Noticias

Todo el análisis del proceso de cambio de refrigerante de la unidad enfriadora industrial

Refrigerant is an indispensable part of the refrigeration system of the industrial chiller. During the operation of the industrial refrigeration unit, the refrigerant constantly changes in the industrial refrigeration unit to achieve the cooling effect, so what changes have occurred in the industrial refrigeration unit refrigerant! Let me introduce you to the process of refrigerant changes in industrial refrigeration units. What are the relevant contents? Refrigerant change process of industr...

Ver detalles

¿Cómo resolver las averías más comunes de las enfriadoras industriales de circulación?

For industrial circulating chillers, if they are always in a high-temperature operating state, a large amount of cold air will be seriously lost. After ensuring the sealing effect of the use environment, effective thermal insulation can be carried out for the industrial chiller in a timely manner to ensure that the industrial circulating chiller is in a stable operating state. Stable operating efficiency can increase the efficiency of lowering the temperature in the unit environment and reduc...

Ver detalles

Solvent description and installation of distillation cooling equipment

During the chemical reaction, most of the chemical reactions are carried out in solvents. Solvent is an important medium, which can make all kinds of molecules participating in the reaction evenly distributed, increase the chance of collision and contact between molecules, and accelerate the progress of the reaction. The solvent can conduct heat, through which it can provide heat to the reaction substance, and promote the progress of the reaction; through it, it can also transfer the heat rel...

Ver detalles

La existencia de la destilación y el control de temp. durante la destilación-SUNDI control dinámico de temp.

Distillation exists in industries such as biopharmaceutical and petrochemical industries. Laboratory distillation includes vacuum distillation, short-path distillation, thin-film distillation, steam distillation, batch distillation, azeotropic distillation, industrial distillation (multi-effect distillation), etc. Then, temperature control must be performed in the distillation treatment step. However, temperature control is only one of many process variables in pressure, flow rate and composi...

Ver detalles

Benefits of Winterizing and Degassing Prior to Distillation

Prior to distilling oil, you should follow a winterization and degassing procedure. The winterization will remove fats, waxes, and other inactive and unwanted compounds. Degassing will remove any solvents and other inactives with low boiling points to prevent foaming during distillation. These processes are imperative to successful distillation and could be considered more important than the actual distillation itself. Always use safety equipment and have proper ventilation when working with ...

Ver detalles

Efecto del ciclo de temperatura de enfriamiento y calentamiento durante la emulsificación

Emulsification is the effect of a liquid in which even tiny droplets are evenly dispersed in another liquid that is incompatible with each other. Emulsification is a liquid-liquid interface phenomenon. Two immiscible liquids, such as oil and water, are divided into two layers in a container. Oil with a lower density is in the upper layer, and water with a higher density is in the lower layer. If an appropriate surfactant is added and the mixture is vigorously stirred, the oil is dispersed in ...

Ver detalles

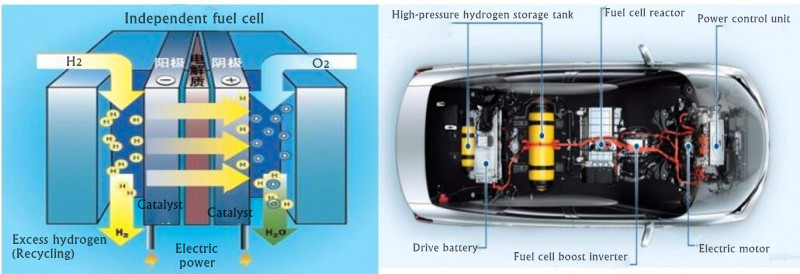

Sistema de simulación de refrigeración para pruebas de rendimiento extremo de baterías

With the development of technology, pure electric vehicles are becoming more and more common, but pure electric vehicles are difficult to get a better solution in terms of cruising range, charging speed, and pollution after battery waste. This makes scientific research workers and related companies in various countries The ideal goal of using energy is to turn to proton exchange membrane fuel cells, thus carrying out a lot of scientific research and real car experiments. In order to improve t...

Ver detalles

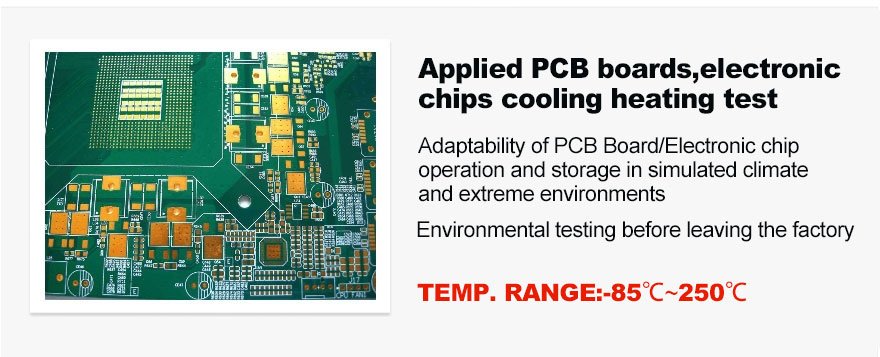

Temperature control of integrated circuit/chip wafer quality and reliability test items

The most basic part of making a chip is design-tape-package-test. The chip cost structure is generally 20% of labor cost, 40% of tape, 35% of package, and 5% of test. The test is actually the most in all aspects of the chip. "Cheap" step, but the test is the final level of product quality. If there is no good test, the product PPM [Million Failure Rate] is too high, and the return or compensation is far from 5% of the cost. What tests do chips need to do?There are three main categories: chi...

Ver detalles

¿Qué es el VCSEL en la prueba de quemado de chips? ¿Qué efecto tiene la temperatura?

The full name of VCSEL is Vertical-cavity Surface-emitting Laser, the Chinese name is vertical cavity surface emitting laser. It is a kind of semiconductor laser. Semiconductor lasers are lasers manufactured using semiconductor manufacturing technology. Like all semiconductor-manufactured devices, semiconductor lasers have smaller size, lighter weight, lower power consumption, higher reliability, and longer lifespan than solid, gas, and liquid lasers. Features. Semiconductor lasers are divide...

Ver detalles

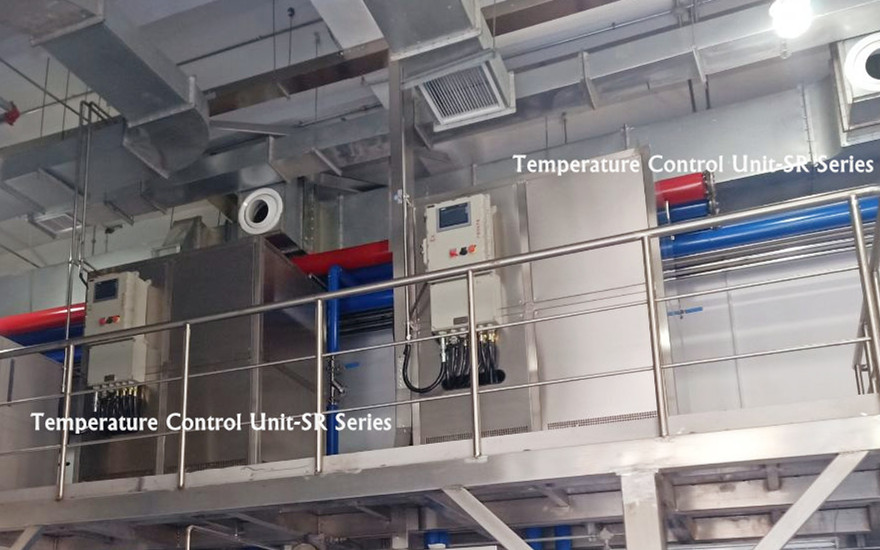

Unidad de control de la temperatura necesaria para la extracción de materias primas químicas de la medicina china-TCU

The production process of traditional Chinese medicine raw materials is relatively complicated: long process, many pipelines, and complicated operations; and most of the preparation raw materials are unstable, such as high environmental parameters such as temperature, humidity, and light, and related raw materials are mostly flammable and explosive. Unlike the preparation product process, the production process of traditional Chinese medicine raw materials is mostly a cross-fusion process of ...

Ver detalles LNEYA Industrial Chillers Manufacturer

LNEYA Industrial Chillers Manufacturer