How to protect the zero-86 degree low temperature refrigerator?

The structure of the scroll compressor and the piston compressor in the low-to-86 degree low-temperature refrigerator is different, and it cannot be reversed. The reverse phase of the three-phase power supply of the low-zero-86 degree low-temperature refrigerator will cause the compressor to reverse, so it is necessary to install reverse phase protection. To prevent the refrigeration press from reversing. After the reverse phase protector is installed, the compressor can be operated in the normal phase and does not operate in the reverse phase. When the sub-zero-86 degree low temperature refrigerator is reversed, just reverse the two lines of the power supply and change to the normal phase.

In order to protect the compressor under high load operation or insufficient refrigerant, an exhaust temperature protector needs to be installed in the subzero-86 degree low temperature refrigerator system, and the exhaust gas temperature is set within the range of 130±5°C. The compressor is stopped. This temperature value refers to the position detection temperature of the compressor exhaust pipe within 10 cm from the outlet.

In order to protect the operation of the subzero-86 degree low temperature refrigerator compressor when the refrigerant is insufficient, a low pressure switch is required. When the temperature is set to 0.03 mpa or more, the compressor stops running. Zero-to-86 degree low-temperature refrigerator compressors operate in the state of insufficient refrigerant, then the temperature of the compressor part and the motor part of the sub–86 degree low-temperature refrigerator will rise instantaneously. At this time, the low-voltage switch of the lower-86 degree low-temperature refrigerator can be Protection against damage to the compressor and motor burnout that cannot be protected by the internal temperature and exhaust temperature protectors.

In order to prevent the zero-to-86 degree low-temperature refrigerator from running 24 hours, the high-load operation of the lower-86 degree low temperature refrigerator compressor, the electromagnetic switch is poor, the overcurrent caused by the holding shaft, or the motor is burnt due to the motor temperature. The internal thermostat is installed inside the compressor. It is installed on the neutral contact of the three-phase motor. When the subzero-86 degree low temperature refrigerator is abnormal, the motor is protected by cutting off the three phases at the same time.

The zero-to-86 degree low-temperature refrigerator electromagnetic switch is used to control the compressor operation of the zero-86 degree low-temperature refrigerator. The shutter is closed for the purpose of installation. When installing, it should be kept vertical. If the installation is wrong, the joint spring pressure will change and noise will be generated. It causes phase loss operation. For models with a compressor with a direct power failure protector, there is no need to load the protector.

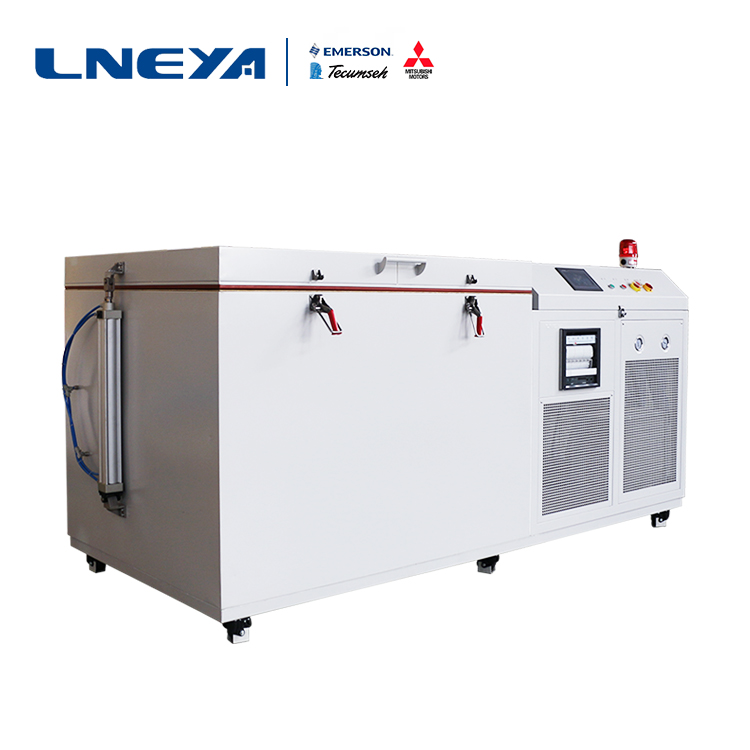

The protection device of the minus-86 degree low temperature refrigerator is very necessary. All the users are advised to choose the time, if it is capable, Wuxi Guanya LNEYA recommends the explosion-proof zero-86 degree low temperature refrigerator.

Recomendaciones relacionadas

-

Descripción de la presión del refrigerador específico de laboratorio

1584The laboratory-specific chiller is one of the more popular equipments in the mechanical equipment industry. For this reason, the relevant pressure instructions have been specially compiled to help you better understand the laboratory-specific chil...

Ver detalles -

Unidad de enfriamiento a baja temperatura en la producción de materiales auxiliares para catalizadores PGA

1273Los refrigeradores de baja temperatura desempeñan un papel importante en el proceso de reacción de producción del ácido poliglicólico (PGA) y sus catalizadores y aditivos. El proceso de síntesis y postratamiento del ácido poliglicólico suele implicar reacciones exotérmicas,...

Ver detalles -

Puesta en servicio de equipos de refrigeración por agua circulante en la industria química

1643Después de completar la instalación de enfriadoras de agua circulante en la industria química, es necesario llevar a cabo ciertas depuraciones en la fase inicial de funcionamiento. Sólo a través de una depuración cuidadosa podemos averiguar si hay problemas ocult...

Ver detalles -

How To Solve The Electric Vehicle Motor Test Condensation Is Too High?

1794The condensing pressure of the electric vehicle motor test will increase, the compression function will increase, the cooling capacity will decrease, the cooling coefficient will decrease, and the energy consumption will increase. The reason for t...

Ver detalles

LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor