Various reactors and materials use PLC temperature control system

The PLC temperature control system is used for the lifting and constant temperature control of glass reactors, metal reactors and bioreactors, especially for heat exothermic control in the reaction process. The heat transfer oil in the jacket of the reactor is heated, and the heat energy is indirectly transferred to the heating kettle in the material, so as to control the heating temperature of the reaction material. The industrial temperature control technology of the equipment has the advantages of high temperature control accuracy, fast heat conduction speed, energy saving, etc. Features.

1. Adopt imported microcomputer or PLC control, pipeline explosion-proof device; air blowing and oil return functions.

2. The oil return temperature indicator has automatic exhaust function when it is started.

3. Heating power switching function.

4. Negative pressure system pressure operation, instant cooling and start function.

5. The isolated electrical control box prolongs the service life of electrical appliances.

6. Realize automatic management; multi-point temperature control unit can be customized, and oil pump horsepower and heating power can be customized.

7. Stainless steel integrated pipeline can reduce pipeline resistance and rust;

8. The PLC temperature control system has the advantages of large temperature control range, good thermal certainty, compact structure, fast temperature rise and fall, and accurate temperature control.

9. The equipment uses the same medium to ensure the system, and there is no danger of water dissolving into the heat transfer oil and causing explosion during the heating process. Multiple heating protections also safeguard the system.

The PLC temperature control system requires users to do regular maintenance work, so as to effectively avoid failures and delay the service life of the equipment, but under the premise that the equipment is of good quality, all the manufacturers and after-sales Teams are also more important.

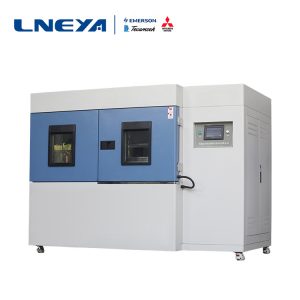

Our LNEYA PLC temperature control system includes SUNDI series UST series dynamic temperature control system, TCU secondary heat exchange system ZLF and SR series.

Recomendaciones relacionadas

-

Maintenance of vacuum pump for fully enclosed heating and cooling circulator

1759Each accessory in the fully enclosed heating and cooling circulator constitutes the entire refrigeration heating and temperature control system. The performance of the pump is also very important. How to make the maintenance of the pump? For the f...

Ver detalles -

Maintenance method of minus 17 ° C ultra-low temperature refrigerator

1732After the long-term use of the ultra-low temperature refrigerator of minus 17 °C, it is necessary to carry out certain maintenance work. If the user does not know how to carry out the maintenance work, you can contact the manufacturer to obtain th...

Ver detalles -

Treatment of insufficient exhaust gas in high and low temperature impact test chamber compressor

1825The efficiency of the high and low temperature impact test chamber during use is very important. If there is a shortage of high compressor exhaust, we need our LNEYA technicians to solve it in time. So, how to solve it better? The high and low tem...

Ver detalles -

LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor