Noticias

High and low temperature equipment manufacturers analyze expansion valve knowledge

The expansion valve is an important accessory in the high and low temperature integrated machine. The manufacturer tells you that there are various kinds of expansion valves, and different expansion valves have different differences. The high and low temperature integrated machine expansion valve mainly has two kinds of thermal expansion valve and electronic expansion valve. Generally speaking, the electronic valve is used more. According to the driving method, it is divided into electromagne...

Ver detalles

Funcionamiento eficaz de la máquina integrada de alta y baja temperatura

To ensure more efficient operation of the high and low temperature integrated machine, you should select the appropriate type of equipment and solve the problem in time. The selection of high and low temperature integrated machines requires some process requirements of the screw type high and low temperature integrated machine, such as cooling effect, cooling capacity, power and refrigerant type. According to the cold load and application considerations, it is easy to adjust and save energy. ...

Ver detalles

Maintenance of Glycol Cooling Heating Control System

Apart from the attention needed during the daily use, the regular check and maintenance of Glycol Cooling Heating Control System are also very important. In order to help all of you learn to use Glycol cooling heating more efficiently, Guanya Refrigeration sort out related maintenance, so that you can use it in time.Screw CompressorScrew compressor is a very important part of ethylene glycol refrigerator, and the compressor is directly related to the stability of the unit. If the compressor...

Ver detalles

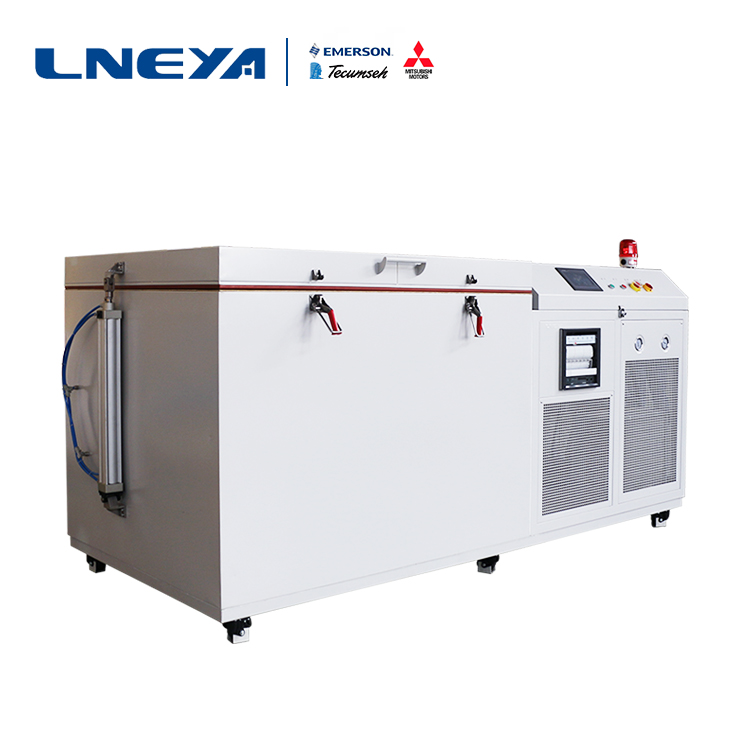

How to prevent the freezing pressure of the bearing quick freezing box from being too low?

In the refrigeration system of the bearing blast chiller, if the condenser installation is not in the enclosed space, the system's exhaust pressure (condensation pressure) tends to be lower in winter (or low temperature), which is often more common in the north. For bearing blasters, this is also the case for other equipment. The low condensing pressure of the bearing quick freezing box will make the expansion valve unable to obtain sufficient pressure drop at both ends, and it is difficult t...

Ver detalles

¿Cómo sustituir el compresor scroll del modelo de impactómetro?

In terms of different impact tester models, the configuration is also somewhat different. Among them, special care should be taken when replacing the scroll is a compressor. If the replacement is not noticed, the impact tester cannot be used. The prohibition of the impact tester is only carried out from the high pressure side when the scroll compressor is replaced. If it is only carried out from the high pressure side, the axial seal of the scroll will cause the refrigerant to remain on the l...

Ver detalles

LNEYA: Centrarse en el control de temperatura TCU para construir instrumentos chinos avanzados a nivel internacional

Wide temperature range: LNEYA's Chinese and production-grade multi-reactor refrigeration heating temperature control system (temperature control unit TCU) temperature range from -25 ° C to 200 ° C, of course, you can also customize other temperature ranges, but the main attention: temperature range (-50 ° C Up to 250 ° C). The temperature control unit TCU can control 2 to 20 reactors in a centralized manner. Each reactor can independently set the material temperature and jacket temperature to...

Ver detalles

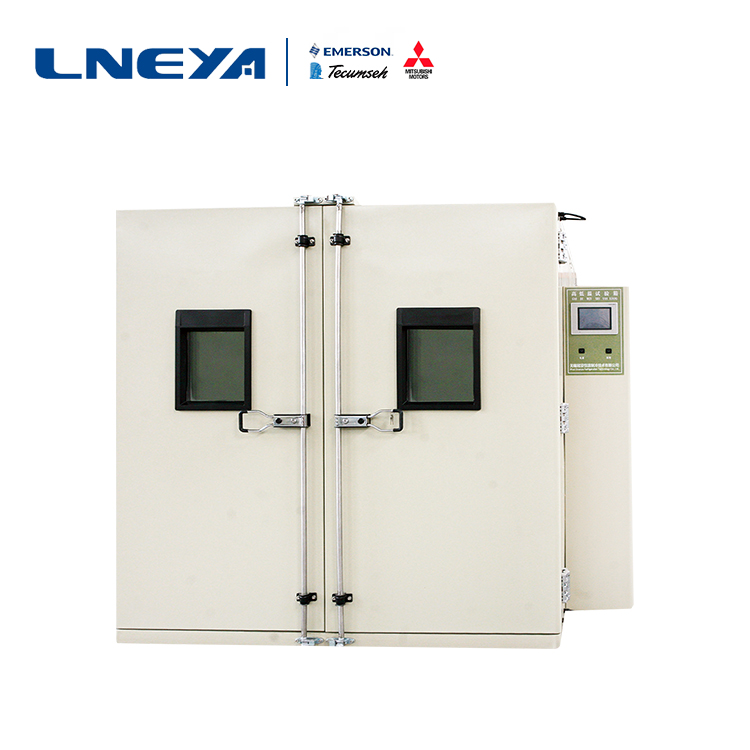

Step-by-step test box brand advantage description

The walk-in test box is developed and produced by LNEYA. It is specialized in pharmaceutical production technology and provides customers with various models of brands. Next, we will introduce the next step-in test box. Welcome to refer to and learn from. The walk-in test box is suitable for aerospace products, information electronic instruments, materials, electrical, electronic products, various electronic components in high and low temperature or hot and humid environment, to test their pe...

Ver detalles

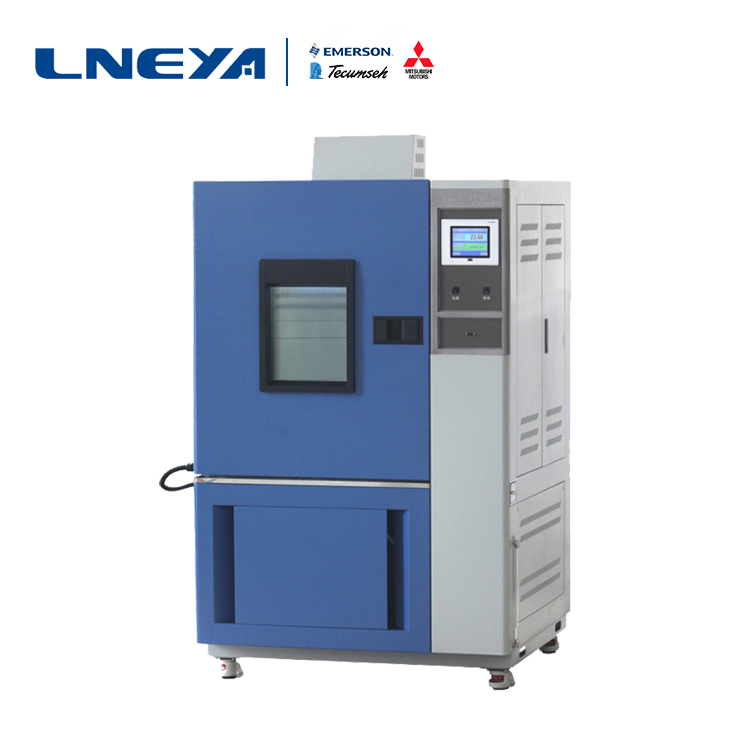

Qué hacer si el equipo de la cámara de pruebas de choque térmico no alcanza la temperatura fijada

The choice of the manufacturer of the thermal shock test chamber is related to the quality of the thermal shock test chamber. Once the quality is set, the temperature setting of the equipment will not be closed. What should I do if I encounter the temperature setting problem? The temperature set by the thermal shock test chamber is not up to the possibility that the heat exchange humidification tube is broken. You can either repair the factory or replace the new thermal shock test chamber dir...

Ver detalles

¿Cómo eliminar el fallo de una cámara de pruebas de choque térmico de gran tamaño?

As technology continues to advance and improve, LNEYA recommends strict requirements for operators of large thermal shock test chambers. If used improperly, operators need to be able to face and resolve these problems in a timely manner. A large thermal shock test chamber can be formed by the tank, the air circulation system, the refrigeration system and the heating system. When the high and low temperature experiments are carried out, the temperature rise is very slow, and the wind circulati...

Ver detalles

The principle of LNEYA chiller

Industrial chillers are commonly used to cool products and machinery for a variety of different applications, including injection molding, tools and die cutting, food and beverage, chemicals, lasers, machine tools, semiconductors and more. In most process cooling applications, the pumping system circulates cold water or water/glycol solution from the chiller to the process. This cooled fluid removes heat from the process and the warm fluid returns to the cooler. Process water is a means of tr...

Ver detalles LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor