LTS -60℃~80℃ Fluoride cooling heating system

Control de la temperatura durante la fabricación de semiconductores- Control del caudal12L/min~45L/min

- Precisión de la temperatura±0.1℃ @-60℃~-30℃

- Internal circulating liquid4L~10L

- Depósito de expansión10L~20L

- Lugar de origenChina

Descarga de datos del producto

Parámetros detallados

| Modelo | LTS-602 | LTS-603 | LTS-604 | LTS-606 | LTS-608 |

| LTS-602W | LTS-603W | LTS-604W | LTS-606W | LTS-608W | |

| Rango de temperatura | -60℃~-20℃ | ||||

| Precisión del control de temperatura | ±0.1℃ -60℃~-30℃ | ||||

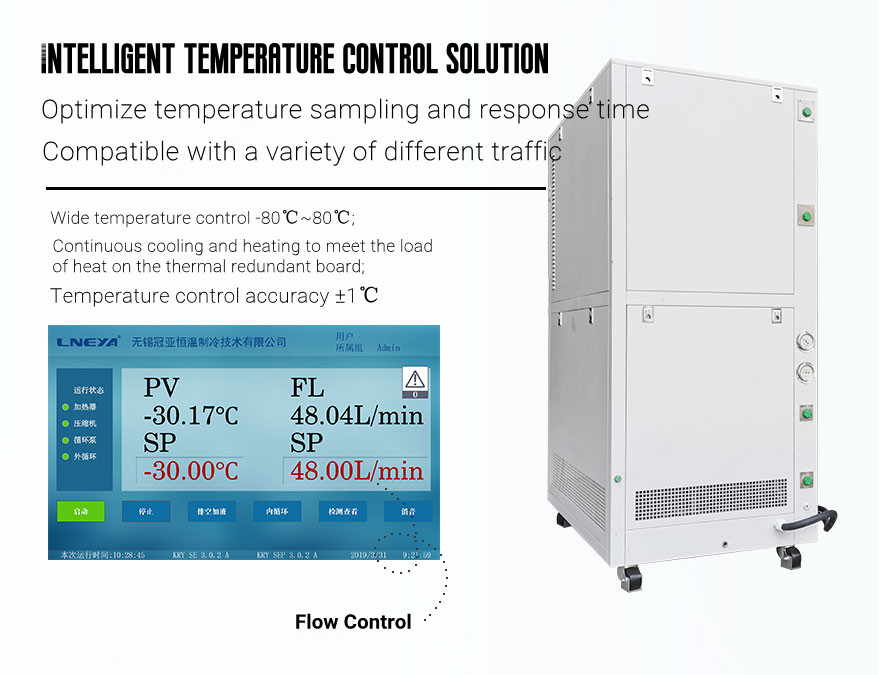

| Control del caudal | 7~25L/min | 12~45L/min | |||

| The flow control adopts frequency converter adjustment, and the speed is automatically adjusted according to the feedback signal of the flow sensor. The maximum pressure of the circulating pump is 5bar. | |||||

| Volumen de fluido circulante interno | 4L | 5L | 6L | 8L | 10L |

| Volumen del depósito de expansión | 10L | 10L | 15L | 15L | 20L |

| Visualización de la presión del sistema | The pressure of the refrigeration system is realized by a pointer pressure gauge (high pressure, low pressure) | ||||

| The pressure acquisition outlet position of the circulatory system is detected by a pressure sensor and displayed on the touch screen | |||||

| Controlador | PLC, algoritmo de control PID difuso, con algoritmo de control en cascada | ||||

| Control de la temperatura | Modo de control de la temperatura de salida del fluido caloportador | ||||

| External temperature sensor: (PT100 or 4~20mA or communication setting) control mode (cascade control) | |||||

| Carta de acuerdo | Interfaz Ethernet Protocolo TCP/IP | ||||

| Interfaz RS485 protocolo modbus RTU | |||||

| Internal temperature feedback of equipment | Equipment heat transfer medium outlet temperature, medium inlet temperature, refrigeration system condensation temperature, ambient temperature, compressor suction temperature, cooling water temperature (available for water-cooled equipment) | ||||

| Sistema de circulación cerrado | The whole system is a fully enclosed system, low temperature does not absorb moisture in the air, does not volatilize the heat transfer medium, and the low temperature automatically supplements the heat transfer medium into the circulation system | ||||

| Compresor | Emerson Copeland/Danfoss Scroll Flexible Compressor | ||||

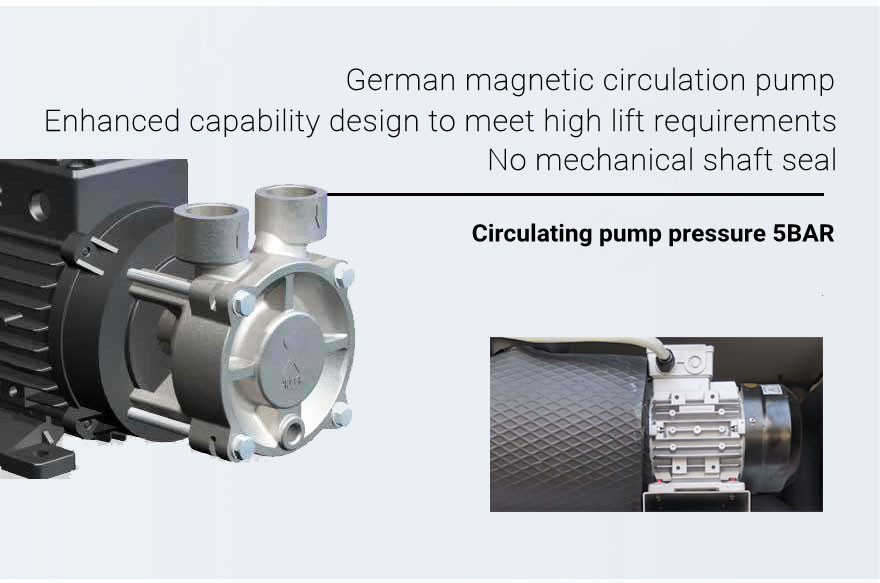

| Bomba de circulación | Magnetic circulation pump | ||||

| Evaporador | Intercambiador de placas | ||||

| Condensador | Micro channel condenser (air-cooled) | ||||

| Plate heat exchanger (water-cooled), special attention: clean factory water is required | |||||

| Accesorios de refrigeración | Danfoss/Emerson accessories (filter drier, oil separator, high and low pressure protector, expansion valve) | ||||

| Panel de control | Wuxi Guanya customized 7-inch color touch screen, temperature curve display\EXCEL data export | ||||

| Seguridad | With self-diagnosis function; phase sequence open-phase protector, refrigerating machine overload protection; high-pressure pressure switch, overload relay, thermal protection device and other security functions. | ||||

| Tamaño de la interfaz de entrada y salida | ZG1/2 | ZG1/2 | ZG3/4 | ZG3/4 | ZG3/4 |

Descripción del producto

It is widely used in the semiconductor manufacturing process to control the temperature of the reaction chamber, the temperature of the heat sink, and the temperature control of the non-flammable fluid of the heat transfer medium.

1. The pressure holding test of the medium circulation system is 7 bar.

2. Use high-quality magnetic pump without mechanical shaft seal.

Optimizar el muestreo de temperatura y la velocidad de respuesta, algoritmo de control de diseño especial, puede responder rápidamente a un control estable de la temperatura.

4. Enhance the design of the circulating pump capacity to meet the high-lift requirements of the system.

5. Continuous high-temperature cooling technology meets the requirements for stable operation when heat is loaded on the heat sink plate and requires cooling and heating constant temperature control.

6. In view of the volatile characteristics of fluorinated liquid, the joint design and system sealing design are strengthened to ensure the service life of the medium.

También pueden interesarle estos productos

Mandril serie MD

Mandril serie MD

-75℃ to 225°C Model MD-708 MD-712 MDL-708 Temp. Range -75℃~225℃ -75℃~225℃ -75℃~225℃ Temperature control accuracy ±0.1℃ ±0.1℃ ±0.1℃ temperature uniformity ±1℃ ±1℃ ±1℃ Flatness ±50um ±50um ±50um Tablet Size 200mm diameter d…

YQH 0℃~-75℃

YQH 0℃~-75℃

Adecuado para la recuperación de diversos gases volátiles COVs; Enfriamiento rápido, alta eficiencia, cumpliendo con diferentes requisitos de temperatura de condensación, baja temperatura puede alcanzar -75 ° C Proviene principalmente de la limpieza, pegamento ...

FLT-100℃~90℃

FLT-100℃~90℃

Refrigerador de un canal refrigerado por aire, diseñado principalmente para máquinas de grabado. Se utiliza para proporcionar un control independiente de la temperatura de las paredes laterales de la cámara.

FLTZ -45℃~90℃

FLTZ -45℃~90℃

Método de calentamiento dentro de 40 ℃ adopta un compresor de calefacción de gas caliente diseño totalmente cerrado, y la máquina funciona continuamente durante 24 horas El dispositivo de control de temperatura del semiconductor Chiller se utiliza principalmente para p...

loading…

已经是到最后一篇内容了!

LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor