Noticias

Description of industrial grade SUNDI heating and cooling temperature control system

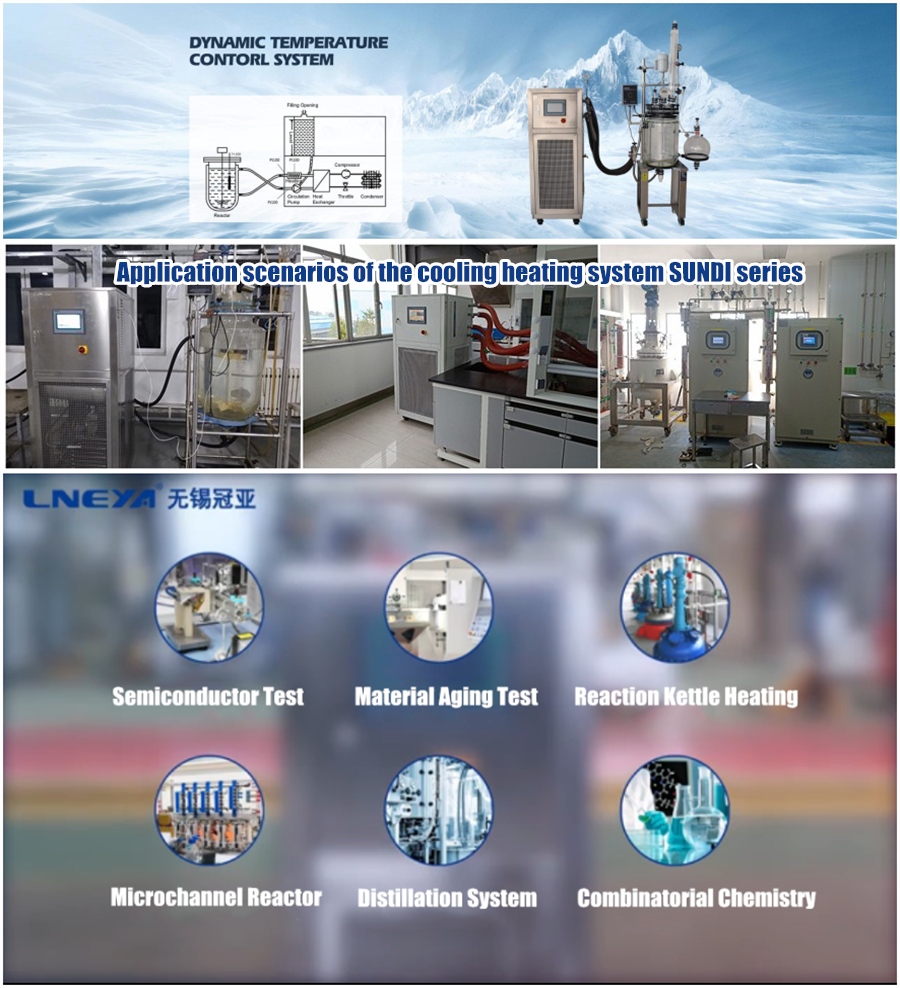

The industrial-grade heating and cooling temperature control system SUNDI series is a device developed and manufactured by LNEYA using its own advantages in the field of cooling, heating and temperature control, and supports customized services in the current technical range and temperature range. If the industrial kettle heating and cooling temperature control system is used, the temperature can be quickly raised or lowered to reach our set value, and the set value and actual value will be d...

Ver detalles

Failure Analysis of Ultra Low Temperature Chiller Supporting Distillation Equipment

Once the freezer used in the matching distillation equipment fails, we need to solve it in a timely and effective manner to avoid affecting the operation of the entire experiment. In the pharmaceutical, chemical and other industries, low temperature freezers are common equipment and provide a reliable guarantee for various low temperature environments such as pharmaceuticals. In recent years, with the continuous development of the pharmaceutical industry and the continuous improvement of requ...

Ver detalles

Comprar TCU-Sistema de control de temperatura para refrigeración y calefacción de reactores múltiples

Researchers who do research work know that during the laboratory experiments, TCU-multiple reactors are often used for cooling and heating temperature control systems or high and low temperature all-in-one machines, so TCU-multiple reactions that can provide cold or heat The cooling and heating temperature control system of the kettle has become indispensable. Generally, the cooling and heating temperature control system of the TCU-multiple reaction kettle is used to cool down or constant tem...

Ver detalles

Unidad de control de la temperatura del reactor TCU con bucle de control PID

LNEYA reaction kettle temperature control unit tcu adopts PID control loop, which has certain applications in many fields. The reaction kettle temperature control unit tcu of PID control loop adopts fully closed cycle refrigeration system, with fast cooling and heating speed and low noise.The reaction tank temperature control unit tcu of the PID control loop can achieve a dynamic temperature control of -120 degrees to 300 degrees. The system uses existing thermal energy (such as steam, coolin...

Ver detallesSUNDI Sistema de refrigeración y calefacción Pruebas de I+D de materiales sintéticos orgánicos y química fina

LNEYA's customer is a research institute engaged in the research, development and production of high-performance, environmentally-friendly new organic materials and fine chemicals.The adhesives produced by customers can be used in integrated circuits, quartz crystals, printed circuit boards, etc .; engineering plastics are used in aerospace, electronics and electrical, precision machinery, office automation equipment, instruments and meters. One of the characteristics of the product is high t...

Ver detalles

Control method for semiconductor test chiller to meet temperature requirements

The biopharmaceutical field requires high-precision temperature to control the activity of enzymes and the production of products; the chemical industry field requires specific temperatures to make chemical reactions proceed stably; the electronics manufacturing field needs to provide a constant temperature environment for various electronic components to make them stable Work and achieve better performance, such as: quartz crystal oscillator, electronic linear accelerator, etc. Although ther...

Ver detalles

Uso de refrigeradores de tratamiento en frío para piezas mecánicas y comparación con el nitrógeno líquido

In the machinery manufacturing industry, the quality requirements for parts are very strict. In order to better improve the performance of machinery, improve product quality and life, a new technology-cryogenic treatment has been produced. During the cryogenic treatment, the retained austenite in the parts can be largely converted to martensite, which can enhance the wear resistance, strength, toughness and impact resistance of the parts materials, improve fatigue strength and eliminate Inter...

Ver detalles

The necessity of temperature heating and cooling cycle in the process of catalytic hydrogenation

In recent years, with the rising price of oil, the demand for benzene obtained from coking benzene has increased, coupled with the country's increasing emphasis on environmental protection, the widespread application of coking benzene hydrogenation technology is imperative. According to the reaction temperature, the coking crude benzene catalytic hydrogenation process can be divided into three types: high temperature hydrogenation (600℃~ 630℃), intermediate temperature hydrogenation (480℃~ 55...

Ver detalles

Consejos para ahorrar energía en las empresas que utilizan enfriadoras industriales

Nowadays, energy conservation has been advocated, and power consumption has always been a concern for everyone. Everyone knows that industrial equipment consumes electricity. For many chemical material manufacturing enterprises, the pressure of the chiller's power consumption is not small, so how to save power is the core of this article! Power-saving tips for industrial chiller: First, avoid and reduce the scale of industrial chiller pipeline If the sewage treatment is not done well, calcium...

Ver detalles

Introducción del principio de destilación y del dispositivo de control del ciclo de temperatura

Distillation is a common method for purifying liquid substances and separating mixtures. The boiling point of the compound can also be measured by distillation, so it also has a certain significance for the identification of pure liquid organic compounds. The change of saturated vapor pressure of a substance at different temperatures is the basis of distillation separation. Heating the liquid to boiling makes the liquid into a vapor, and then the vapor is cooled and then condensed into a liqu...

Ver detalles LNEYA Industrial Chillers Manufacturer

LNEYA Industrial Chillers Manufacturer