equipos, al tiempo que garantizan que los productos lleguen al mercado sin debilidades ocultas.

Póngase en contacto con nuestro equipo hoy mismo para estudiar soluciones de refrigeración personalizadas para su fábrica.

- What Does a 200 Ton Chiller Cost

- Temperature Control in Photolithography

- Is a Used Chiller a Good Idea

- Chiller Components and Refrigeration Fundamentals Guides

- Chiller Types and Selection Guides

- How Does a Peltier Cooler Work

- Peltier Chiller vs. Compressor Chiller

- What Is a Peltier Chiller

- diciembre 2025

- noviembre 2025

- octubre 2025

- septiembre 2025

- agosto 2025

- julio 2025

- junio 2025

- mayo 2025

- marzo 2025

- febrero 2025

- enero 2025

- diciembre 2024

- noviembre 2024

- octubre 2024

- septiembre 2024

- agosto 2024

- julio 2024

- junio 2024

- mayo 2024

- abril 2024

- marzo 2024

- febrero 2024

- septiembre 2023

- julio 2023

- junio 2023

- mayo 2023

- enero 2023

refrigerador por aire enfriadora Instalación de enfriadoras Chiller Maintenance chiller refrigerant refrigeradores Montaje en frío Congelador enfriador de refrigeración refrigeración calefacción cooling system sistema dinámico de control de la temperatura chiller de bajo consumo energético enfriador a prueba de explosiones congelador circulador de calefacción enfriadora industrial enfriadoras industriales refrigeración industrial congelador industrial frigorífico industrial reactor de camisa refrigerador de laboratorio refrigerador de baja temperatura noticias enfriador de aceite enfriador de proceso enfriamiento de procesos reactor enfriador refrigeración del reactor refrigeración del reactor calefacción reactor calefacción refrigeración circulador refrigerado refrigerador de tornillo enfriador de semiconductores enfriador de pruebas de semiconductores sundi tcu control de temperatura cámara de pruebas termostato refrigerador de ultra baja temperatura enfriador de pruebas de vehículos enfriador de agua refrigerador por agua

Enfriadores relacionados

CONTÁCTANOS

TEL:

EMAIL:

WeChat & WhatsApp:

Wechat QR

¿Tiene alguna pregunta o necesita un presupuesto? Complete el formulario a continuación y nuestro equipo se pondrá en contacto con usted en 24 horas.

LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor