Refrigeración Calentamiento del reactor y del material

SUNDI -25℃~300℃- Capacidad de enfriamiento1kW~200kW

- Potencia calorífica2,5 kW~200 kW

- Gama de potencia4kW~260kW

- Precisión media±0.5℃~±1℃

- Precisión del material±1℃~±1.5℃

- RefrigeranteR404A/R507C

- Peso130KG~2250KG

Descripción del producto

● Working temperatures from -120°C to +350°C

● Previously unachievable performance

●Intelligent temperature control

● Maximum process stability and reproducibility

● Adop plate heat exchager, Pipeline heating, the fastest heating and cooling rates.

● High cooling power from 0.5 to 1200kW

● Large temperature range without fluid change

● Closed system, extend thermal fluid lifetime

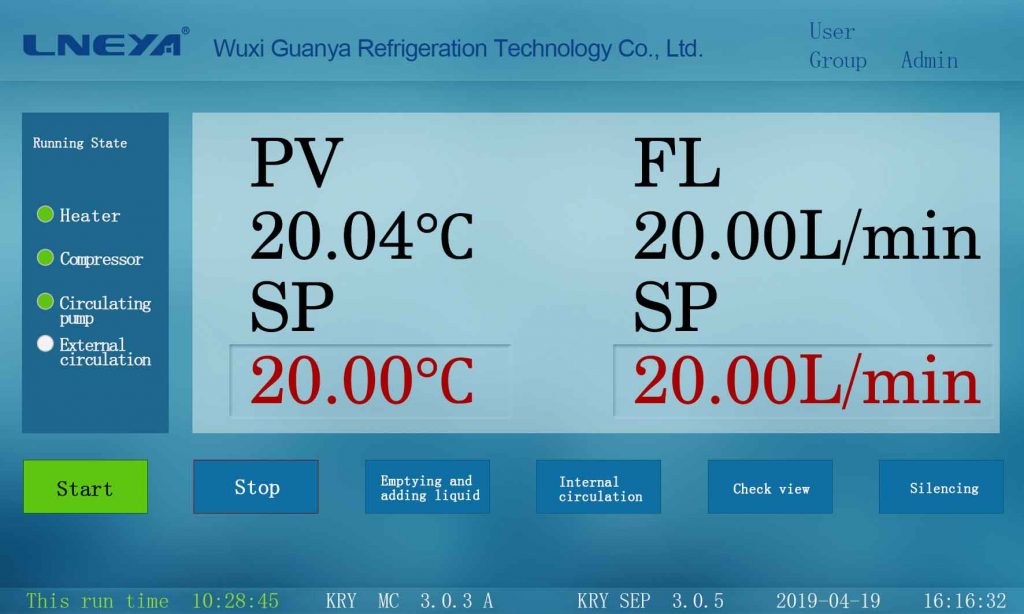

● 7-inch, 10-inch color TFT touch screen display

● Comprehensive warning and safety functions

● Rapid cooling down from high temperature (from 300 °C)

● Use magnetic drive pump, solve the circulation pump leakage

Detalles de configuración

| Modelo | SUNDI -225V SUNDI -225WV |

SUNDI -235V SUNDI -235WV |

SUNDI -255V SUNDI -255WV |

SUNDI -275V SUNDI -275WV |

SUNDI -2A10V SUNDI -2A10WV |

SUNDI -2A15V SUNDI -2A15WV |

SUNDI -2A25V SUNDI -2A25WV |

SUNDI -2A38WV |

SUNDI -2A60WV |

SUNDI -2A95WV |

SUNDI -2A130WV |

SUNDI -2A200WV |

|

| Rango temp. | -25℃~+300℃ | ||||||||||||

| Modo de control | Retroalimentación PID + Nuestro cálculo especial de control dinámico, controlador PLC | ||||||||||||

| Control temp. | Modelo de control de temp. de proceso y temp. de camisa | ||||||||||||

| Diferencia temp. | Ajustar o controlar la diferencia de temperatura entre el aceite de la camisa y el proceso de la materia prima | ||||||||||||

| Editor de programas | 5 programas, cada programa puede editar 40 pasos. | ||||||||||||

| Comunicación Portocolo |

MODBUS RTU Protocol, RS485 interface | ||||||||||||

| Material temp. comentarios |

PT100 OR 4~20mA or communication(normal: PT100) | ||||||||||||

| Retroalimentación temp. | La temperatura de tres puntos: la entrada y la salida del equipo, la temperatura del material del reactor (sensor de temperatura externo). | ||||||||||||

| Medium temp. precisión |

±0.5℃ | ||||||||||||

| Material temp. precisión |

±1℃ | ||||||||||||

| Heating power kW | 2.5 | 3.5 | 5.5 | 7.5 | 10 | 15 | 25 | 38 | 60 | 95 | 130 | 200 | |

| Refrigeración capacidad kW a |

300℃ | 2.5 | 3.5 | 5.5 | 7.5 | 10 | 15 | 25 | 38 | 60 | 95 | 130 | 200 |

| 100℃ | 2.5 | 3.5 | 5.5 | 7.5 | 10 | 15 | 25 | 38 | 60 | 95 | 130 | 200 | |

| 50℃ | 2.5 | 3.5 | 5.5 | 7.5 | 10 | 15 | 25 | 38 | 60 | 95 | 130 | 200 | |

| 20℃ | 2.5 | 3.5 | 5.5 | 7.5 | 10 | 15 | 25 | 38 | 60 | 95 | 130 | 200 | |

| -5℃ | 2 | 3 | 4.5 | 6.6 | 8 | 12 | 19 | 30 | 46 | 70 | 80 | 125 | |

| -20℃ | 1 | 1.8 | 2.8 | 3.8 | 4.6 | 7 | 12 | 16 | 22 | 32 | 43 | 65 | |

| Circulación pump max L/min bar |

20 | 35 | 35 | 50 | 60 | 110 | 150 | 150 | 250 | 400 | 400 | 600 | |

| 1.2 | 1.2 | 1.2 | 1.2 | 1.5 | 1.5 | 1.5 | 1.5 | 2.5 | 2.5 | 2.5 | 2.5 | ||

| Bomba | magnetic drive pump | ||||||||||||

| Compresor | Mitsubishi | Emerson copeland vortex flexible | Dorin seni-closed compressor | ||||||||||

| Válvula de expansión | Electronic expansion valve | ||||||||||||

| Evaporador | Intercambiador de placas | ||||||||||||

| Panel de control | 7-inch touch screen,show temp curve\EXCEL data output | ||||||||||||

| Protección de seguridad | Self-diagnosis function; freezer overload protection; high pressure switch, overload relay,thermal protection device, liquid low level protection, high temperature protection and temperature fault protection. |

||||||||||||

| Closed circulation sistema |

The whole system is full closed circulation, there is no oil mist at high temperature and no water vapor at low temperature, pressure do not rise up when system is running. The system will supply oil automatically at low temperature. |

||||||||||||

| Refrigerante | R404A/R507C, optional: R448A | ||||||||||||

| Tamaño de la conexión | ZG1/2 | ZG3/4 | ZG3/4 | ZG1 | ZG1 | ZG1 | DN32 | DN40 | DN50 | DN65 | DN65 | DN80 | |

| Refrigeración por agua type W(@20℃) |

600 L/H |

800 L/H |

1200 L/H |

1600 L/H |

2400 L/H |

3000 L/H |

6 m³/H |

10 m³/H |

12 m³/H |

18 m³/H |

24 m³/H |

36 m³/H |

|

| Dimensión (water type)cm |

40 *70 *130 |

45 *70 *160 |

55 *70 *175 |

55 *70 *175 |

70 *85 *185 |

80 *120 *185 |

80 *120 *185 |

100 *150 *185 |

200 *145 *205 |

200 *145 *205 |

250 *145 *225 |

300 *160 *225 |

|

| Peso en kg | 130 | 180 | 195 | 260 | 320 | 390 | 620 | 820 | 1100 | 1350 | 1680 | 2250 | |

| Potencia 380V 50HZ | 4kW | 6kW | 8kW | 11 kW | 14 kW | 21kW | 34 kW | 52kW | 79 kW | 123 kW | 165 kW | 260 kW | |

Principio de funcionamiento

Ultra high temperature cooling technology can directly cool from a high temperature of 300℃[because only the heat transfer medium in the expansion chamber contacts with oxygen in the air (and the temperature of the expansion tank is between normal temperature and 60℃), which can reduce the risk of heat transfer medium being oxidized and absorbing water in the air. At high temperature, no heat conducting medium evaporates, and continuous temperature control of – 80℃ ~ 190℃, – 70℃ ~ 220℃, – 88℃ ~ 170℃, – 55℃ ~ 250℃ and – 30℃ ~ 300℃ can be realized without pressurization.

Aplicaciones: Diversos Reactores (Microcanales, Vidrio, Reactores Encamisados, etc.), Sistema de Destilación o Extracción, Laboratorio, Universidad, Instituto de Investigación, Aeroespacial, Industria Automotriz, Semiconductores y Pruebas Eléctricas, Química, Farmacéutica, Petroquímica, Bioquímica, Médica, Hospitalaria, Taller de I&D, Aeroespacial, Biológica y Otras Industrias.

Displays Various Information:

1. Muestra todos los tipos de temperaturas de control del proceso.

2. Muestra el nivel de líquido del medio conductor del calor en el vaso de expansión.

3. Indicación de funcionamiento del sistema de refrigeración.

4. Muestra la indicación de funcionamiento del calentador.

5. Muestra la indicación de funcionamiento de la bomba de circulación.

6. Muestra el control de temp. ( patrón de control de temp. de materiales, control de temp. media conductora de calor ).

7. Se puede ajustar el control del límite superior e inferior de la temperatura.

8. Se puede ajustar la diferencia de temperatura entre la camisa y el material del reactor.

9. Muestra la alarma para añadir el líquido cuando está vacío.

10. El compresor frigorífico puede funcionar de forma manual o automática.

También pueden interesarle estos productos

Serie de conversión de frecuencia SUNDI Z

Serie de conversión de frecuencia SUNDI Z

WHATSAPP WECHAT Ultra high temperature cooling technology can directly cool from a high temperature of 300℃[because only the heat transfer medium in the expansion…

SUNDI -10℃~150℃

SUNDI -10℃~150℃

Fully enclosed system, single medium completes refrigeration and heating -120~350℃ ±0.5℃ AC 380V 50HZ 8kW max Ultra high temperature cooling technology can directly cool from a hi…

SUNDI -80℃~250℃

SUNDI -80℃~250℃

● Working temperatures from -120°C to +350°C ● Previously unachievable performance ●Intelligent temperature control ● Maximum process stability and reproducibility ● Adop plate heat exchager, Pipeline heating, the fastest he…

SUNDI-320/320W

SUNDI-320/320W

Fully enclosed system, single medium completes refrigeration and heating -120~350℃ ±0.5℃ Ultra-high Temperature Cooling Technology Can Directly Cool Down From 300℃ High Temperature. Bec…

SUNDI -25℃~200℃

SUNDI -25℃~200℃

Fully enclosed system, single medium completes refrigeration and heating -120~350℃ ±0.5℃ ● Working temperatures from -120°C to +350°C ● Previously unachievable performance ●Intelligent temperature control…

SUNDI -45℃~250℃

SUNDI -45℃~250℃

● Working temperatures from -120°C to +350°C ● Previously unachievable performance ●Intelligent temperature control ● Maximum process stability and reproducibility ● Adop plate heat exchager, Pipeline heating, the fastest heat…

SUNDI -60℃~250℃

SUNDI -60℃~250℃

Ultra high temperature cooling technology can directly cool from a high temperature of 300℃[because only the heat transfer medium in the expansion chamber contacts with ox…

SUNDI -80℃~250℃

SUNDI -80℃~250℃

● Working temperatures from -120°C to +350°C● Previously unachievable performance●Intelligent temperature control● Maximum process stability and reproducibility● Adop plate heat exchager, Pipeline heating, the fastest heating…

loading…

已经是到最后一篇内容了!

LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor